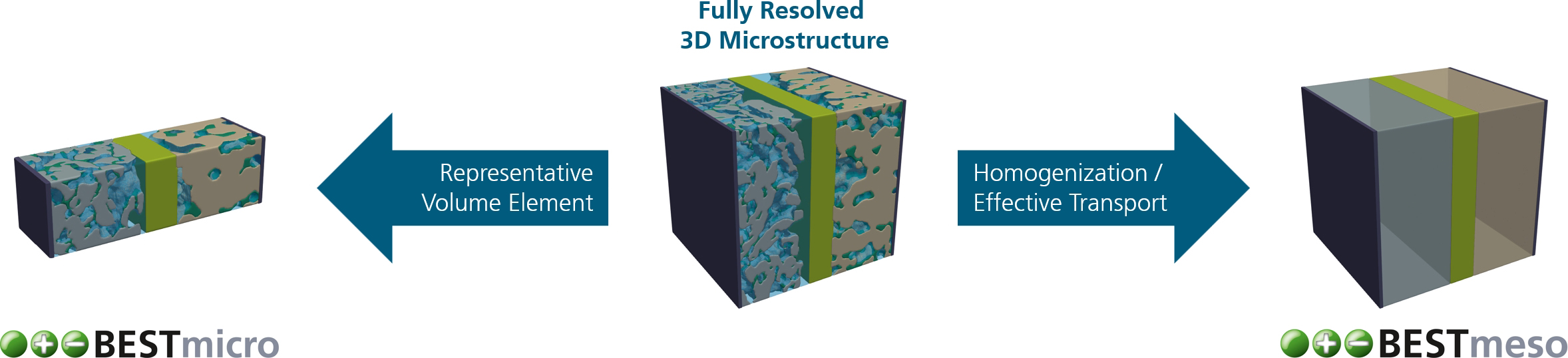

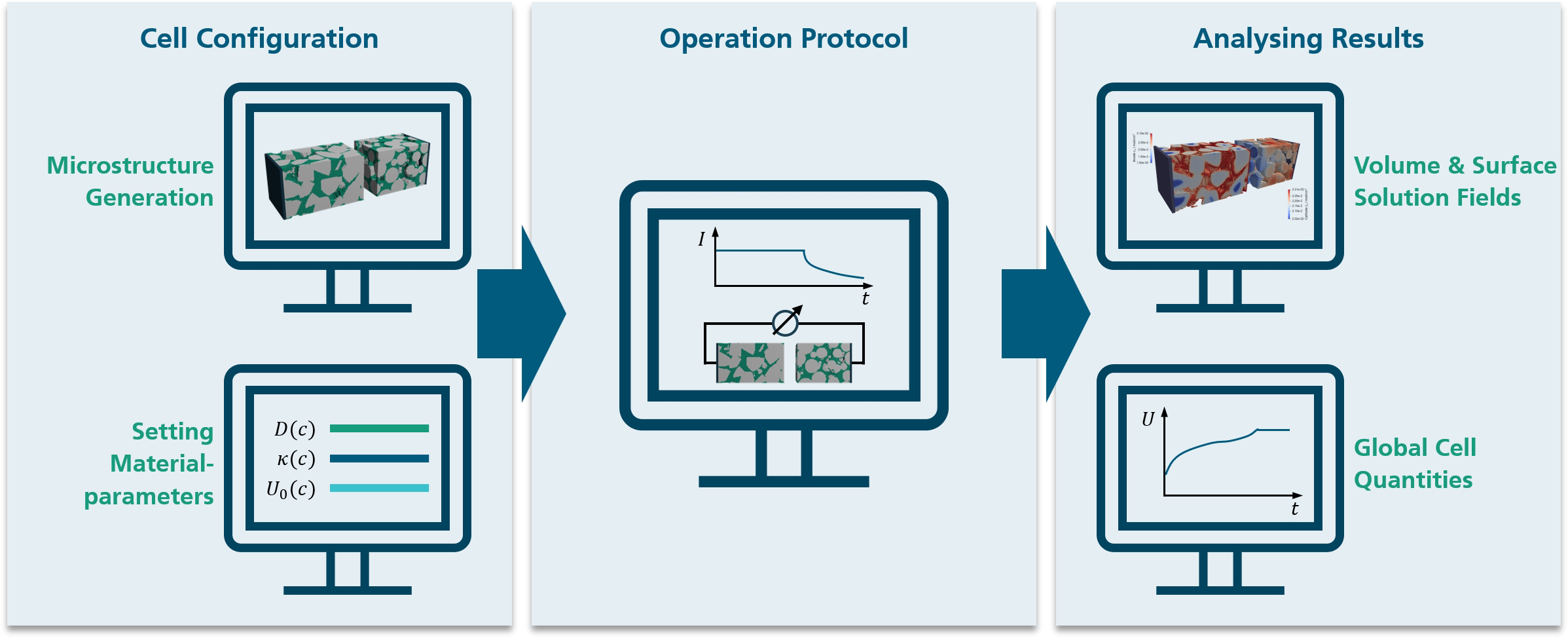

The Battery and Electrochemistry Simulation Tool (BEST) is our software environment for the physics-based three-dimensional Multiscale Simulation of lithium-ion batteries.

