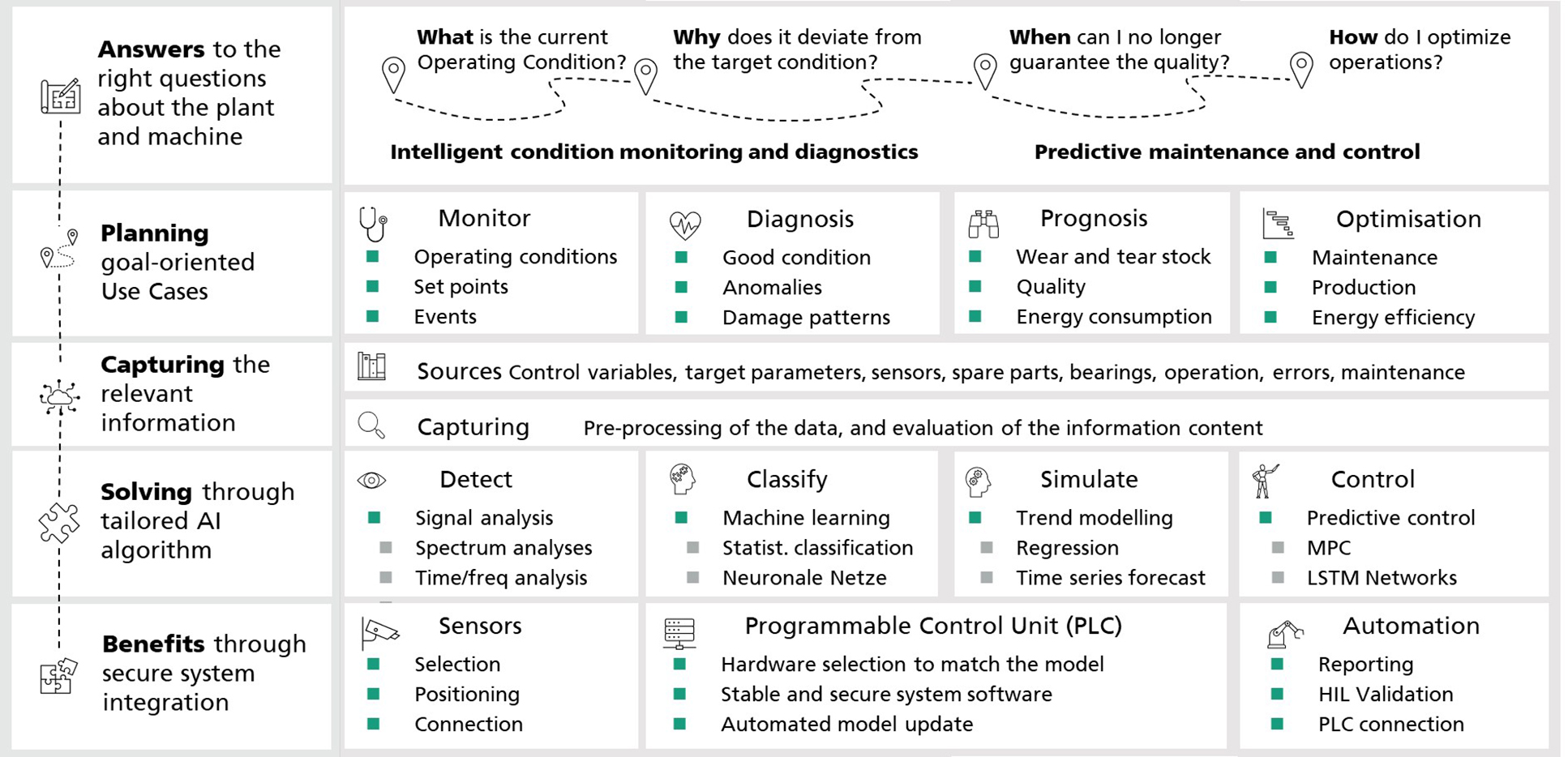

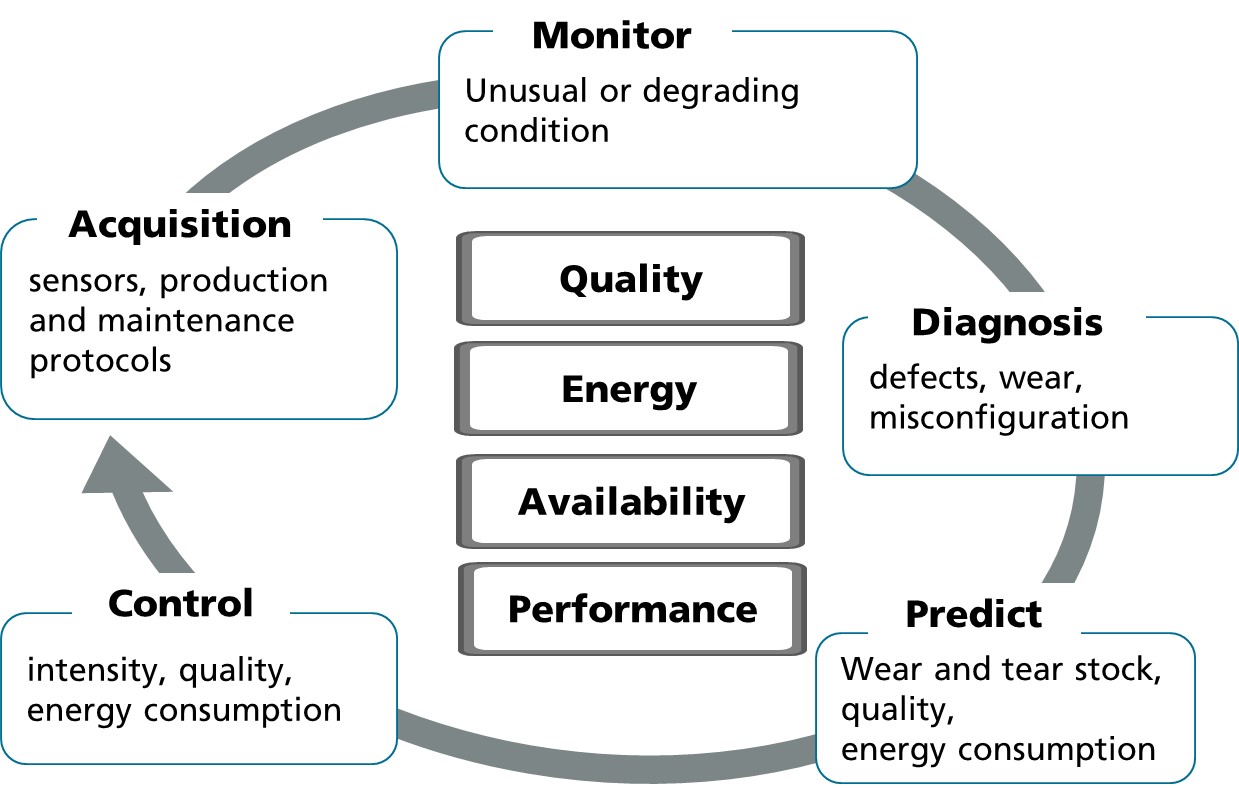

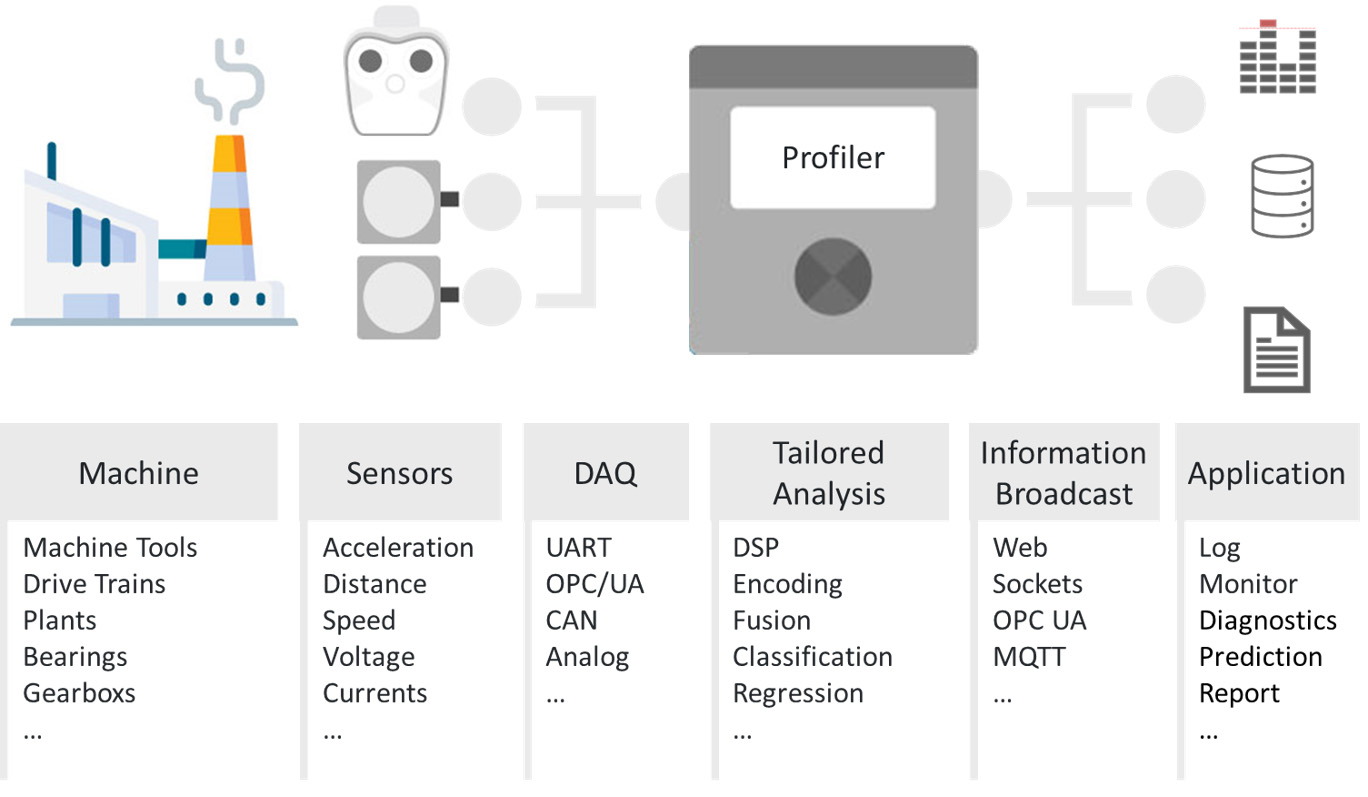

With our research and project experience, we develop customized solutions for predictive and condition-based monitoring of individual special purpose machines and test benches in maintenance, their production and quality assurance.

