Gaskets are sensitive components. If a damaged gasket for example is integrated in a compressor the risk of malfunction or breakdown is high. Those damaged components are returned to the subcontractor immediately, in worst case the complete charge will be send back.

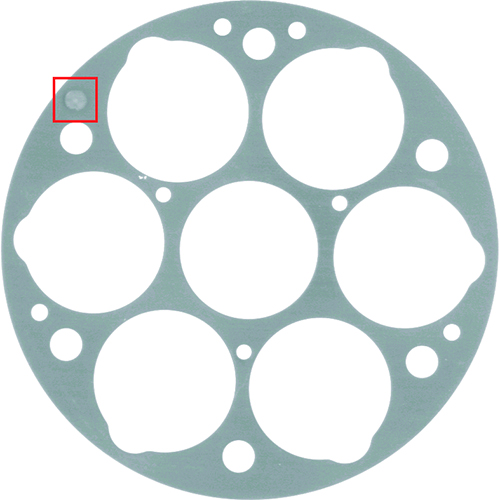

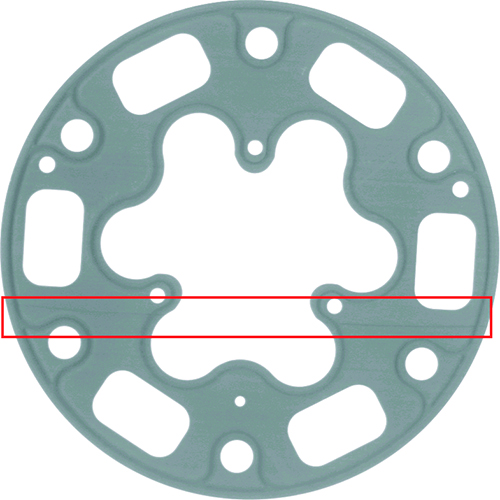

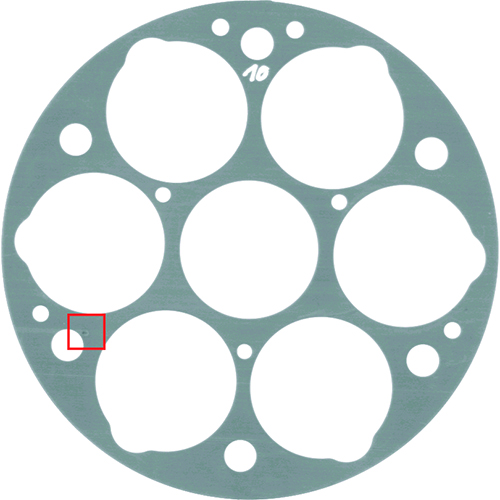

There are different surface defects, on the one hand defects in the feedstock, e.g. bubbles or impurity, on the other hand defects which results from the blanking process, e.g. dents or scratches. Other defects are colour and glue spots as well as geometrical defects, i.e. the punched components differ from their design form. The control of gaskets is strongly essential, but in manual control it is fault-prone and time-consuming.