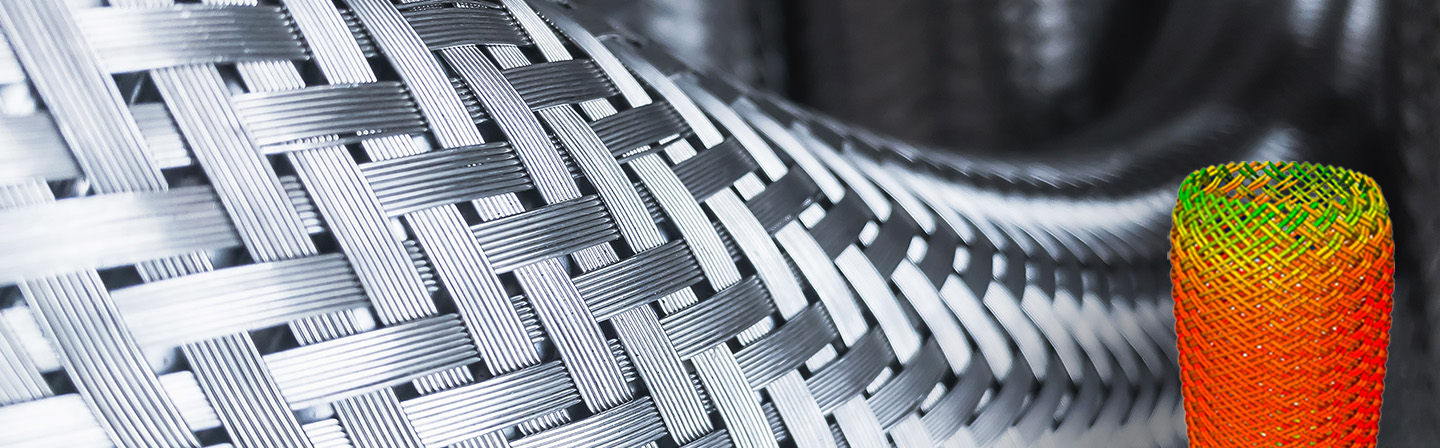

Using the latest mathematical models, the TexMath software tool has recently started calculating braids and, in particular, braided tubes. These are used in many industries and applications: cables that are wrapped with a textile tube for their protection and stability, a defective pipe that is repaired by a textile tube, but also stockings and bandages – TexMath provides suitable simulations for all of these.

Simulate Wrinkling in Tubes With TexMath

Texmath Calculates Braided Tubes

TexMath calculates tube properties for any textile structure. Knitted and braided tubes, for example, can be compared in terms of their strength. In addition, it is possible to predict how certain folds or bends affect the material.

Numerous Applications for Tubes and Braids

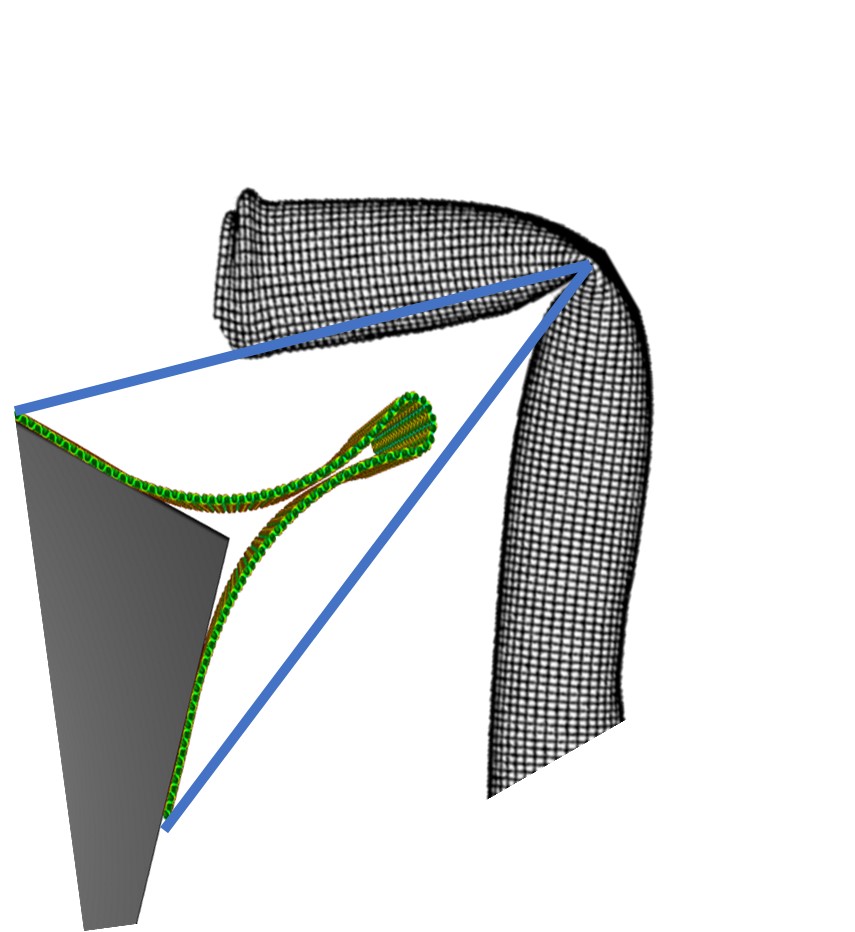

Tubes are used in the construction industry, medicine or the automotive industry. For example, our mathematical models simulate the wrinkling of drainage tubes used for pipe rehabilitation.

