Advantages Over Other Methods

An important advantage of GRAIN in comparison to particle-based methods like DEM is the treatment of the granular material as a continuum. This enables the simulation of fast, dilute as well as slow, dense granular processes with industrially-relevant material volumes and realistic particle sizes of different granulates and powders in the customary CFD context with similar computation times.

The microscopic interaction of particles becomes part of the continuum modelling here. In addition, the parallelisability of CFD processes can be achieved very effectively and we are researching intensively. These results can be applied directly to the method in GRAIN for the further reduction of simulation times.

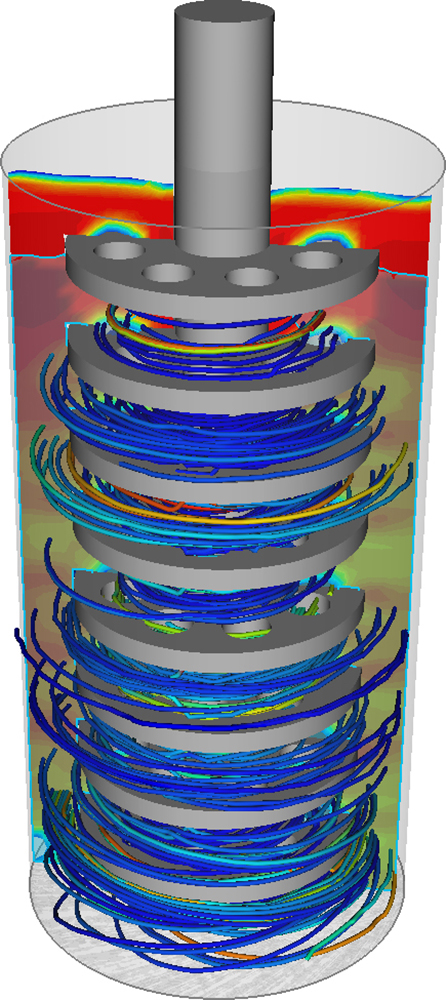

Interaction of Moving Components

In recent years the application field for GRAIN was greatly expanded once again by the interaction of moving components with granular media. Building on the initial success of promising testing, an industrial project for mixing machines with rapidly moving components was successfully completed.