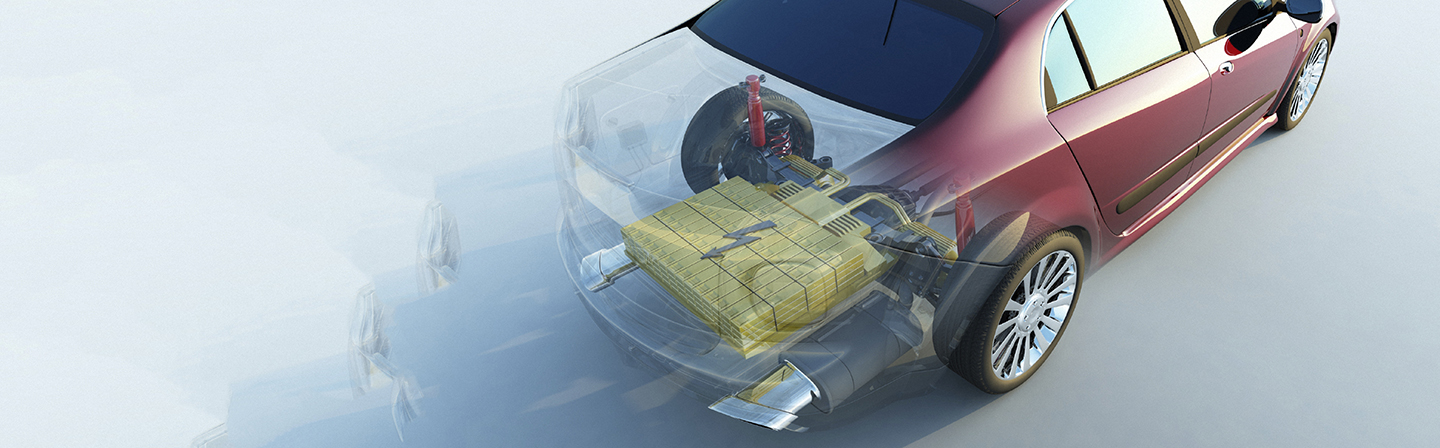

Modern lithium-ion batteries are ubiquitous electrochemical energy storage devices. Advancing aspects like capacity, power density, life-time, safety and costs is essential, in particular for the automotive industry. Additionally, the ramping-up of new competitive gigafactories for cell productions requires optimized and well-controlled production processes.

With our Battery and Electrochemistry Simulation Tool BEST we provide the possibility to predict cell properties by performing physics-based computations on virtual copies of real devices. Our multiscale approach allows testing and optimizing designs on microscopic electrode and macroscopic cell scale, including advanced features such as thermal coupling, degradation or virtual electrochemical impedance spectroscopy.

Beyond the electrochemical cell simulations, we develop simulation models and tools to describe production processes e.g. for electrolyte filling with our software FLUID or electrode drying.

Applications

- Cell and module design evaluation: ABBA-VEEB, TopBat, structur.e

- Estimation of degradation and lifetime: DEFACTO, MULTIBAT, structur.e

- Production process optimization: Cell-Fi, DEFACTO