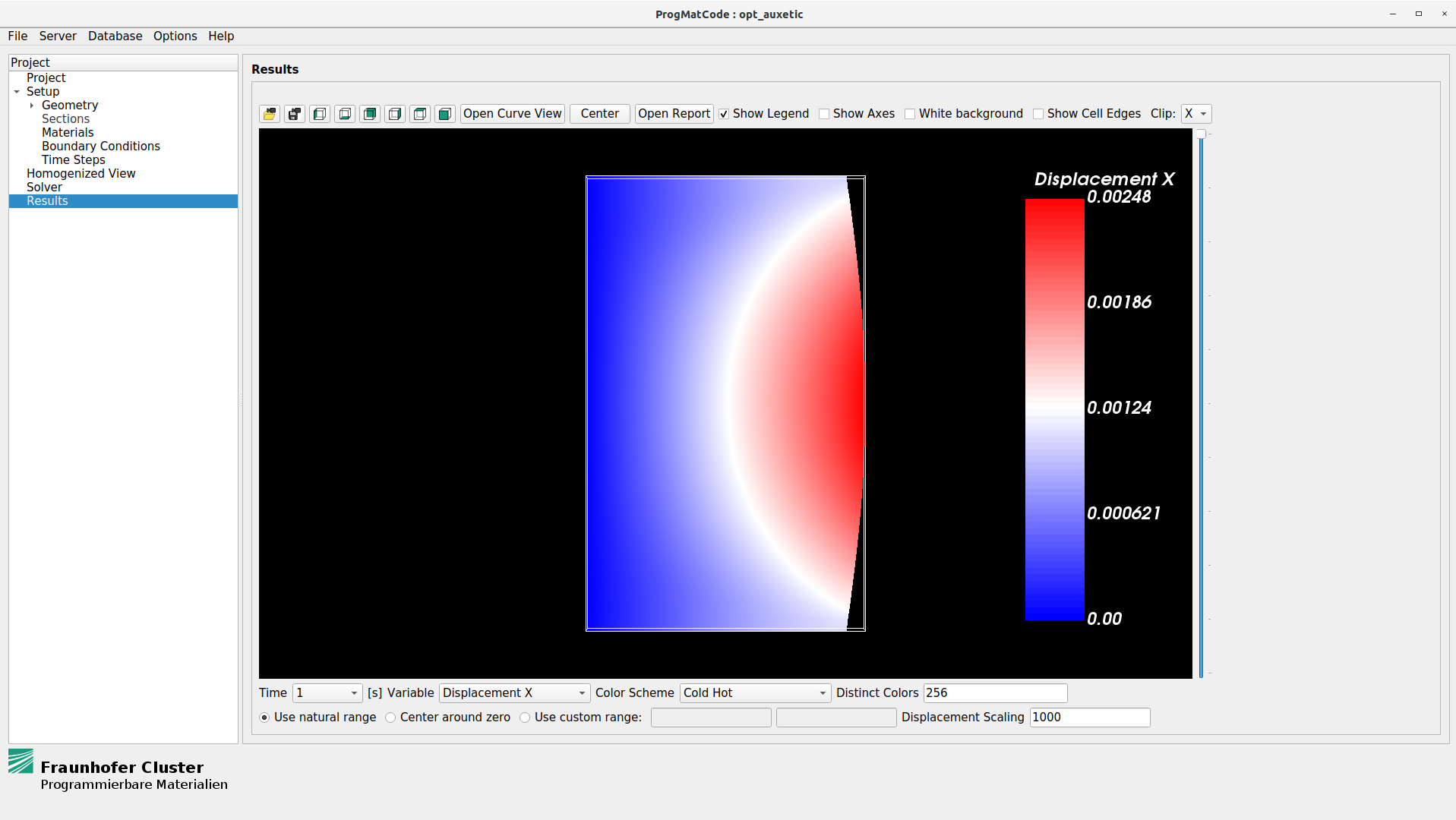

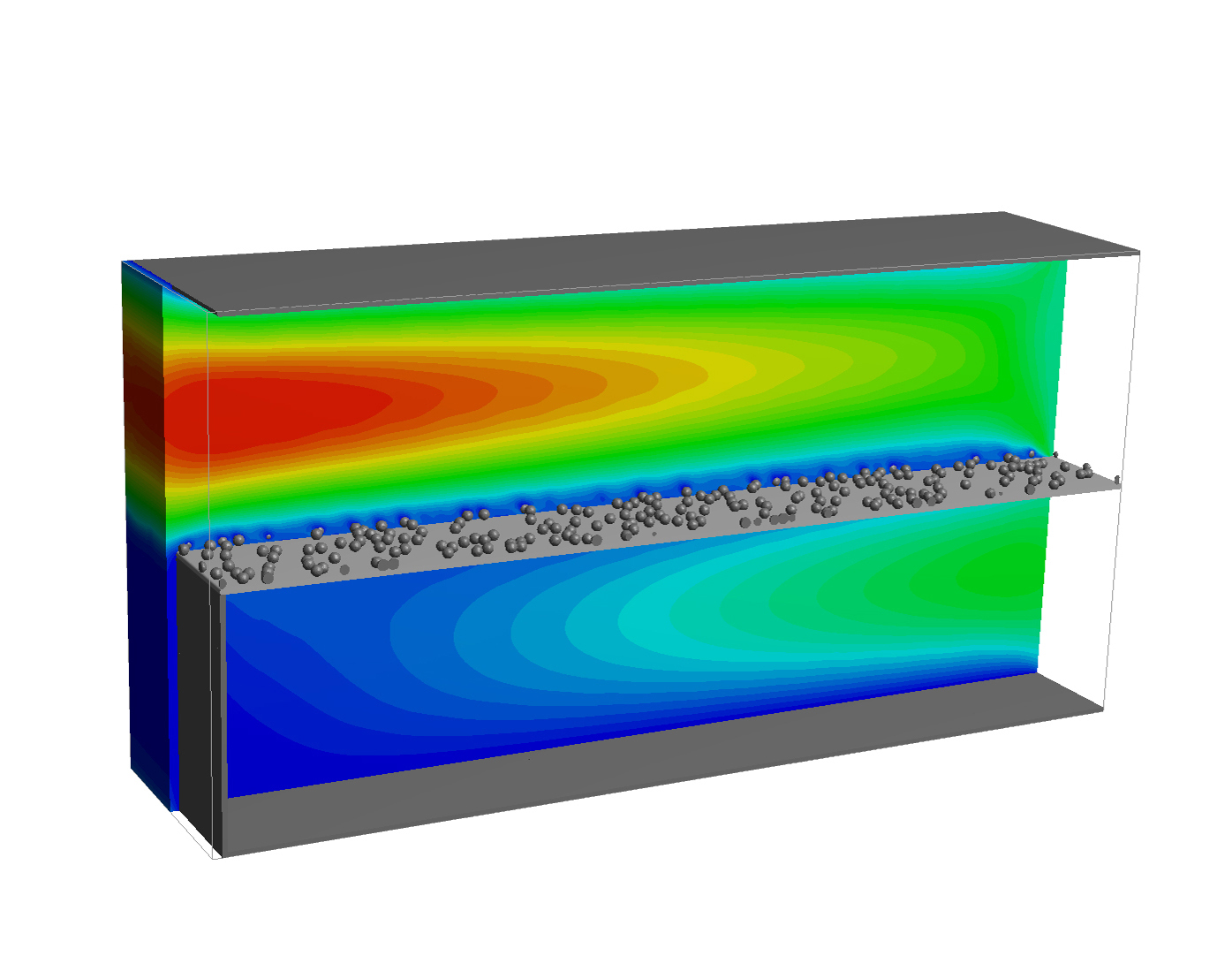

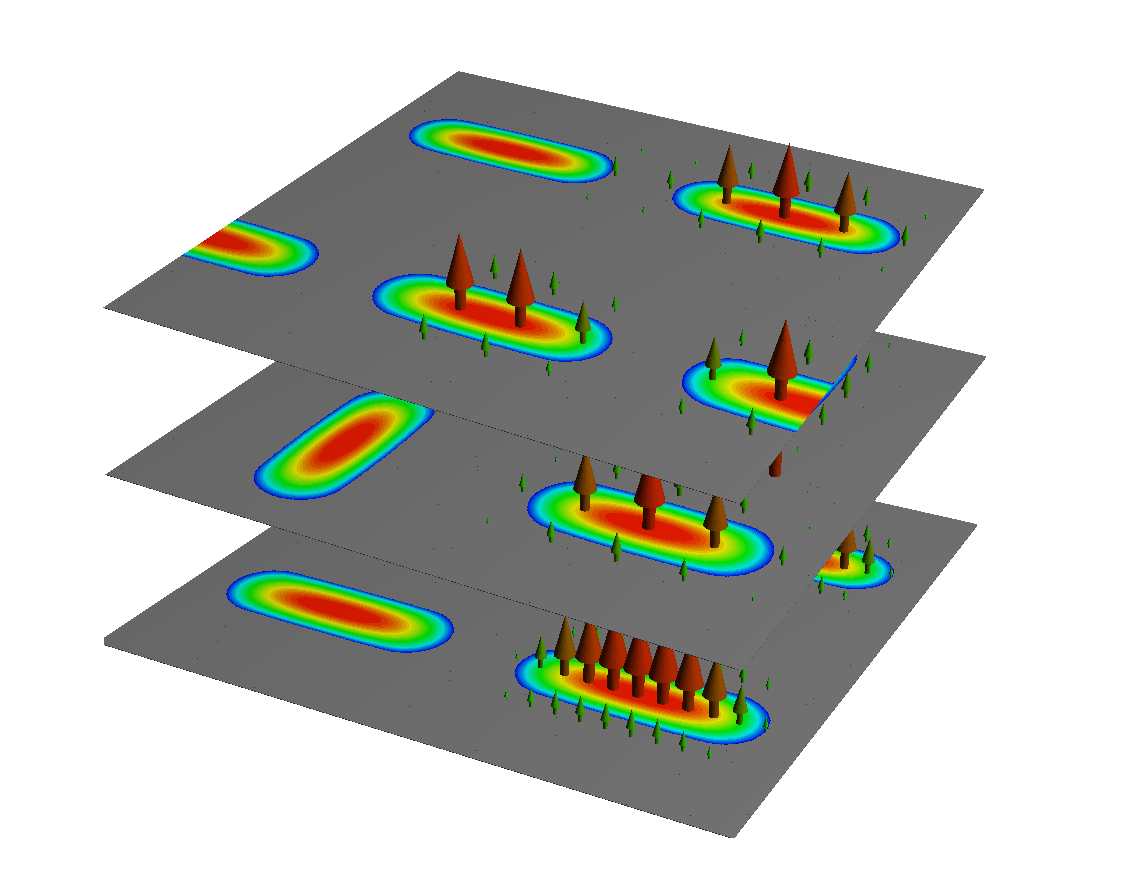

Giving materials new functionalities? We are finding ways to do that in various projects in the field of »Programmable Materials«. What we find is that not only the basic material itself is changed, but also its internal structures, mechanics or even transport.

