Challenge Tensile Stress

The fundamental problem with gluing is the transmission of tensile stress, since concrete has a relatively small tensile strength. While the tensile strength of plates can be increased by different variants of reinforcements, no reinforcements that bridge the adhesive joint are included here.

Joints with teeth are considered to transfer the applied tensile stresses as shear stresses. For the evaluation and optimization of adhesive bonds of HPC plates precise voltage analysis procedures are necessary.

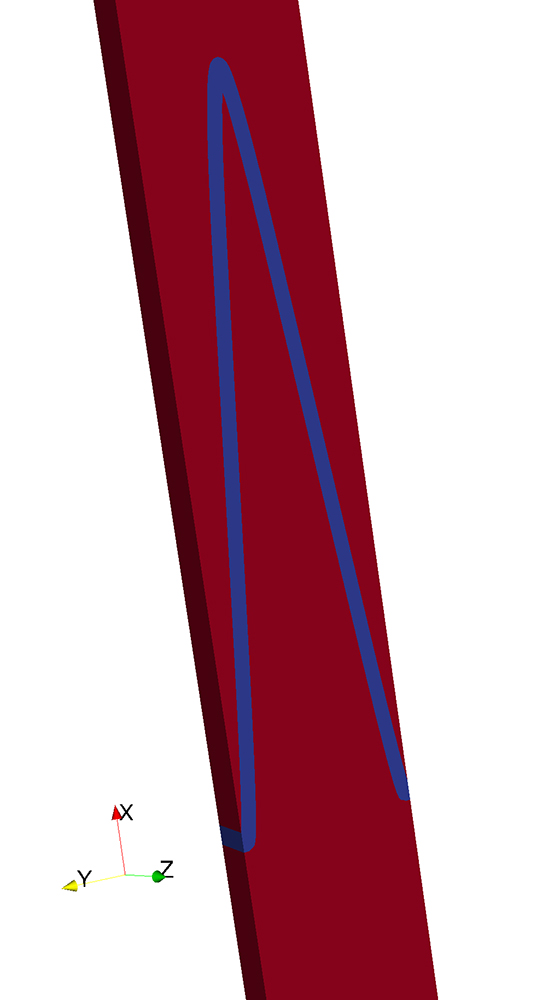

Rounded Triangular Teeth Optimal

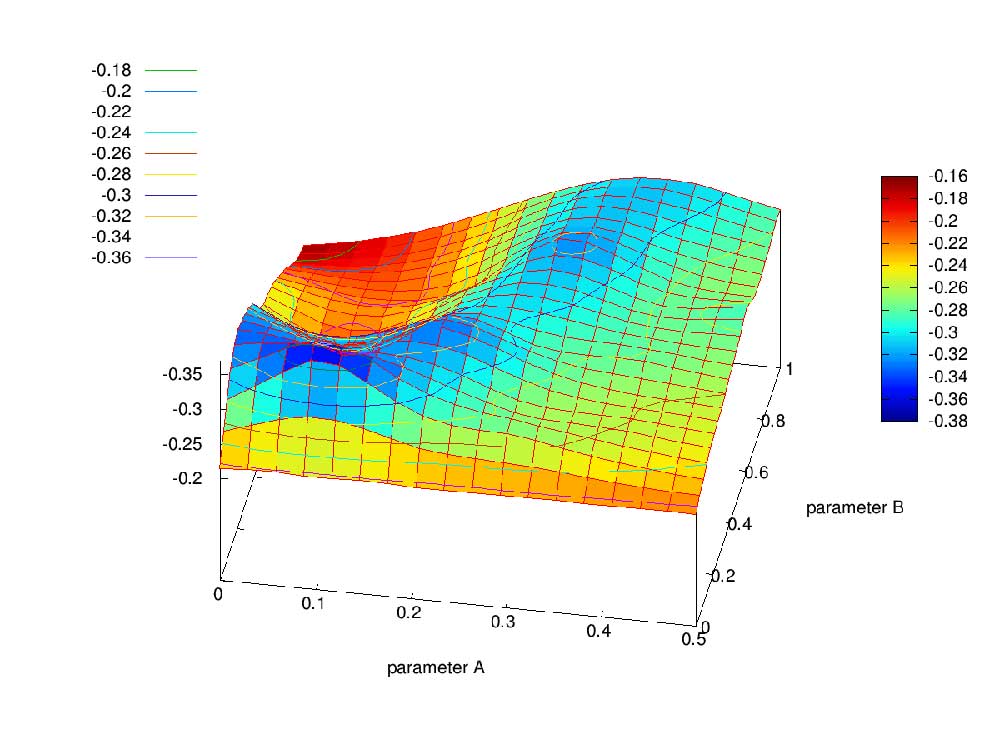

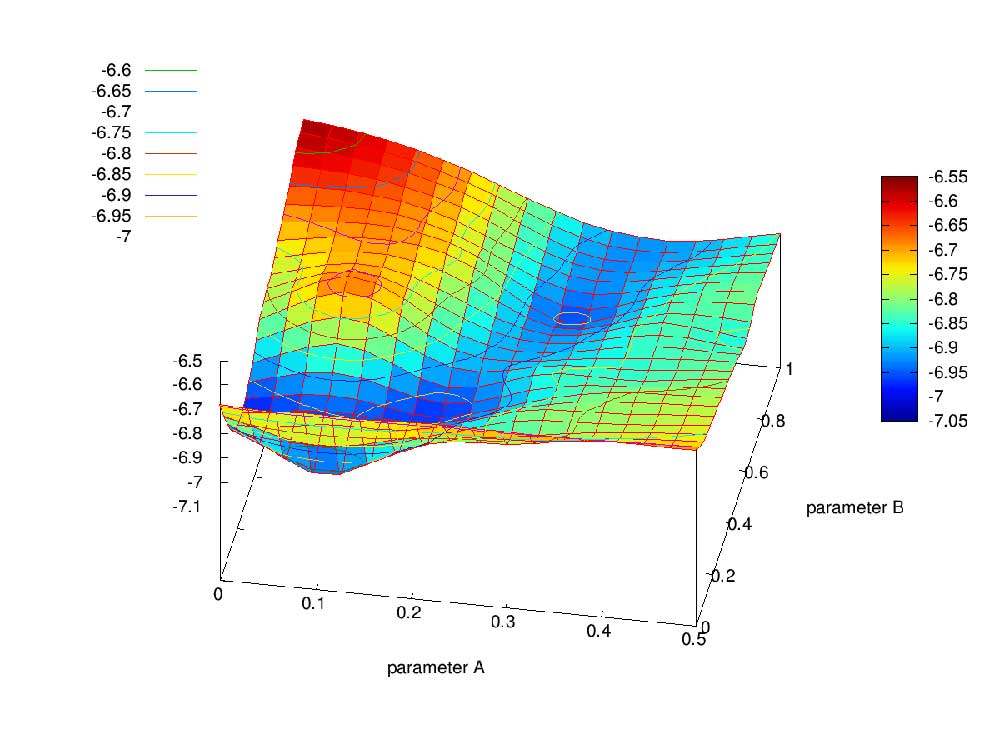

For the shape optimization of glued joints, it is useful to use the XFEM for structure analysis in order to precisely calculate the stresses and distortions in the joint area and to avoid complex new cross-links in the optimization loop.

