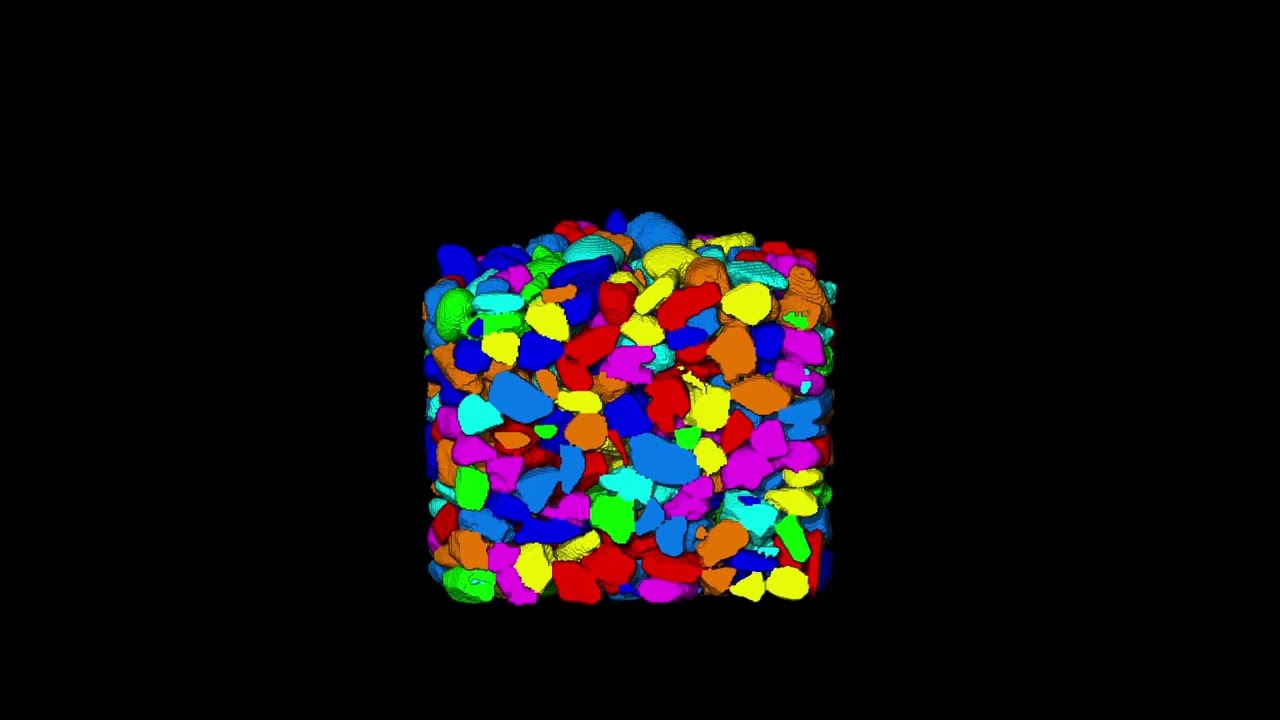

In the »KIBi« project, we are working with our partners to develop an AI-supported process that automatically separates and characterizes aggregates in CT images, thereby simplifying and improving quality assurance and production control in the building materials industry. It is part of a special transfer program run by the Fraunhofer-Gesellschaft and the German Research Foundation (Deutsche Forschungsgemeinschaft DFG).

Aggregates have a decisive influence on the properties of concrete and many other building materials: the choice of grain size, composition, size distribution, and grain shape are crucial for the end product. In order to control these influences in a targeted manner, it is necessary to characterize the grains reliably and reproducibly.

Currently, grain shape is characterized by screening with bar sieves or manual measurement. Other methods, including automated ones, have not been able to establish themselves in production because they are still too complex, too prone to errors, and not flexible enough.