Dimensional reduction methods can be used to predict the wrinkle shape as a function of tube radius, pipe curvature, tube thickness and effective textile properties. Sealing tubes can also be simulated and verified.

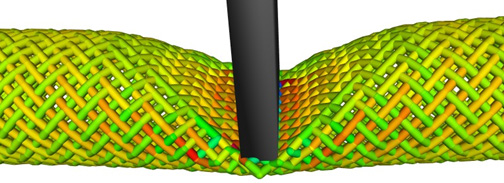

The strength of composite tubes, which consist of a plastic or rubber matrix and are wrapped with a textile structure, can also be simulated. In addition, simulation of the impregnation process of a textile is possible. The applied layer can, for example, be located between two plastic layers or it can be applied from the outside.

Simulating Loads on Textile Reinforced Composites

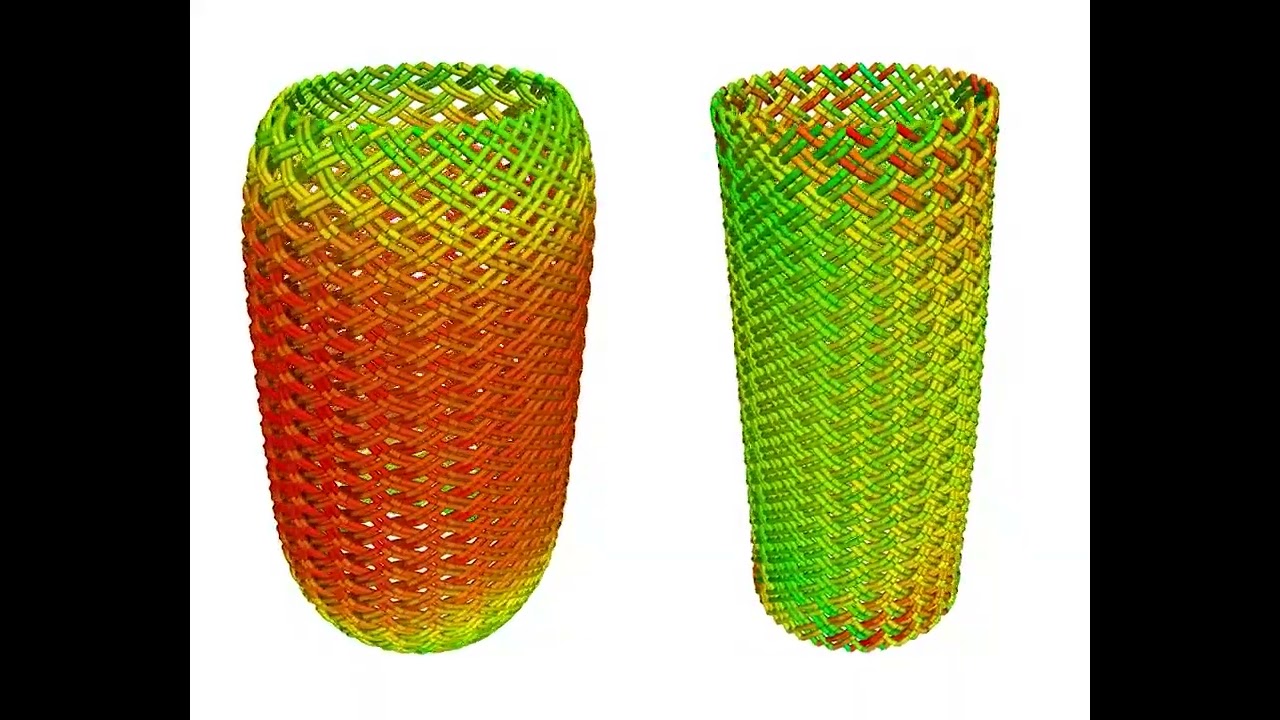

When applying loads, it is particularly important to consider the textile and plastic behavior separately, to include their interaction and to consider proper strength models, as well as all the scales involved, down to the yarn contacts. In this way, the effect of forces on a composite material can be better understood. Further, it is important to understand the effects of ultimate failure of a tube. With this knowledge, one can optimize the tube design at all scales.

Texmath Optimizes Product Development

Here you can test optimal combinations of textile structures in any textile class, i.e. , single or multi-layer woven, braided, knitted, knitted fabrics, and yarns. The fracture criteria differ depending on the stiffness differences between the tube and the filling material. Here TexMath can model and simulate different scenarios and find optimal yarns and patterns for each textile and matrix class.

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyCalculate the dynamic behavior of braided tubes with TexMath.