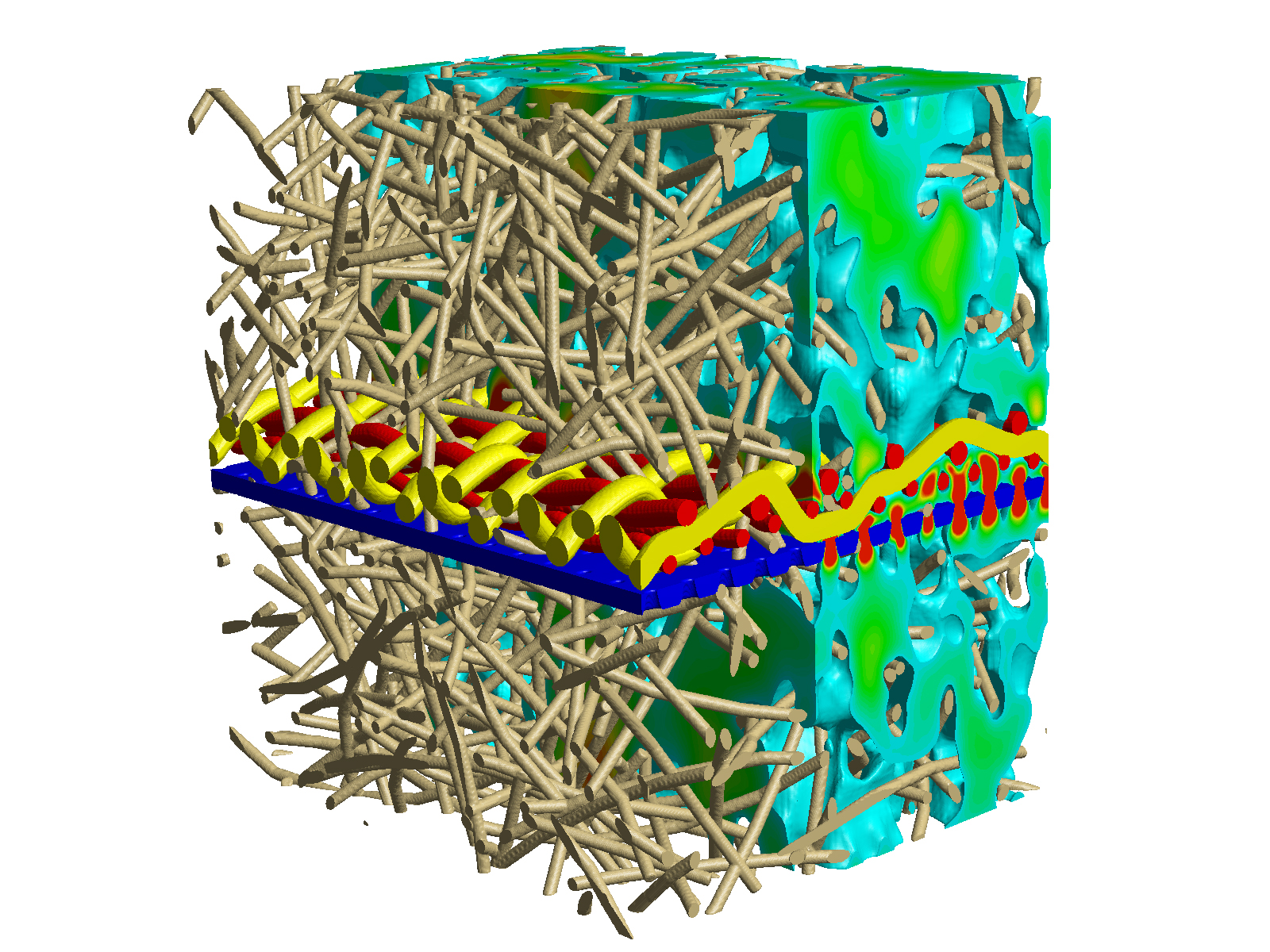

The mechanical dewatering is a complex fluid dynamical process which is influenced by effects ranging from the micro-scale to the macro-scale. These dimensions refer to textile structures up to press rollers with 1 m diameter. Accordingly, the analysis is also done by a multi-scale simulation.

Multi-scale Simulation of Paper Machine Clothings

The starting point of the micro-scale analysis is a flow simulation by means of the GeoDict software developed at the Fraunhofer ITWM. In the pursued approach, GeoDict provides the capability of analysing both real and virtually created press felt structures.

By means of the software a multitude of machine parameters can be combined on the macro scale with the data acquired from the micro-simulation. In addition to the dewatering performance, this simulation also provides better insight into the dynamics of mechanical dewatering in order to support new developments. Along with the analysis of existing press felts and paper machines, the simulation also provides the capability of testing innovations in the early stage of development. In doing so, the artificial generation of virtual and innovative structures with the corresponding dewatering simulation guarantees a technological advantage.