In contrast to phenomenological surrogate models, »physics-based« means we describe ion, charge and energy transport by physical laws formulated as partial differential equations, see Workflow.

We provide more information on the simulation model in the following publications:

- G. Less, J. H. Seo, S. S. Han, A. M. Sastry: Micro-Scale Modeling of Li-Ion Batteries: Parameterization and Validation, J. Electrochem. Soc. 159 (2012) A697-A704

- A. Latz and J. Zausch: Thermodynamic consistent transport theory of Li-ion batteries, Journal of Power Sources 196 (2011) 3296–3302

Our strength is to combine this kind of modelling with specifically developed, efficient numerical solvers that are implemented in C++ in our own software product BEST.

Privacy warning

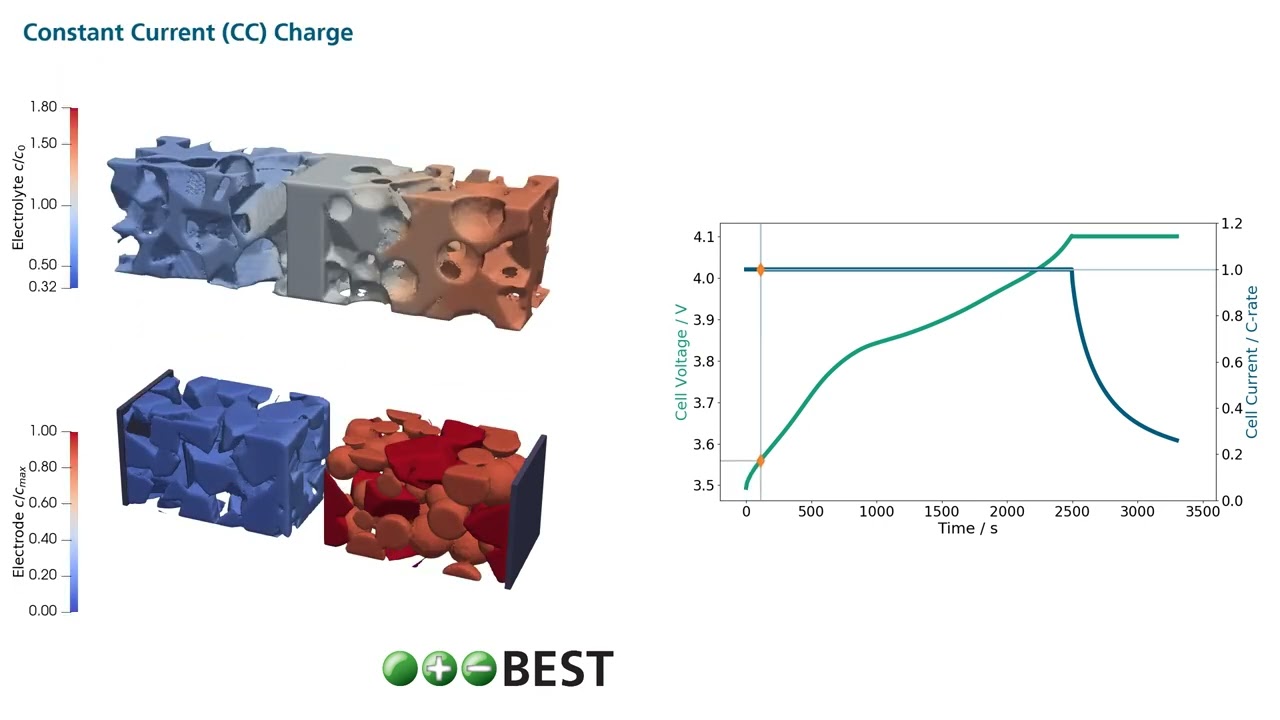

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyShowcase of a CC-CV charge simulation on a fully resolved microstructure performed within BEST. The three-dimensional solution fields on the left show the evolution of the lithium concentration over time within the electrolyte and electrode active materials.