Our Mission

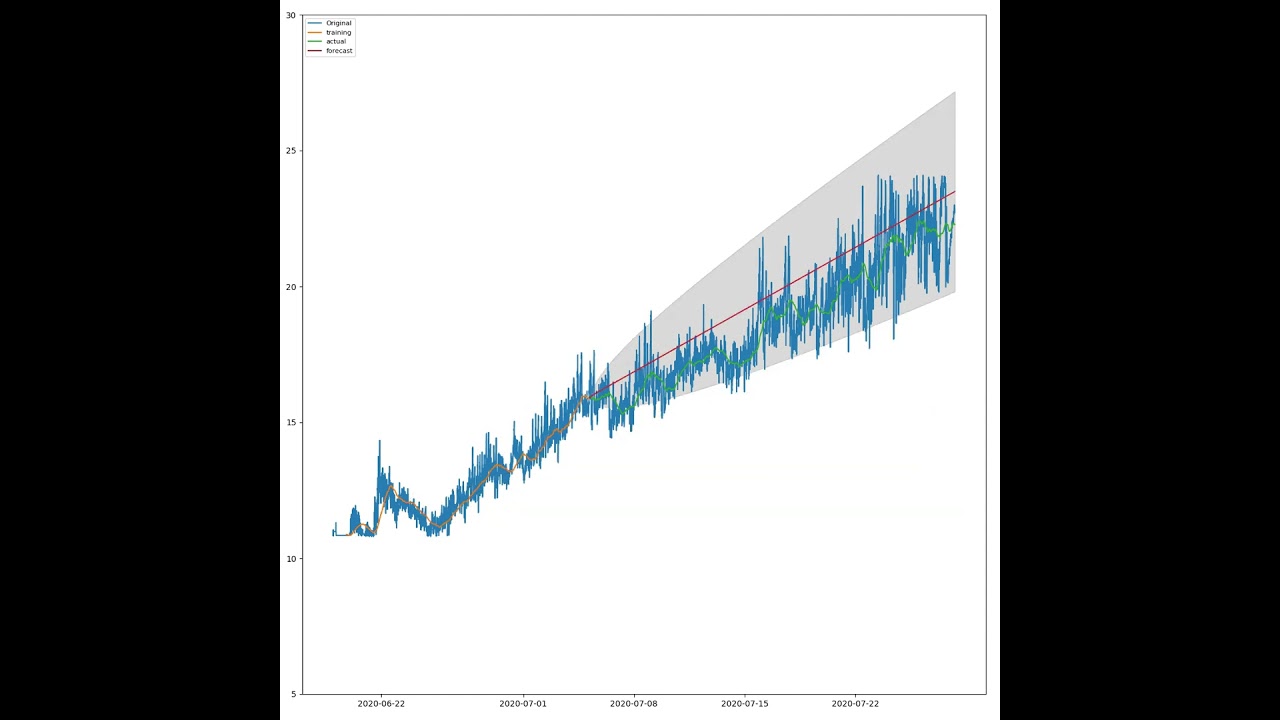

- To make the current wear stock with impact on quality, reliability and energy consumption, measurable and predictable.

- Digitization of inspections to collect key performance indicators (KPIs) and plans in maintenance and production in an automated way.

