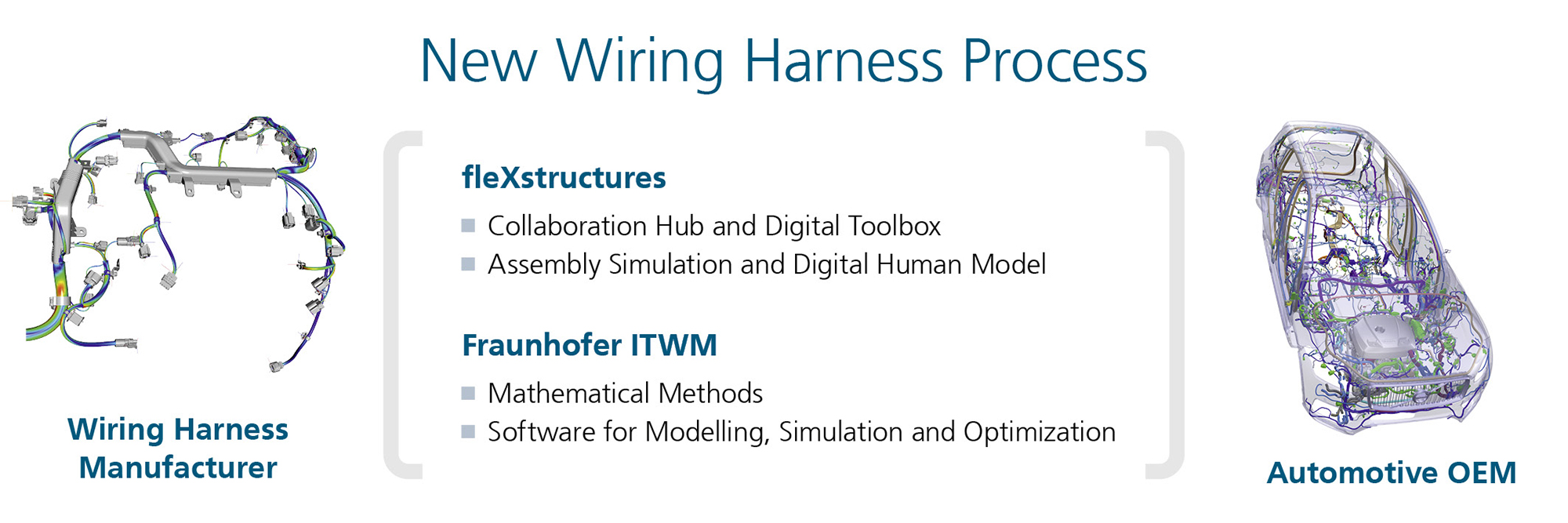

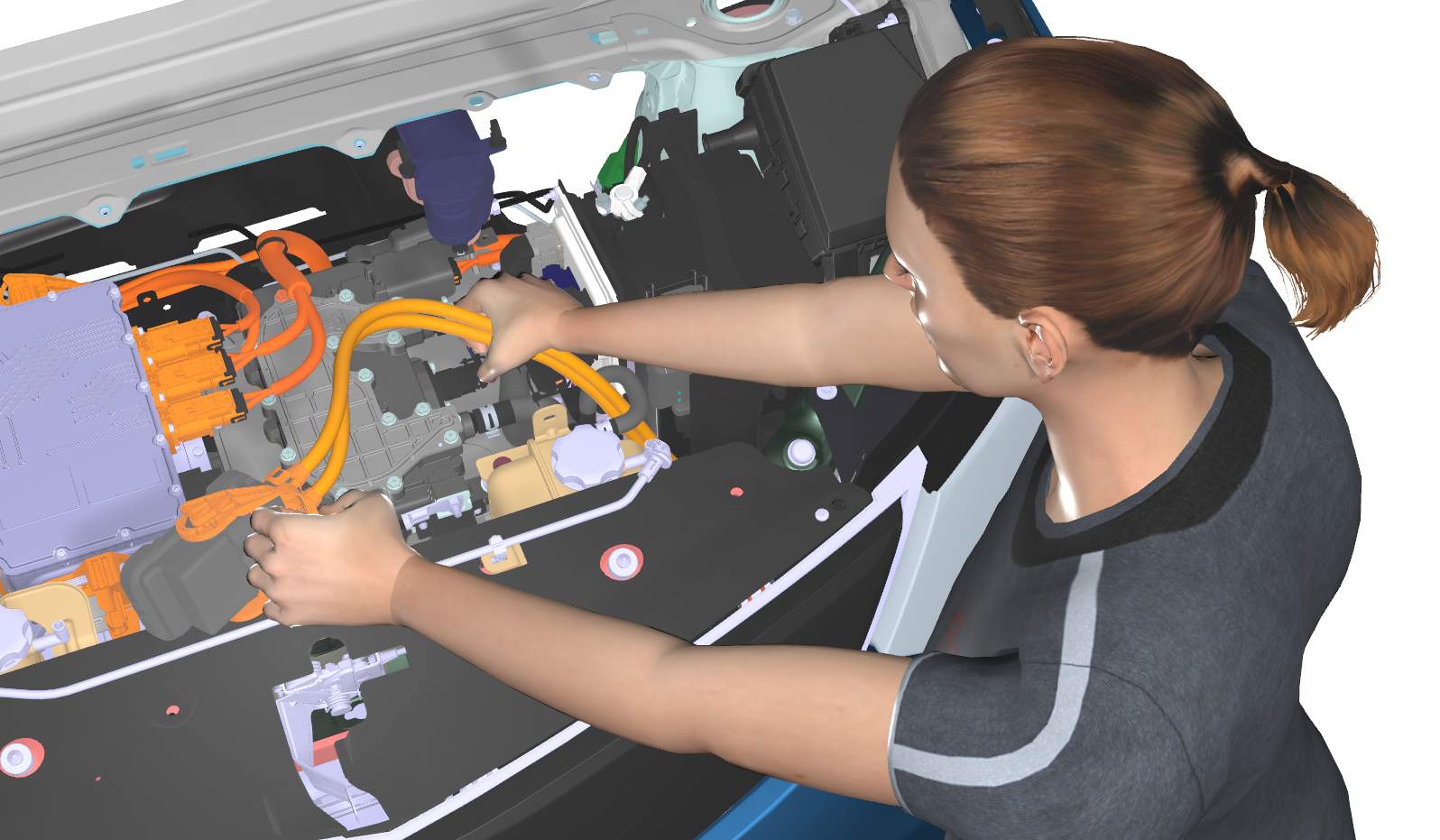

In the project »BordNetzSim3D« funded by the German Federal Ministry of Economics and Climate Protection (BMWK), we are working with our partners to provide for the first time an end-to-end digitized platform and toolbox that enables companies to develop simulation-based vehicle electrical systems. Virtual product development – from the concept phase to production – paves the way from the hardware-oriented to the simulation-based digital wiring system process.

Optimizing a Complex Wiring System Means Optimizing Cable Harnesses

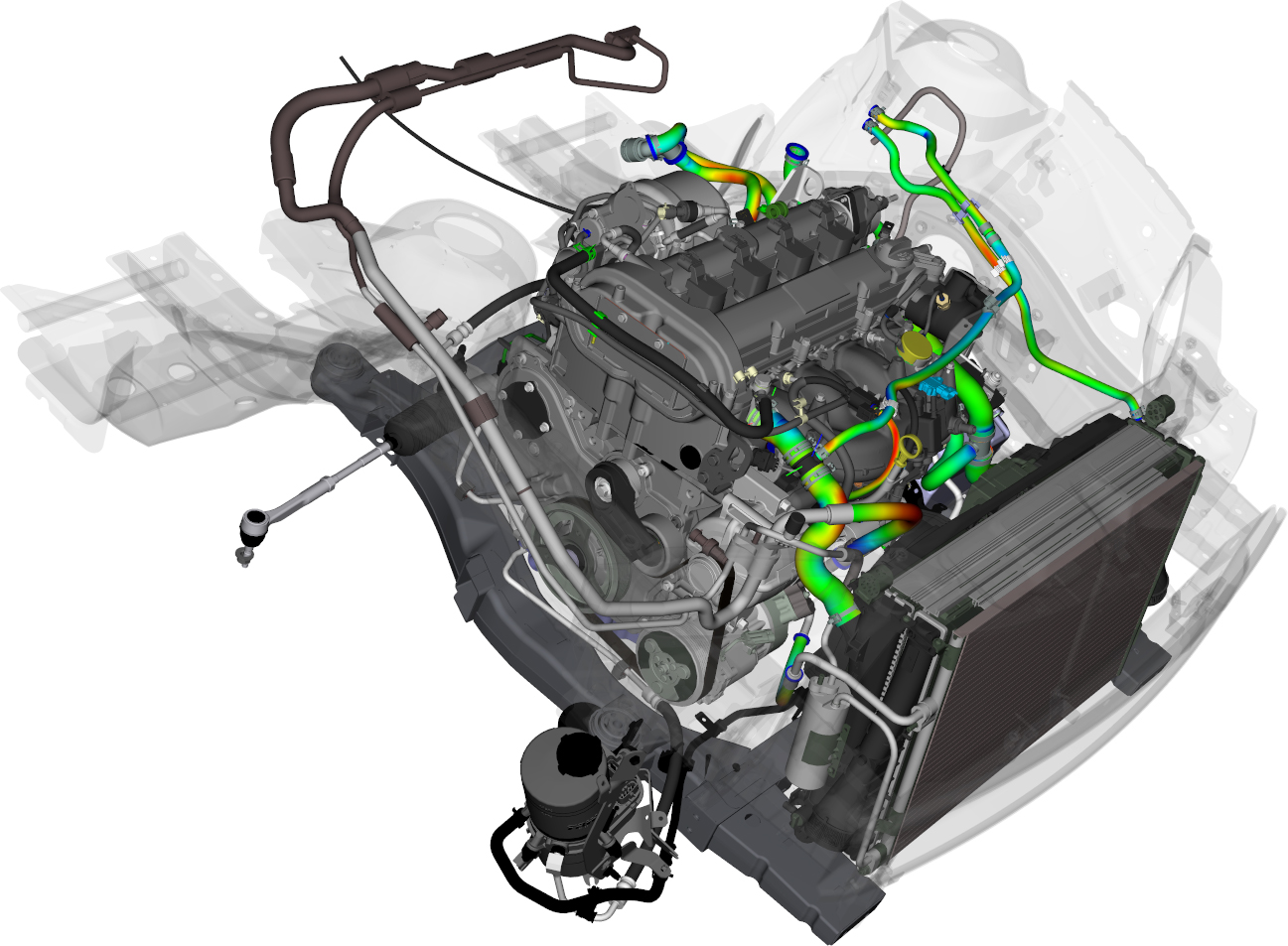

The on-board network is the term used to describe the totality of all electrical and electronic components in vehicles. It is already the nervous system of modern vehicles and is becoming increasingly important as a result of current developments – especially new drive and vehicle concepts (e-mobility), driving assistance systems and the networking of vehicles and/or autonomous driving. In the future, vehicles will be equipped with more and more electrical components and functions, and today's onboard networks are highly complex constructs. They largely consist of cables or cable harnesses with total lengths of several kilometers.