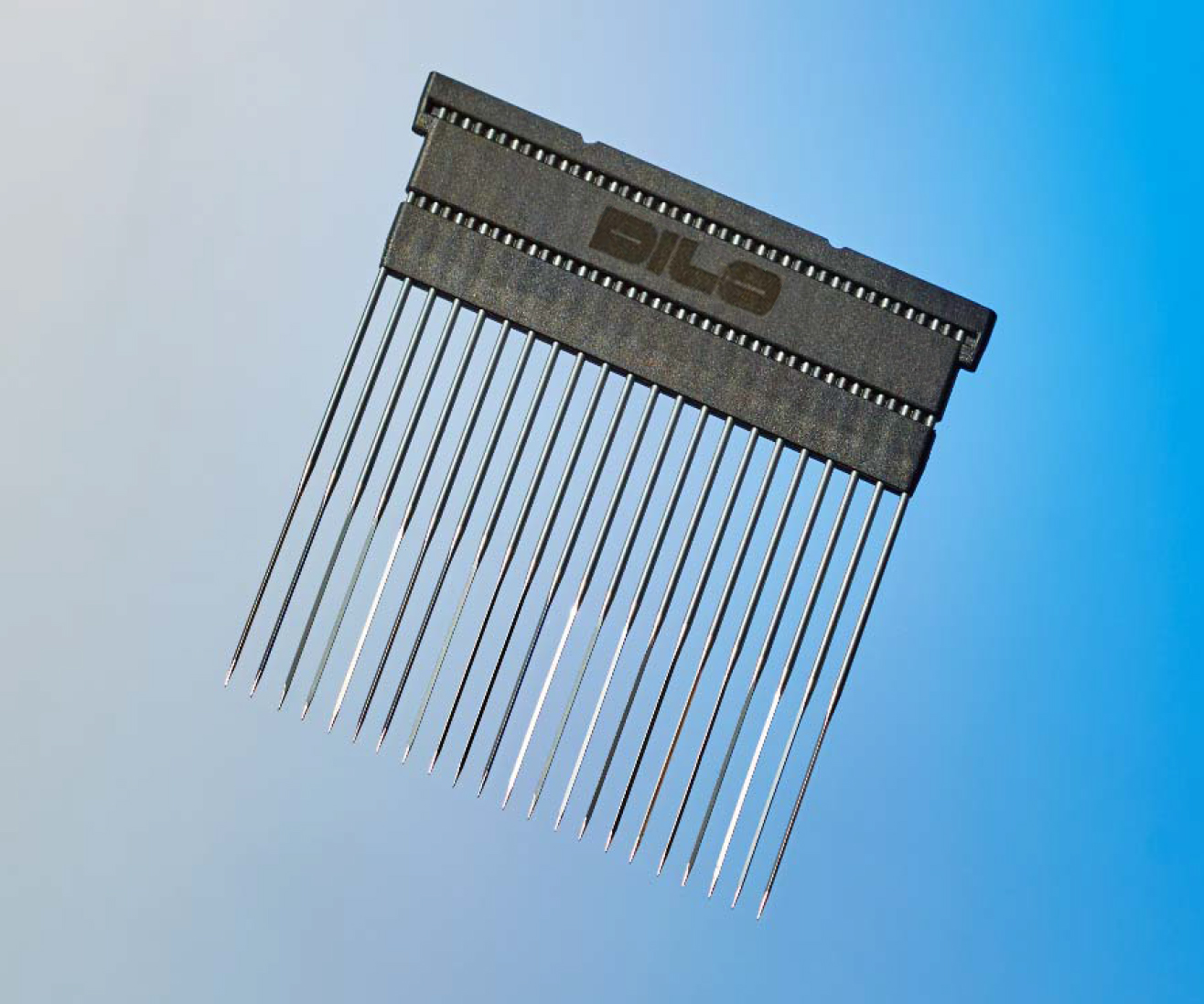

The Dilo Group of Eberbach, Germany develops and produces innovative systems for the nonwoven materials industry. Needle punch systems used for mechanical bonding of nonwoven fabrics play a major role in their business. We assist Dilo in the development of Variopunch, a needle punch technology that will contribute to a more uniform pinhole pattern.