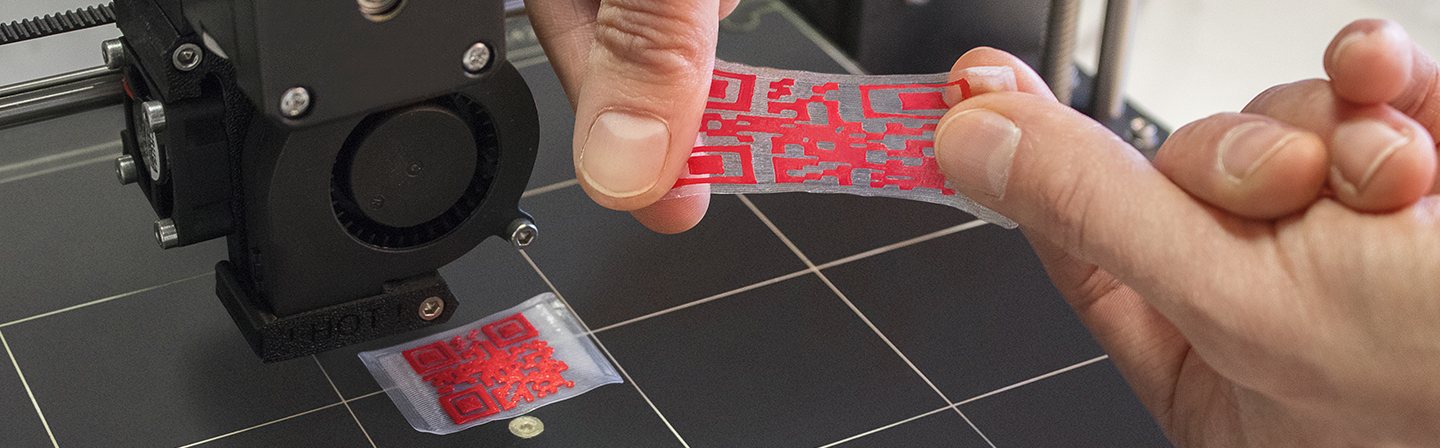

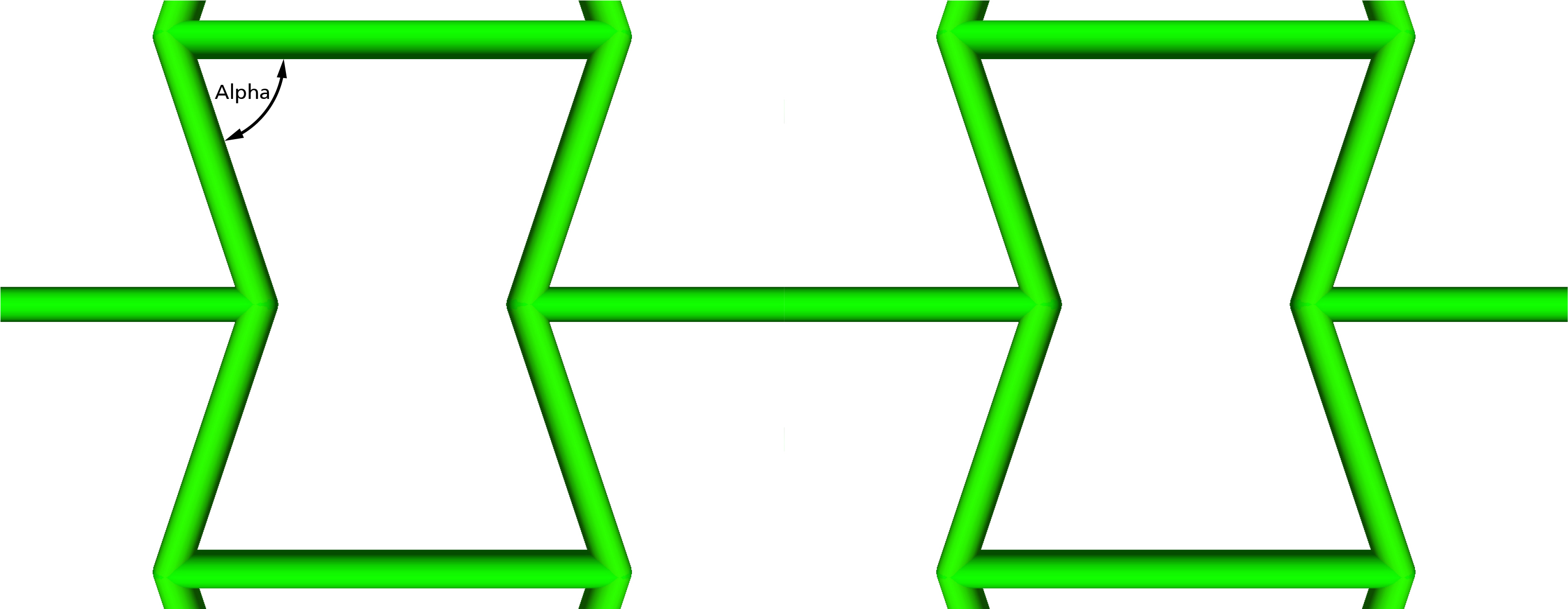

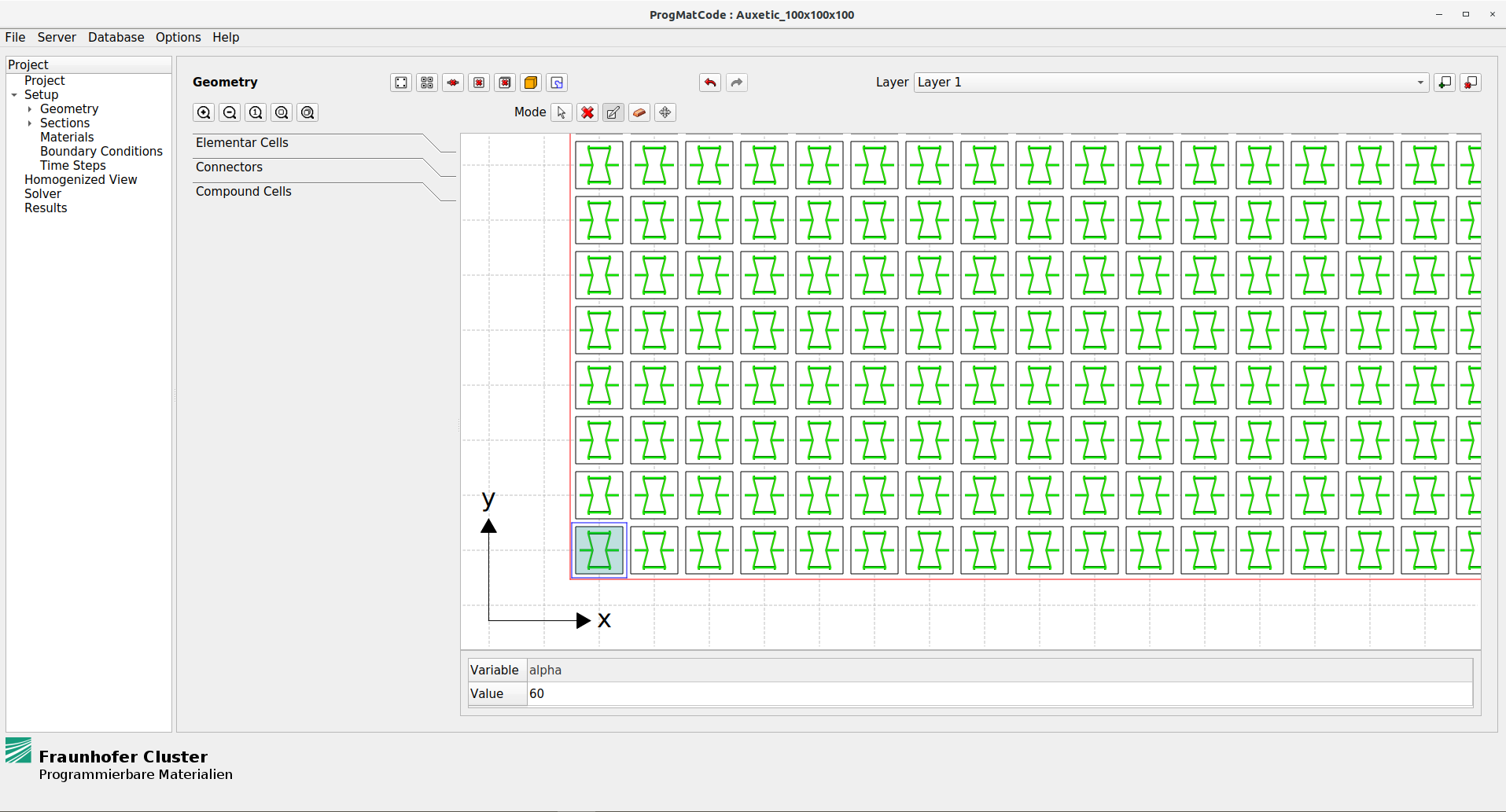

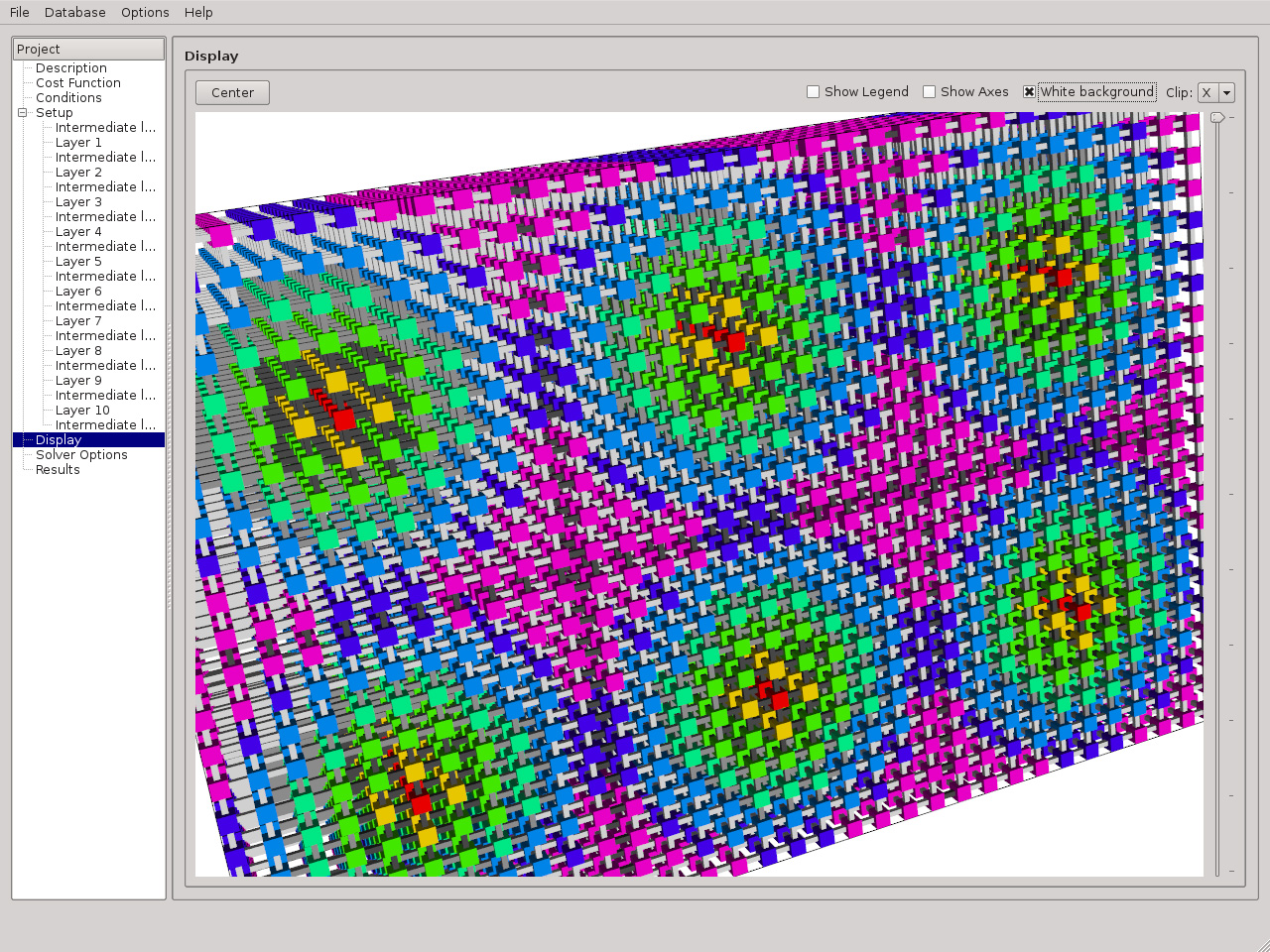

New manufacturing methods make it possible to specifically produce structures in the micrometer range. Additive processes such as 3D printing are used for this purpose. An engineer uses these methods not only to design the outer shape, but also to target the internal microstructures to give certain properties to a component. In cooperation with other Fraunhofer Institutes, we go one step further and define multiple states for such microstructures and apply external stimuli to switch between them.