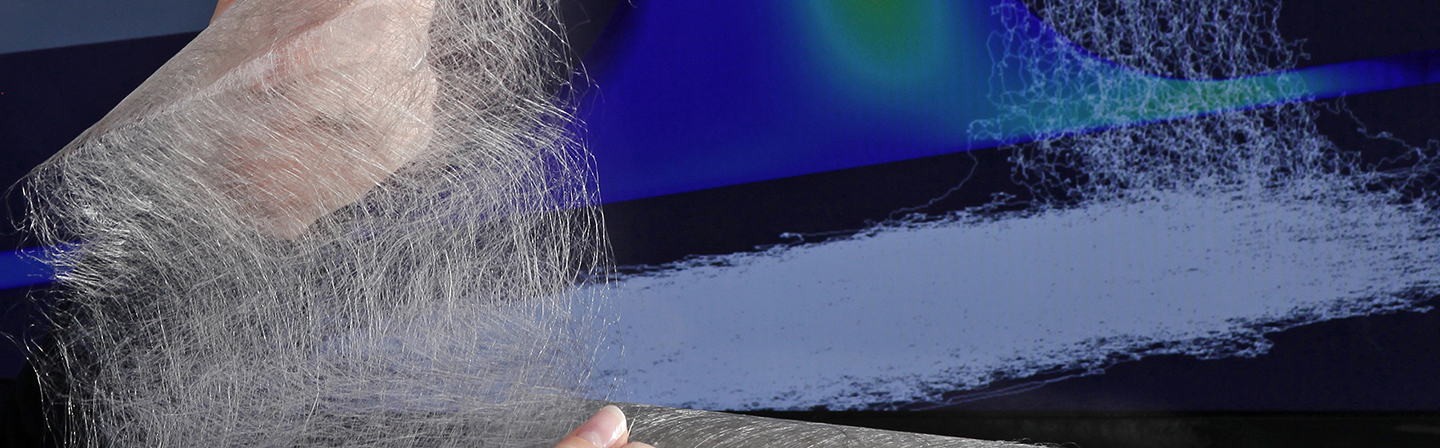

Mathematical modeling, simulating, and optimizing (MMSO) of flexible structures, such as the dynamics of threads, fibers and filaments is the main research focus of our team »Flexible Structures«. The main applications are industrial production processes of nonwovens.

Within the framework of long-standing research two software tools have been developed:

- the MATLAB/FLUENT toolbox VisFiD (Viscous Fiber Dynamics) that simulates a broad spectrum of spinning processes

- FIDYST (Fiber Dynamics Simulation Tool) for the simulation of fiber dynamics in turbulent flows. FIDYST generates virtual nonwoven structures and consequently allows its simulation-based optimization.

Both tools are applied in projects of industrial contract research. The further development picks continously up latest research results of ongoing PhD projects. One current reserach topic is the complete coupling of fiber and fluid dynamics by numerical homogenization strategies for the fiber dynamics.

Beyond these aspects the group »Flexible Structures« deals with several steps of pre- and postprocessing in the production of technical textiles. We offer our services both for producers and mechanical engineering companies.

Simulation of All Kinds of Production Processes

In the following you will find example projects from industry, but also publicly funded projects on a wide variety of processes in the field of technical textiles. One focus is on the simulation of spinning processes. Considering the methodological aspect, the use of ML (Machine Learning) also plays an increasingly important role in our work with the textile industry.