Optimization of Filtration Properties

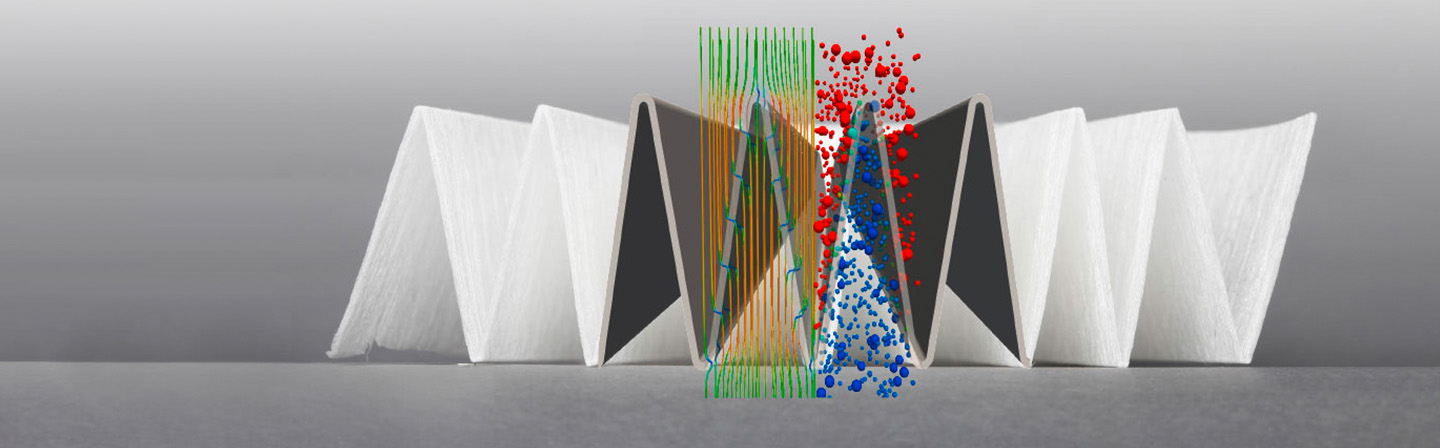

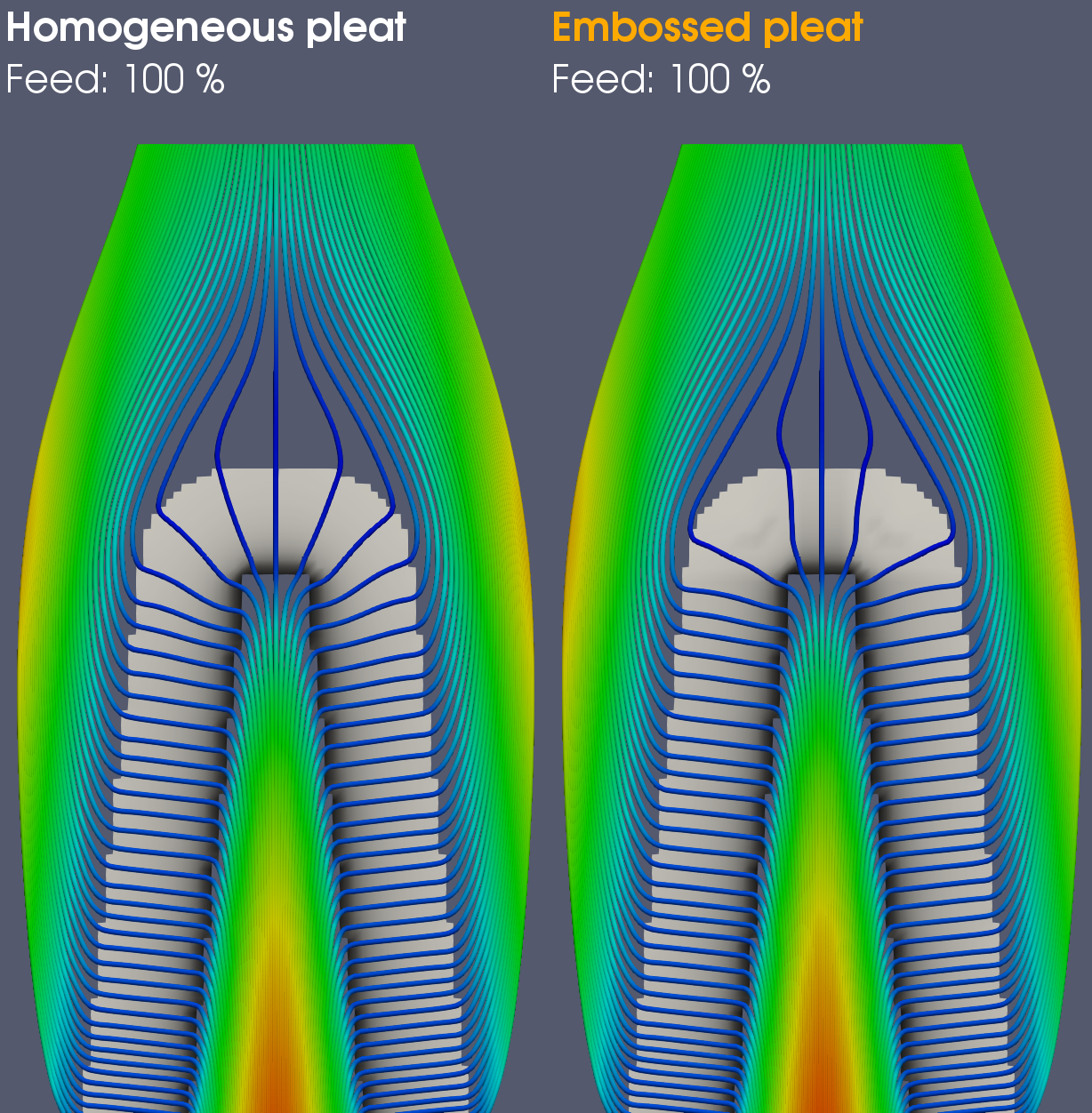

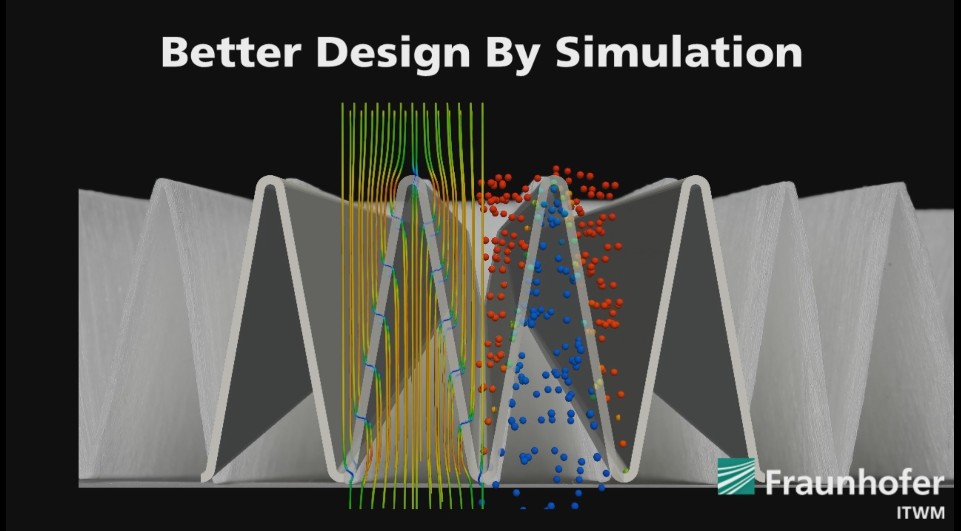

In terms of filter performance, the pleat shape should ensure a long lifetime and high dust holding capacity (DHC). For the computer-aided prediction of these properties, we develop

- efficiency models for the numerical simulation of the loading of the pleat (depth and cake filtration)

- and permeability models to account for the change of the flow resistivity during simulation and therefore, the evolution of the differential pressure.

The model parameters can be deduced from flat sheet measurements performed for the filter media used in the pleated filter. In particular, by performing computational what-if studies for multi-layered media, optimal choices for the selection of filtering materials are possible without the need for real-world prototypes.

Optimization of Filtration Properties

In terms of filter performance, the pleat shape should ensure a long lifetime and high dust holding capacity (DHC). For the computer-aided prediction of these properties, we develop

Optimization of Filtration Properties

In terms of filter performance, the pleat shape should ensure a long lifetime and high dust holding capacity (DHC). For the computer-aided prediction of these properties, we develop