Due to their low density, foams are attractive for a wide variety of applications. They are used as shock absorbers (crash absorption) or for sound and heat insulation and can be found as seat structures in all kinds of vehicles (wheelchairs, car seats, aircraft seats).

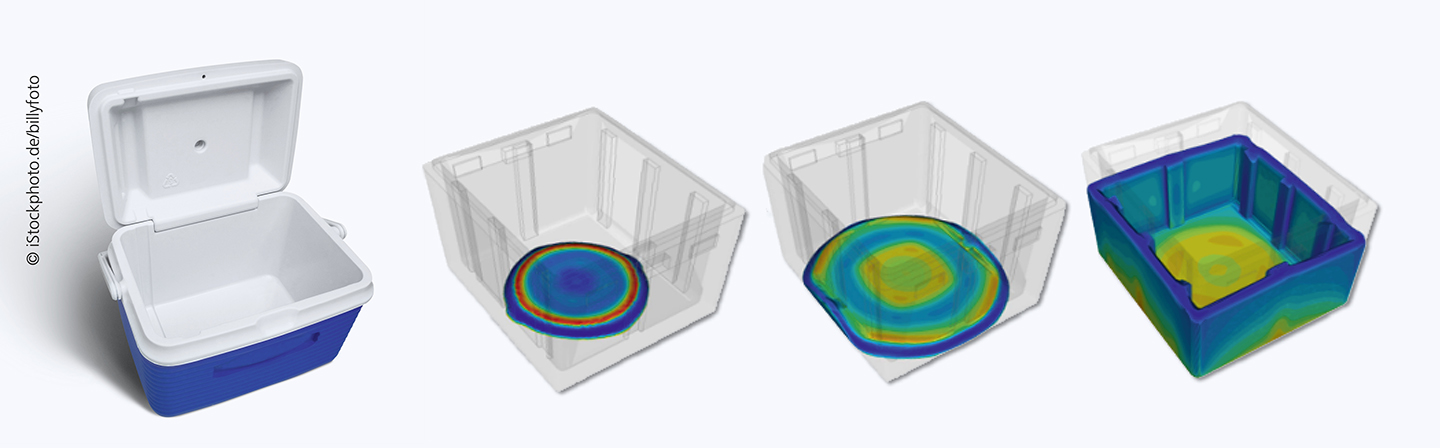

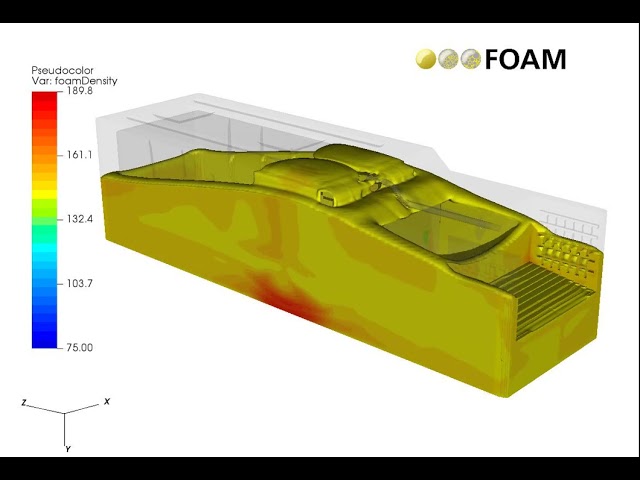

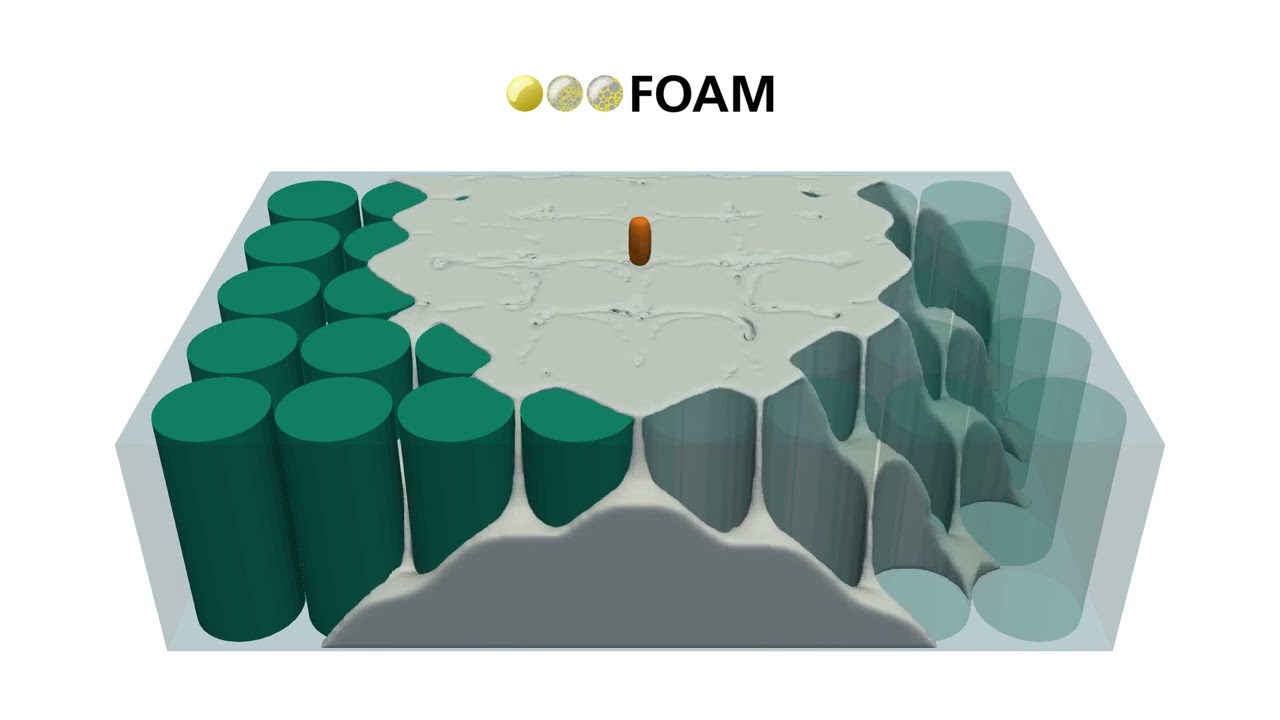

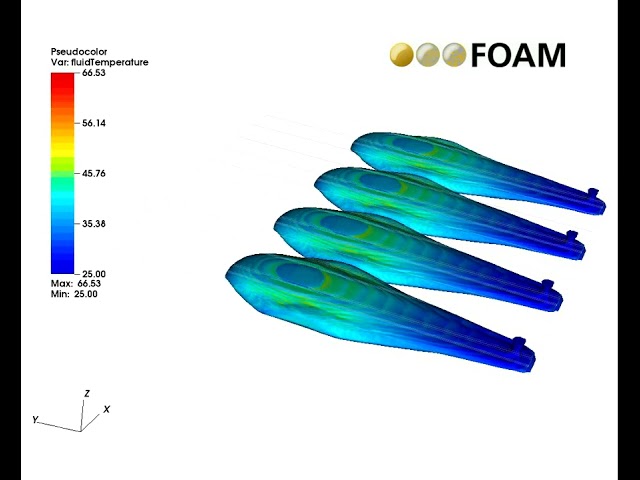

Our software solution FOAM simulates the expansion process of foams in arbitrary geometries and offers the possibility to calculate in advance the foam formation process as well as the resulting foam density in closed shapes.

FOAM is an excellent simulation tool for designing and optimizing foamed foam components and parts. The simulation with FOAM can also be used to predict complicated mold filling requirements such as

- Venting points

- Position of the inlet, path movement of the injection nozzles

- the amount of material required to fill the cavity

- the need to avoid the inclusion of gas in the mold

Targeted expansion tests in cylindrical containers with integrated temperature measurement are sufficient to estimate the necessary parameters for the foam model. On this basis, the model parameters are determined automatically and used directly to simulate complex foam filling processes.