The properties of materials composed of wood fibers like particleboards, oriented strandboards OSB or medium density fiberboards MDF) are primarily affected by the size and orientation of the particles. These boards are produced by compressing lower density boards and exhibit a higher degree of homogeneity, inducing a increased tensile and bending strength.

In particular, medium density fiberboards with thickness of approx. 2 to 6 cm and a density below 650 km/m qualify for the production of furniture and (higher densification provided) for laminate flooring panels.

The Basic for the Fabrication and Virtual Strength Assessment of Light-Weight MDF Boards

To develop boards with lower density, yet comparable strength characteristics, the basics for the fabrication and virtual strength assessment of light-weight MDF boards consisting of layers with aligned fibers similar to plywood or OSB were laid within the framework of an AiF project supported by BMWi, in cooperation with the Fraunhofer Institute for wood research WKI, Braunschweig. The project was co-financed by European Regional Development Fund (ERDF).

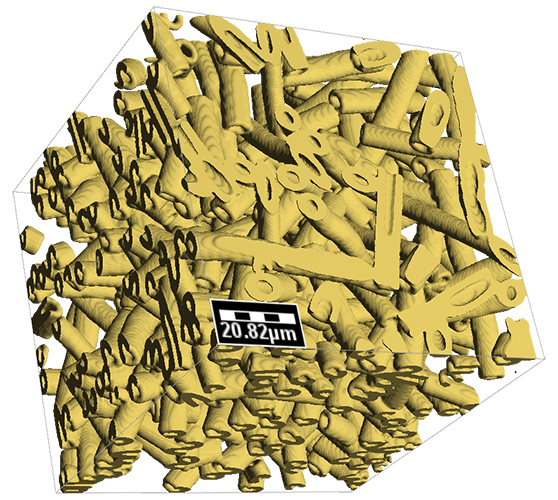

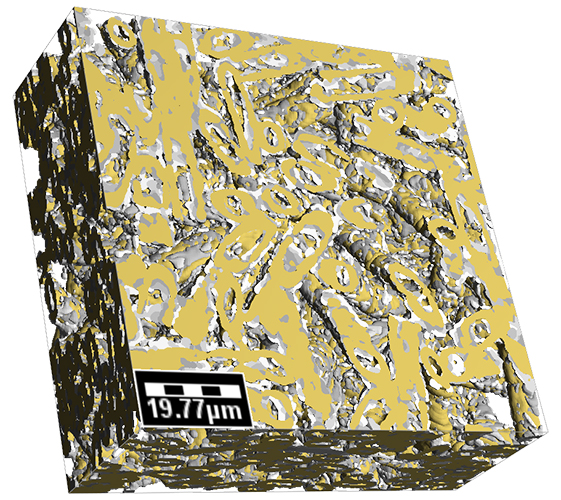

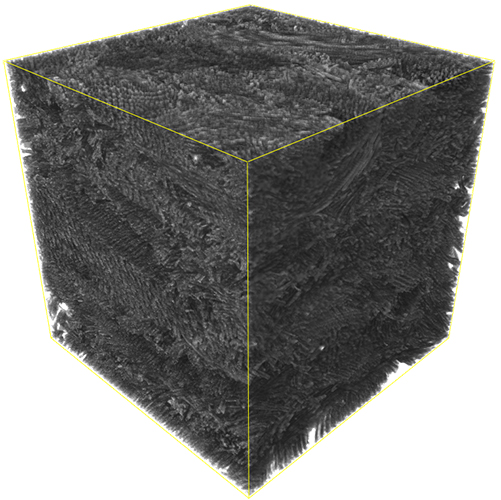

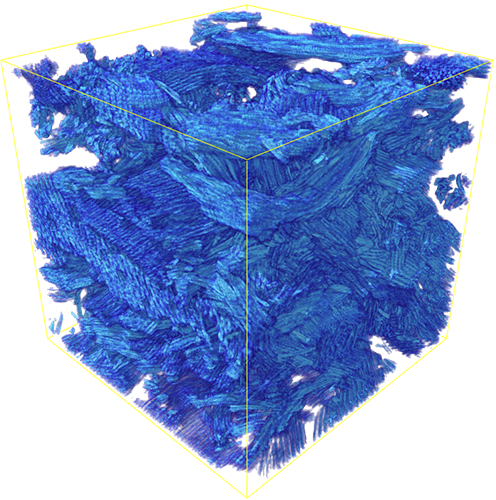

On the basis of micro-computed tomography images (μCT images) virtual wood fiber network models were generated.

Computation of the Deformation with FeelMath

The Software FeelMath developed at ITWM enables the computation of the deformation of the individual wood fibers taking into account mechanical loading on a small section of the fiber board. Treating microstructures with such a high complexity is unequaled globally. Furnishing the generated microstructure model with the mechanical parameters of both wood fibers and glue reproducing enables predicting the experimentally determined strength of the MDF boards accurately.

In contrast to classical experiments the virtual material cycle permits fast design and parameter studies, investigating the effects of changing the fibers’ length or degree of orientation on the mechanical properties of the MDF board. Furthermore, in the project it was possible to characterize fiber bundles and to explain their influence from a mechanical point of view. Consequently, improvements of the production process can be gauged more accurately than by visual inspection.

Project Partner

Fraunhofer Institute for Wodd Research in Braunschweig

Grant

The project is supported by BMWi and by the ERDF funding.