Production of Filter Systems

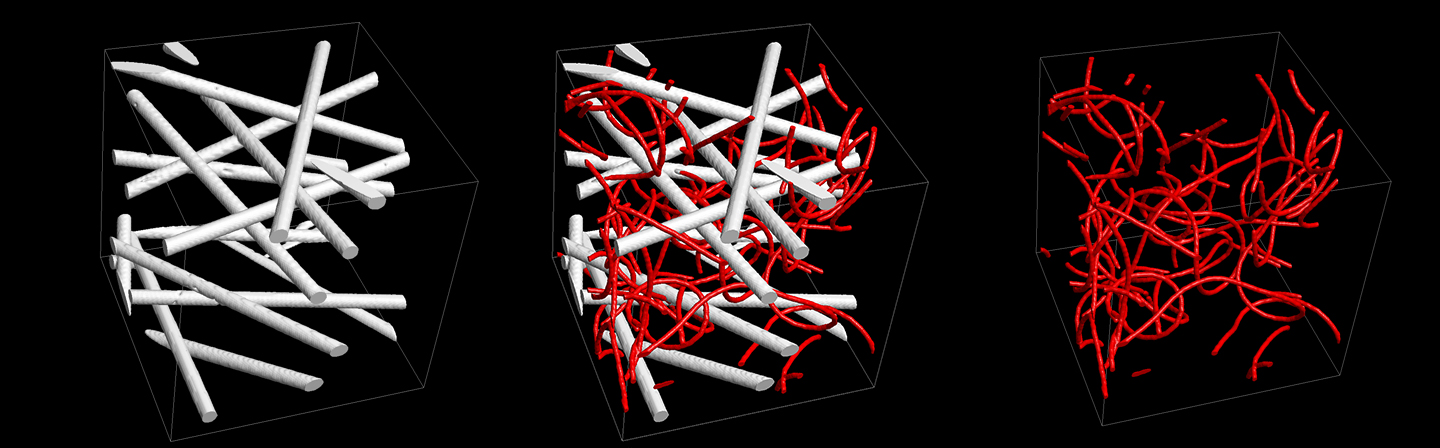

Respirable fine dust emissions are subject of environmental discussions since they bear great risks of disease. The project NaBlo aims to reduce the exposure to fine dust particles by new filter systems based on nano fiber meltblown media.