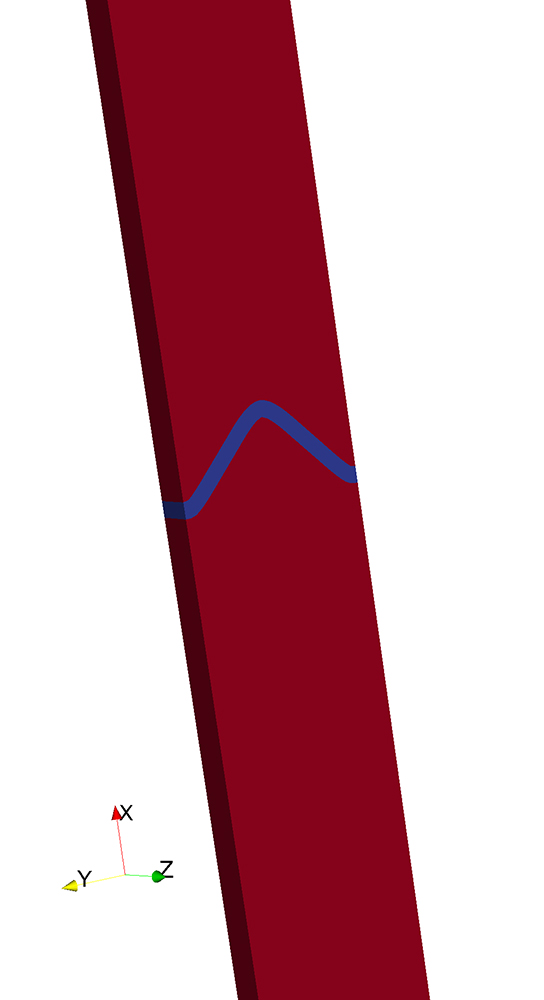

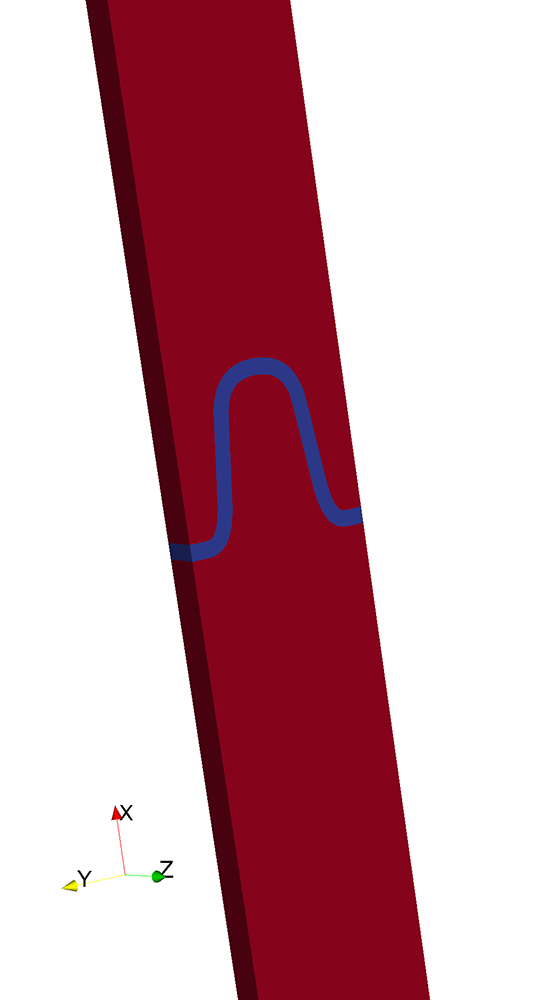

In the topology and shape optimization, a level set function (see figure) is used to implicitly describe the unknown free or determinable material boundaries, so that a uniform boundary description is provided for the combined topology and shape optimization. The result of the shape optimization for the transmission of tensile stresses is that rounded triangular teeth with a large depth are the most favorable.

The developed methods for structure analysis, topology and shape optimization are usable for any adhesive connections. The materials involved can have any anisotropic stiffness tensors and any structural loads can be considered.