Dilo-Variopunch – Adaptive Needle Punch Technology

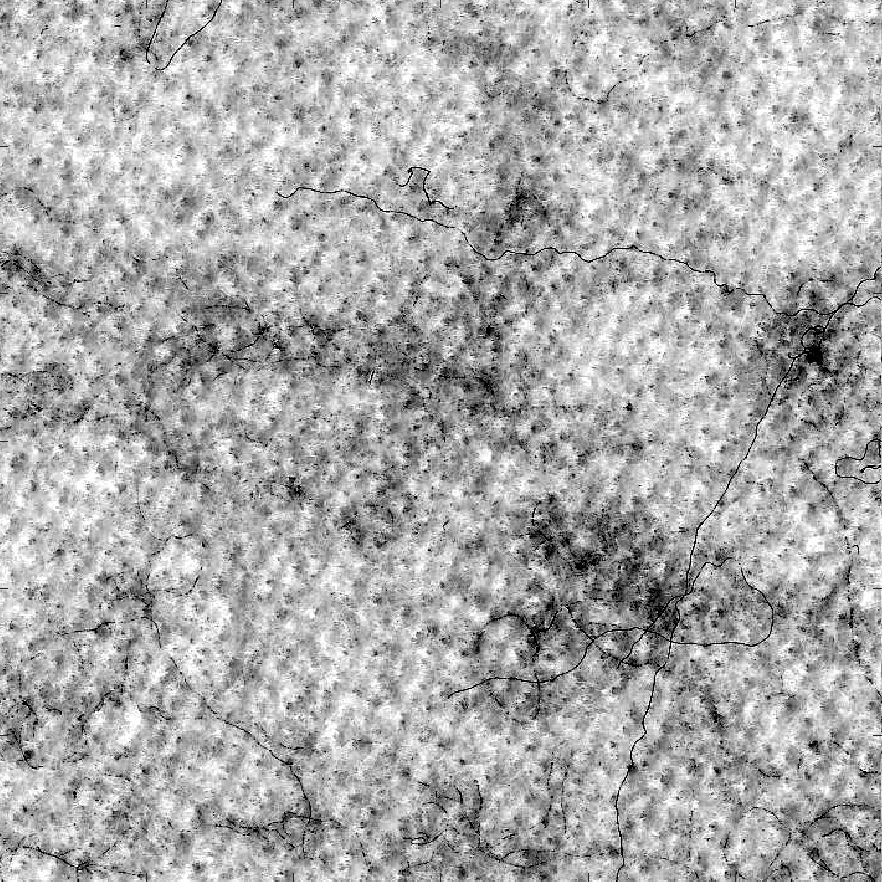

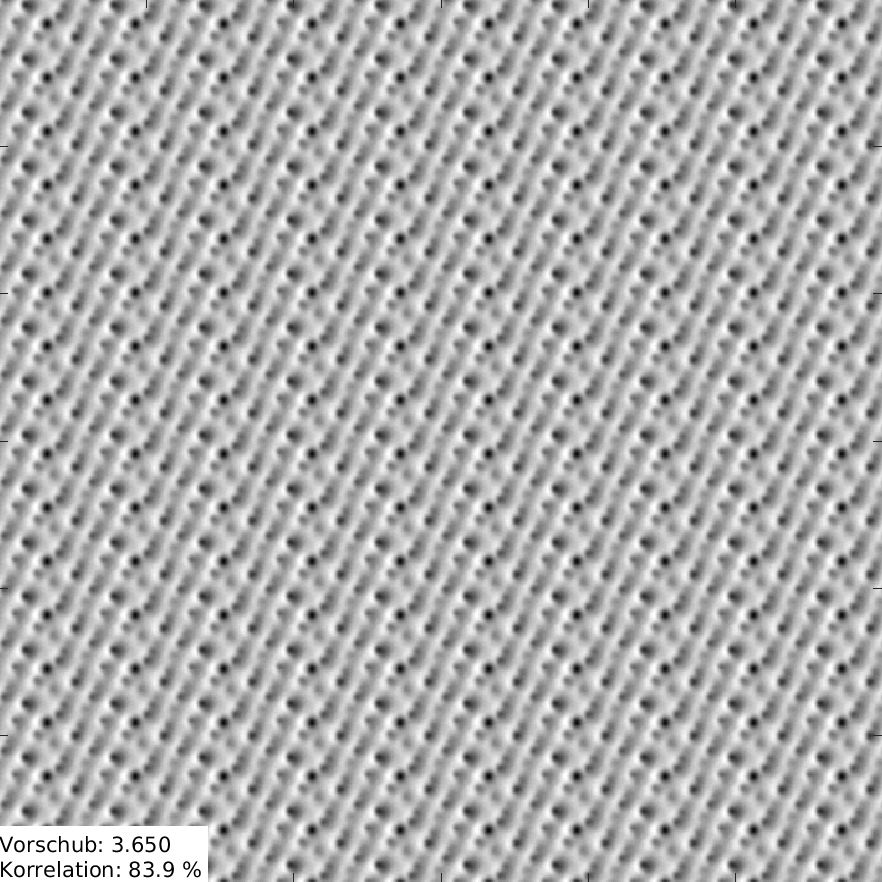

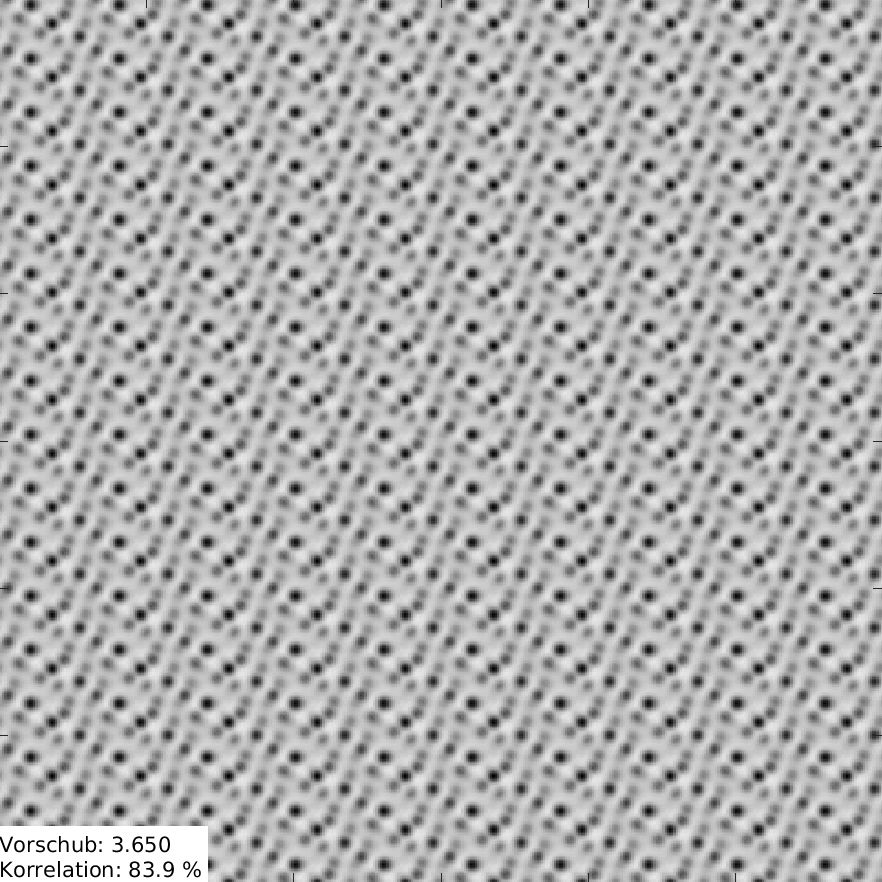

A large number of needles are arranged in a repeating pattern on a needle board. The needle board continuously moves vertically in and out as the nonwoven material is transported underneath. As a result, the individual fibers are locked together giving the fabric strength. Besides strength, the optical impression also plays a crucial role for many applications because the needle punch inevitably leaves a pattern.