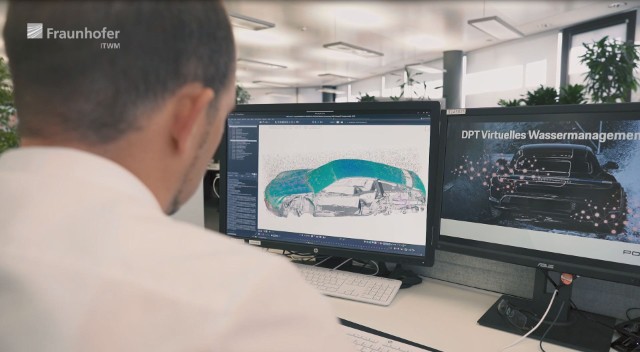

MESHFREE is an innovative software tool in fluid and continuum mechanics developed in cooperation with Fraunhofer SCAI. It combines the expertise in meshfree simulations and scientific computations of the two institutes.

Universal Model for Fluids and Solids

MESHFREE uses a general material model, which allows to simulate complex materials (non-Newtonian fluids, foams or viscoelastic materials) with the same numerical method. The medium does not need to be declared as fluid or solid a priori to choose an appropriate numerical solver. Instead, only material properties such as viscosity or shear modulus are required to predict the material behavior.

Faster Results with MESHFREE

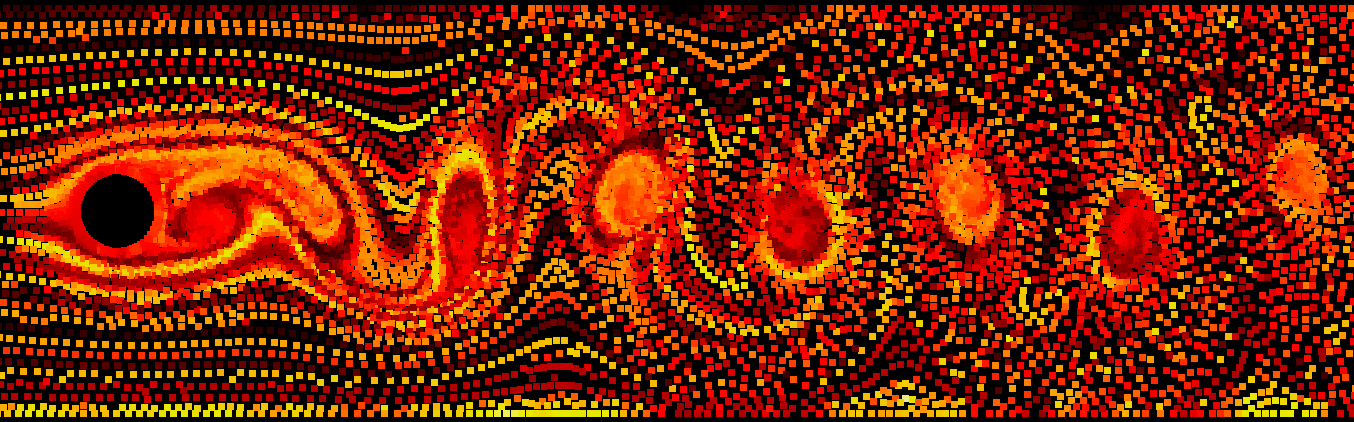

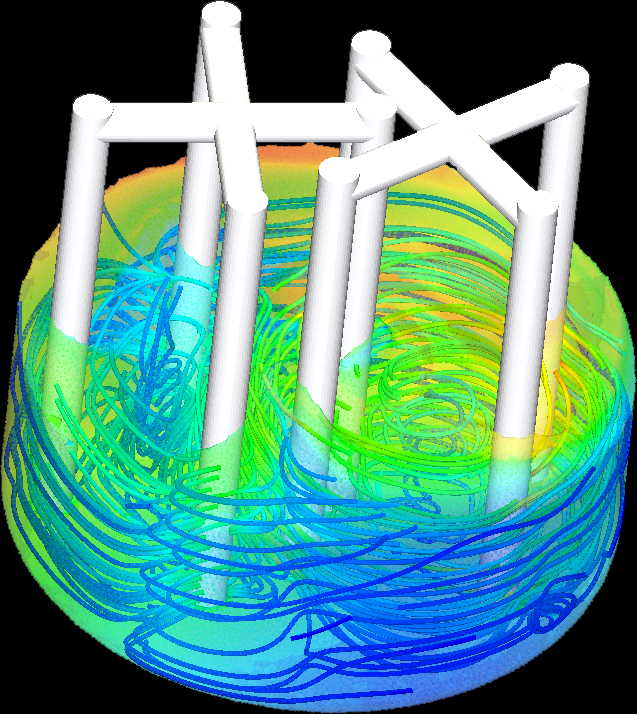

The software MESHFREE combines the Finite Pointset Method (FPM) for solving the conservation equations of mass, momentum and energy with efficient algorithms for solving linear systems of equations. The underlying method is based on a cloud of numerical points without explicit neighborhood information of a mesh, so the need for costly meshing and re-meshing disappears.

The geometry can be exported directly from CAD tools and used for the simulation. Due to the complete absence of a volume mesh, MESHFREE is highly flexible regarding the discretisation of the computational domain in highly dynamic processes, such as flows with free surfaces or fast moving geometry elements.