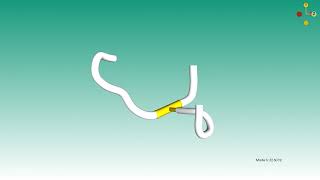

At Fraunhofer ITWM, we develop methods for simulating cables, hoses, and entire piping systems quickly and realistically. We support companies in virtual product development – from assembly planning to operational simulation in vehicles.

With our expertise, we develop software products that enable users to identify potential problems early on in the digital development process. This allows us to create space for solutions before they arise in practice. In this way, we help to save time and costs while increasing quality. We are happy to adapt our methods to your specific requirements.