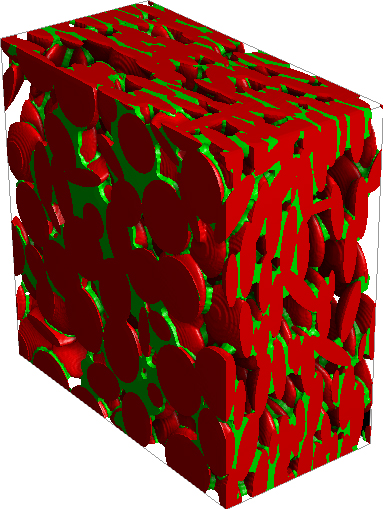

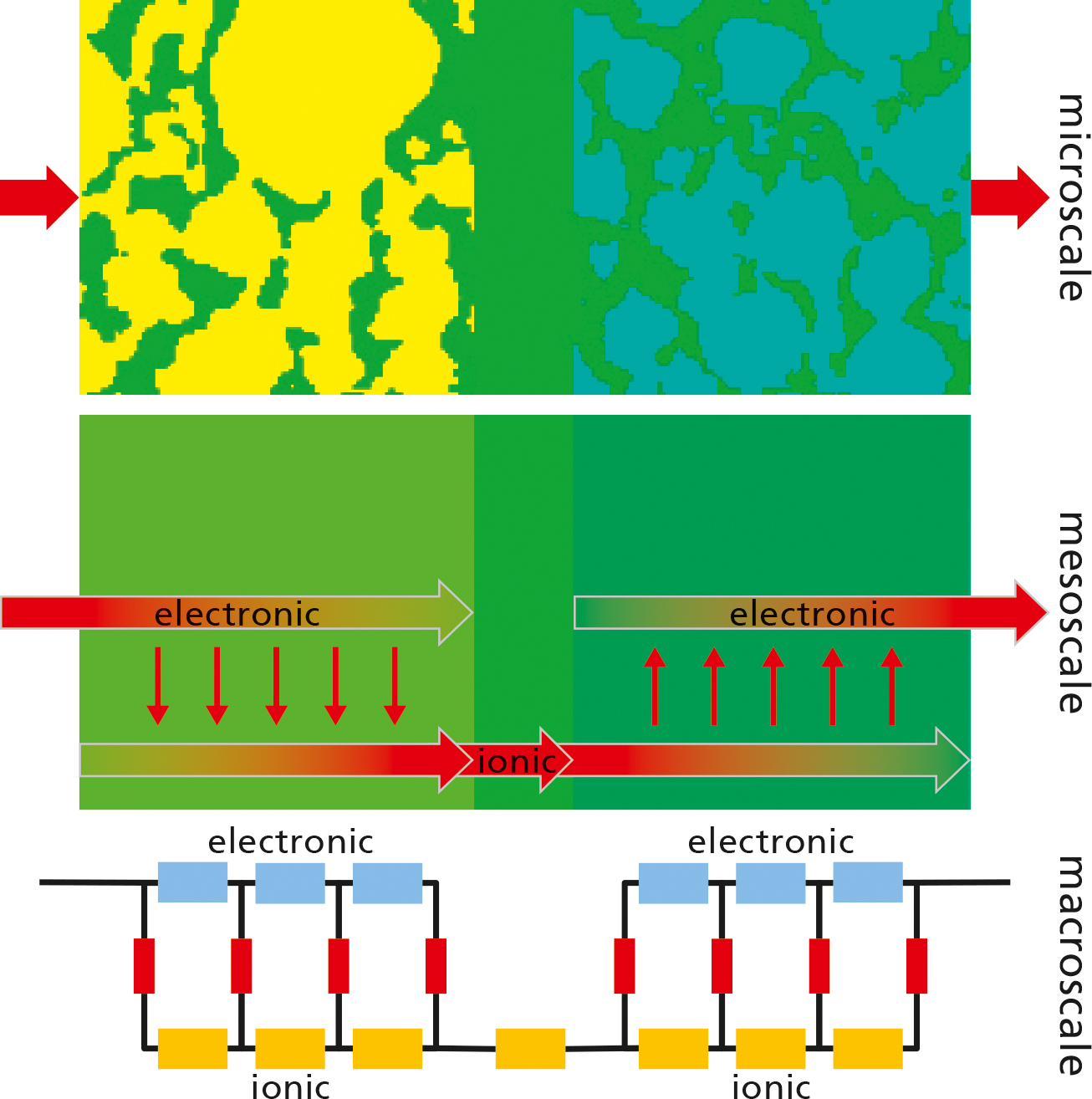

The BEST (Battery and Electrochemistry Simulation Tool) simulation software developed at our institute is currently being used by experts in the automotive industry for the development of lithium-ion batteries. Among other things, it is used to evaluate fundamental design decisions on the pore scale of the electrodes and the battery cell. BEST is a technology leader in this field, but it is restricted so far to the usual lithium-ion batteries and a small, highly specialized group of applications.

New electrode materials and electrolyte concepts such as solid electrolytes are only partially covered by current simulation technology. In addition, the questions of aging and damage of the battery cell over the life cycle are only in part considered so far and the use of the detailed battery models in the battery management system is currently not universally possible.