The increasing integration level of nanoscale semiconductor circuits as well as the connection of various sensors and actuators significantly increase the complexity and sensitivity of the system behavior of many electronic and mechatronic applications.

Many task settings therefore require a mathematical modeling of the respective system, e.g. by the method of finite elements. Due to the often very high model complexity, model-order reduction techniques are used to generate the required real-time capability. Then, the resulting models can be the basis of model-based controllers or state estimators, as well as be used to simulate the corresponding components by means of simulation in the software-in-the-loop or hardware-in-the-loop setting.

Active vibration damping or noise reduction in automotive applications, signal tracking for test bench or temperature controls and controller design for smart energy applications are typical tasks in the area of control.

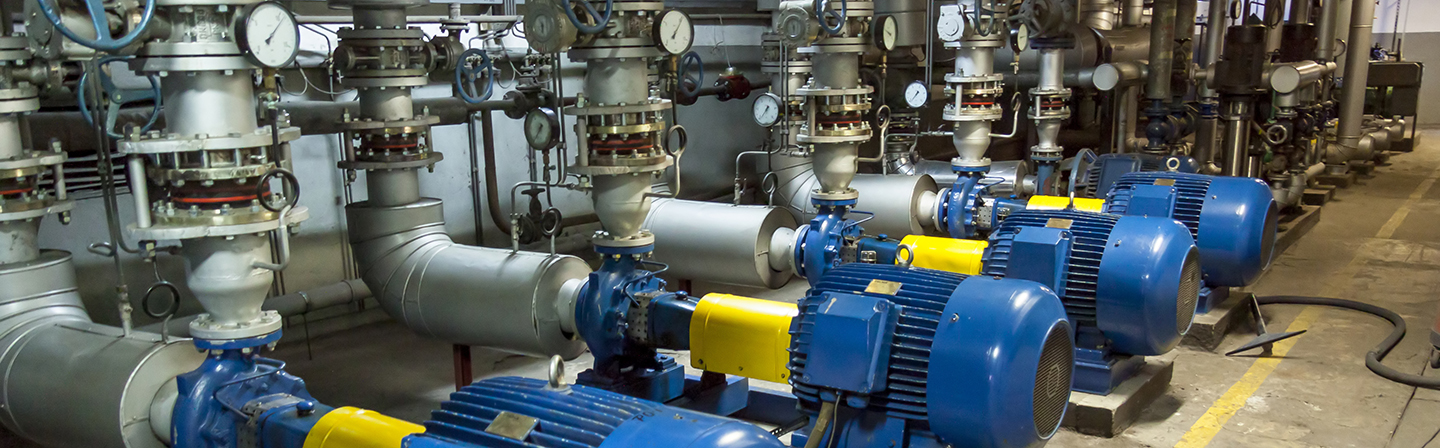

The central question in the field of condition monitoring is the vibration prognosis and analysis of rotating drives. In particular, the working group has many years of experience in the field of torsional monitoring of rotating machines, especially in the case of power plant generator shafts.