EMILIE stands for Embedding Machine Intelligence Logic and IT Security into Edge Devices and is used on site, e.g. in the technical center of Gebrüder Pfeiffer SE. The company specializes in material processing and offers mills and rollers for various substances, such as cement and other construction materials.

Local Data Storage Thanks to Edge Computing

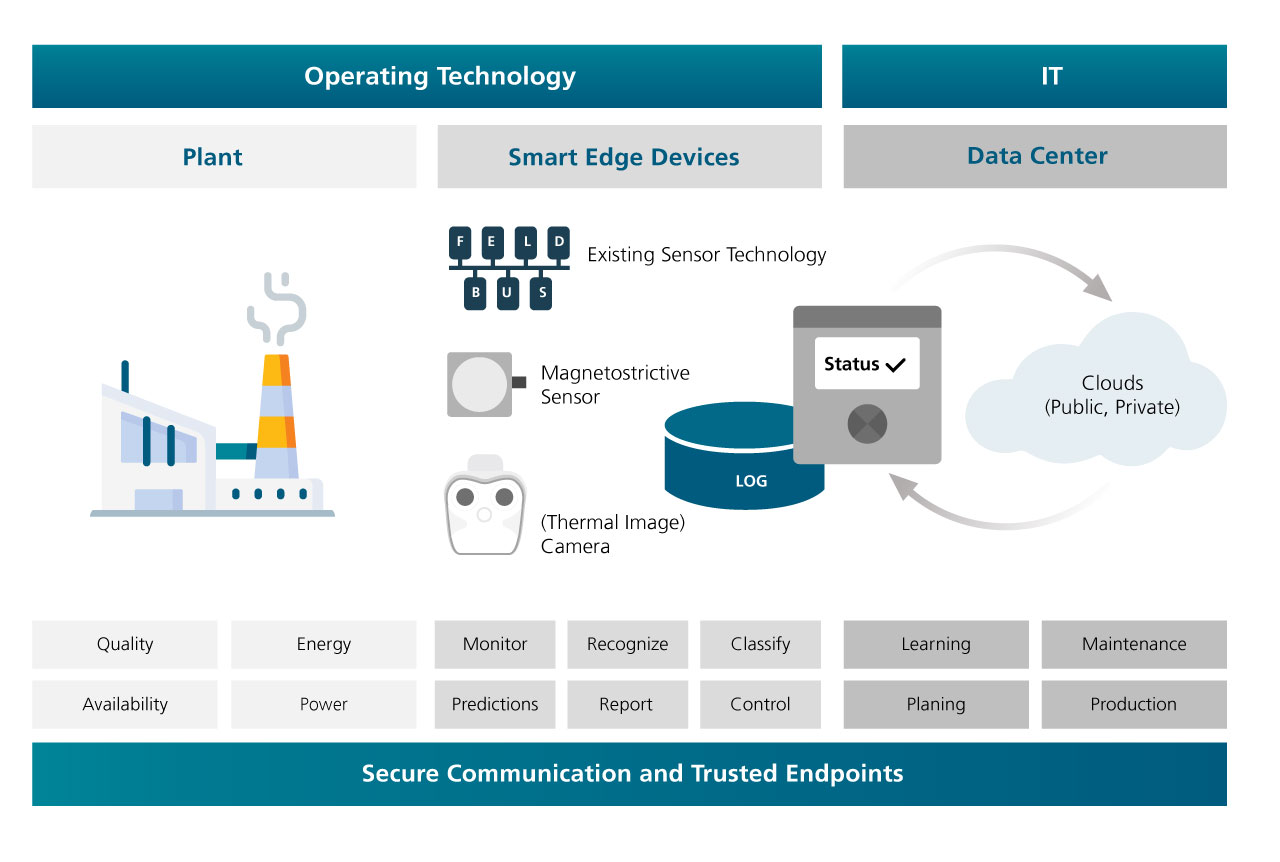

In the age of the Industrial Internet of Things, edge computing is becoming increasingly important due to security and efficiency. »Here, data is not processed in remote data centers or the cloud, but at the edge of IT and as close to the sensor as possible, in the control cabinet on the DIN rail,« explains Dr. Benjamin Adrian, project manager at Fraunhofer ITWM.

The edge devices in the project EMILIE are either integrated into magnetostrictive sensors and high-resolution cameras or connected by cable via edge gateways. This enables camera-based vibration monitoring, in which observed pixels serve as acceleration sensors, so to speak – torque, angle of rotation, and speed are recorded contactlessly, magnetostrictively via a single sensor.

Fewer Vibration, More Efficiency

With the cement mills of Gebrüder Pfeiffer SE, the Edge devices are tested in real production operations. »When crushing construction debris, large forces act that cause the mills to vibrate and accelerate their wear. We want to prevent this by optimizing machine settings with a digital twin and transferring them to the real mills,« Benjamin Adrian describes the project goal.