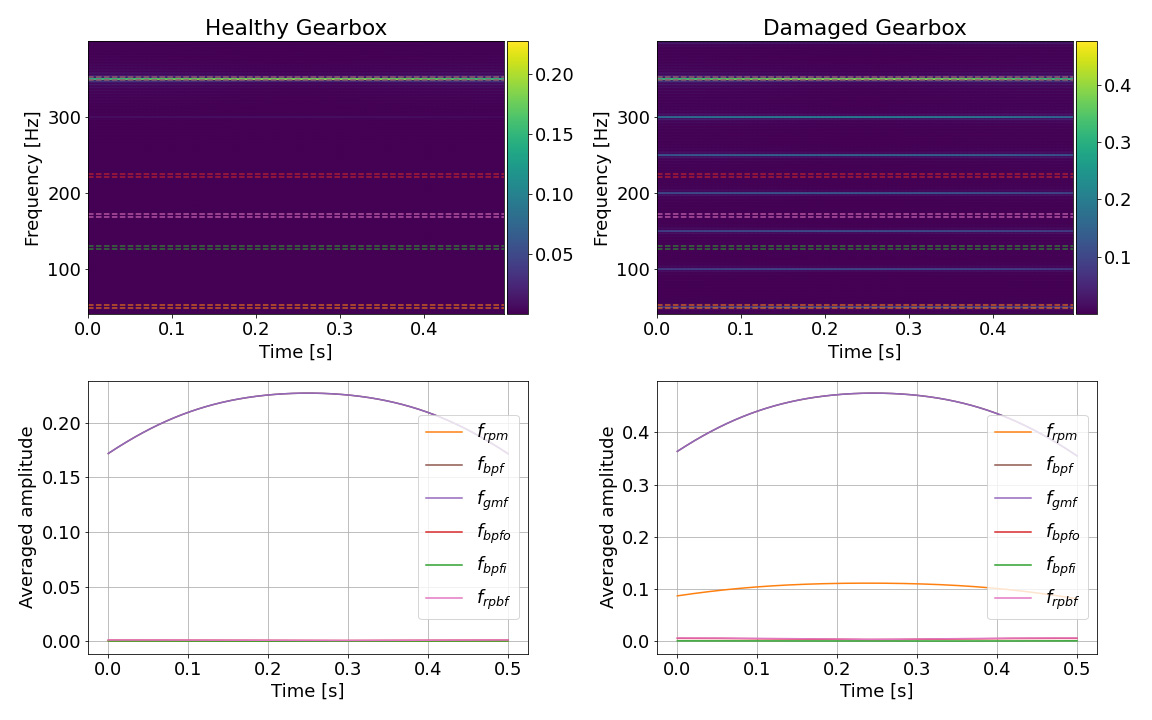

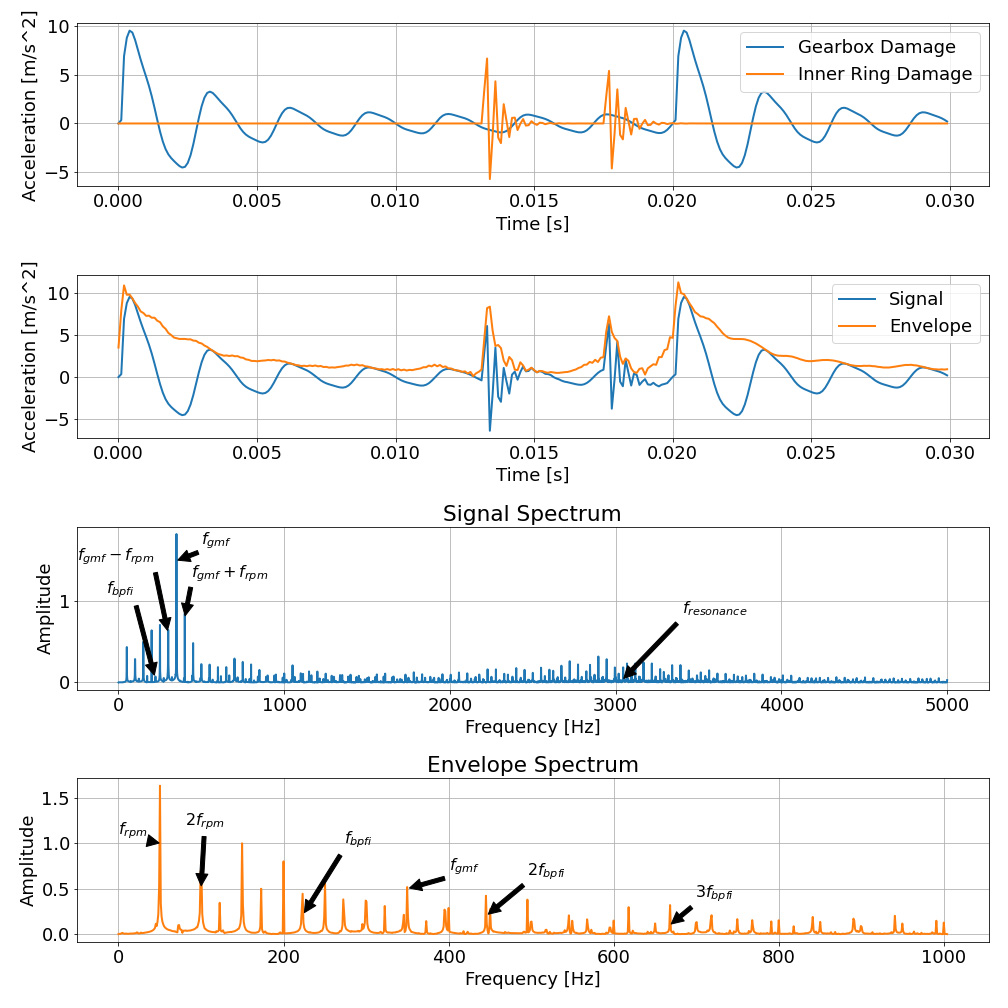

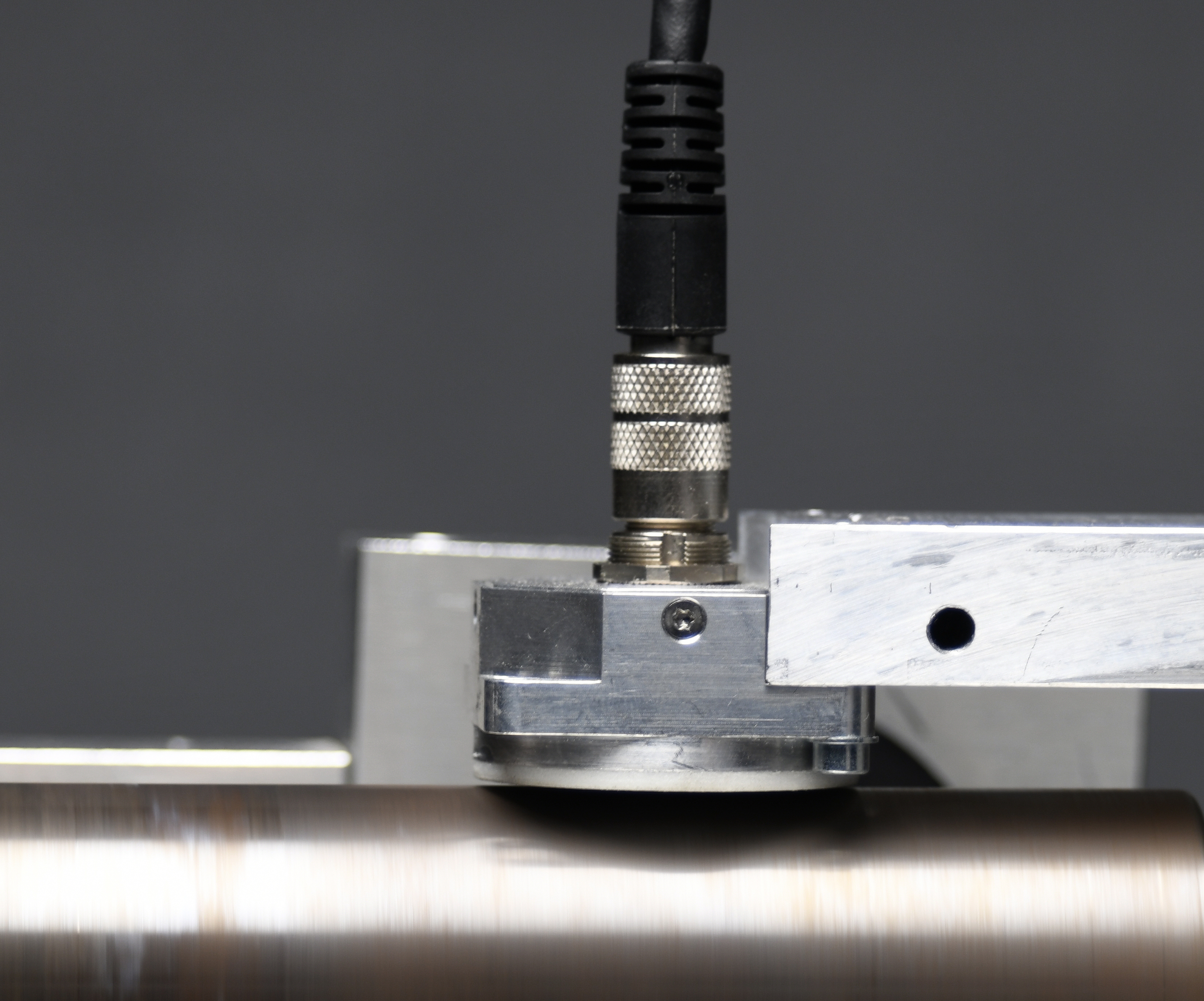

- Monitoring of multiple assemblies with just a few sensors, e.g. on the drive train: motor, inverter, bearing, gearbox, shaft or on machine tools: spindle, tool suspension, workpiece suspension.

- Multisensory signal analysis with intelligent algorithms that take into account setup and operating states of the system.

- Incremental model construction to perform TARGET/ACTUAL comparisons of plant states and to clearly diagnose and localize faults.

- Identification of efficient manipulated variables to operate plants more sustainably (wear, quality, throughput, energy consumption, scrap) or more efficiently.