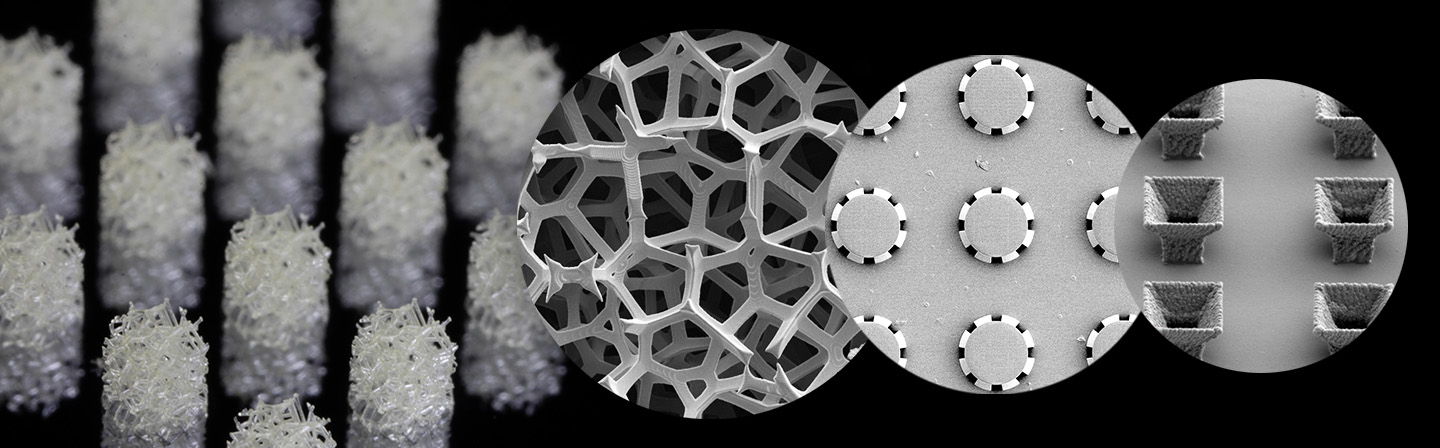

In the field of activity »3D Micro- and Mesoprinting« we produce almost arbitrarily complex, high-resolution prototypes and components, e.g. for biomedical and high-frequency applications or for validating model calculations.

We map the complete process chain – from design to the functional component. Depending on the geometry to be realized, we use a combination of additive laser writing and subtractive ablative processes such as ablative sputtering, as well as micro-ablation processes for repetitive geometries. The cross-scale approach enables us to manufacture components with cm3 volume at structural details of less than one micrometer.