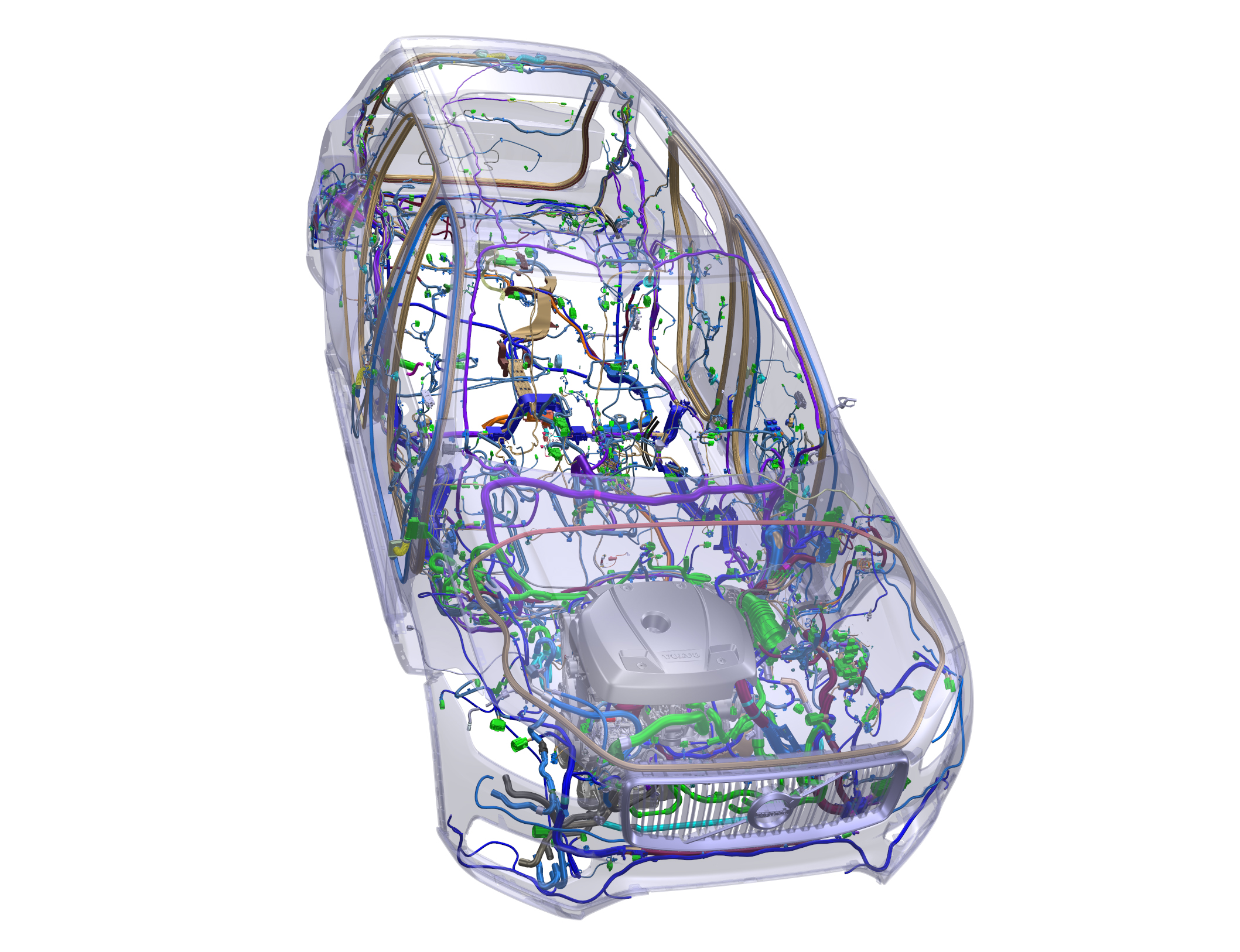

In times of digitalization, companies rely on modern methods of data analysis and machine learning also in product development. Well-known software tools (for CAD and CAE) are thus further developed and expanded. However, virtual testing of product properties requires high-quality material data in sufficiently large amounts. This includes, among other things, the mechanical properties of individual - but also combined - material states and components as well as information on their manufacturing.

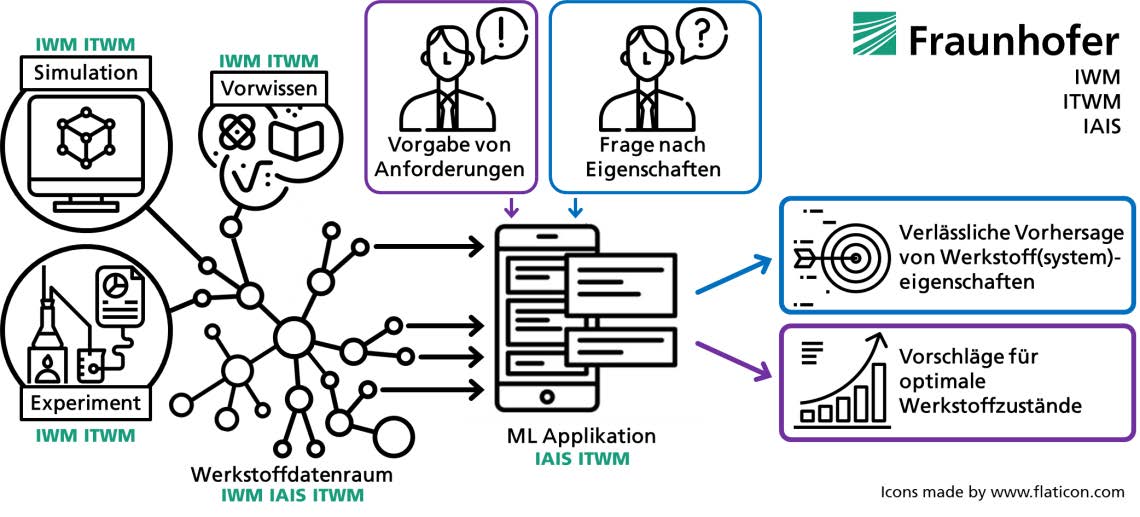

In the Fraunhofer UrWerk project, we are collaborating with two other Fraunhofer Institutes (IWM and IAIS) to develop data spaces that clearly map the history of materials and their interactions in complex material systems in the form of graphs and enable the coupling of analysis tools. These data spaces are adapted to the specific needs of each company and thus offer easy access to material data.