The optimization of filter element designs is a challenging task due to increasing requirements concerning the filtration efficiency, dirt holding capacity and service life. In more and more application areas, purely empirical product development based on the testing of real-world prototypes is recognized as very time-consuming and costly.

A simulation supports the developers in this task: It calculates all relevant filter characteristics – such as cleaning performance and service life – and thus allows efficient, cost-effective development.

Modeling and Simulation of Filtration

In order to accelerate the development phase and to assist engineers in finding an optimal design, Fraunhofer ITWM develops the Filter Element Simulation Tool (FiltEST). More than a decade of expertise and experience in modeling and simulation of filtration processes are combined in this simulation software.

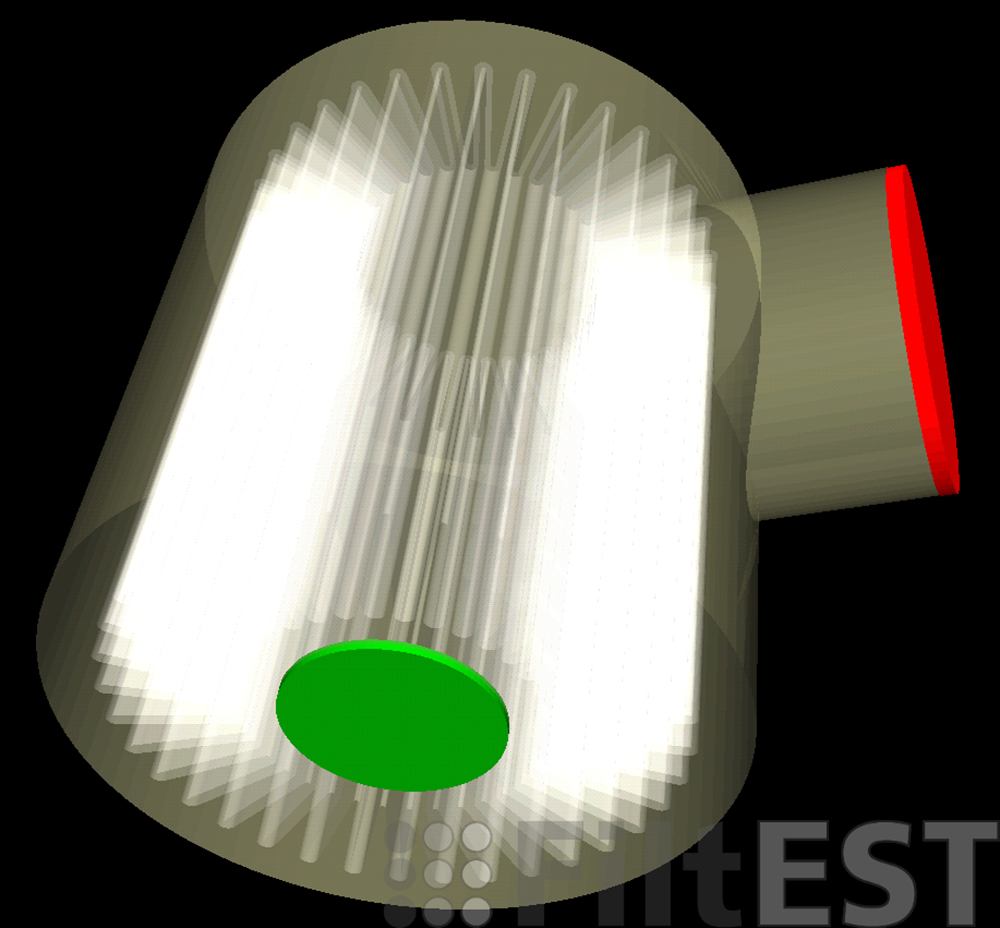

FiltEST uses specialized models and numerical methods for the

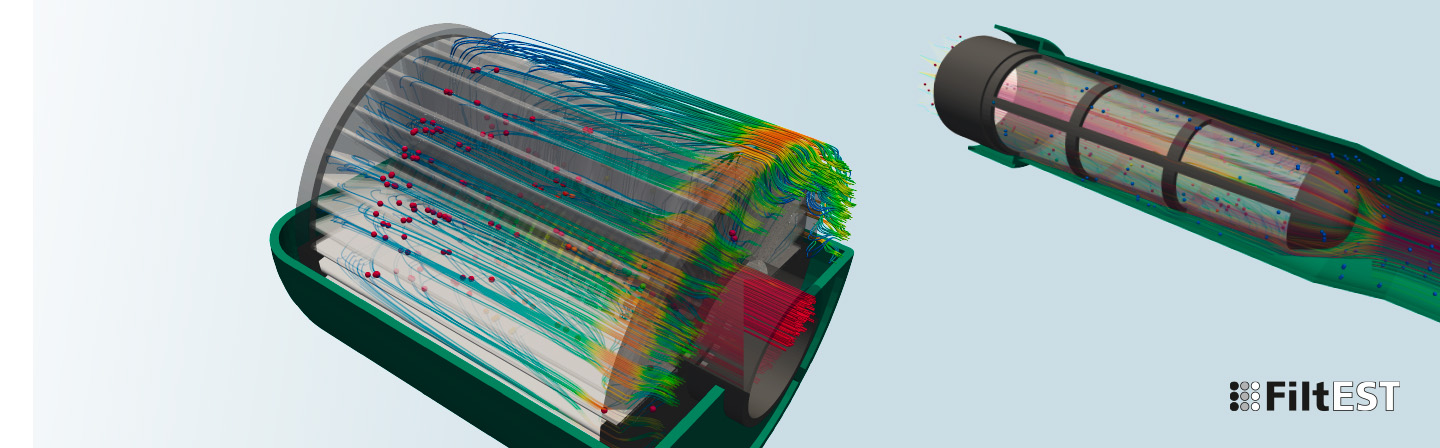

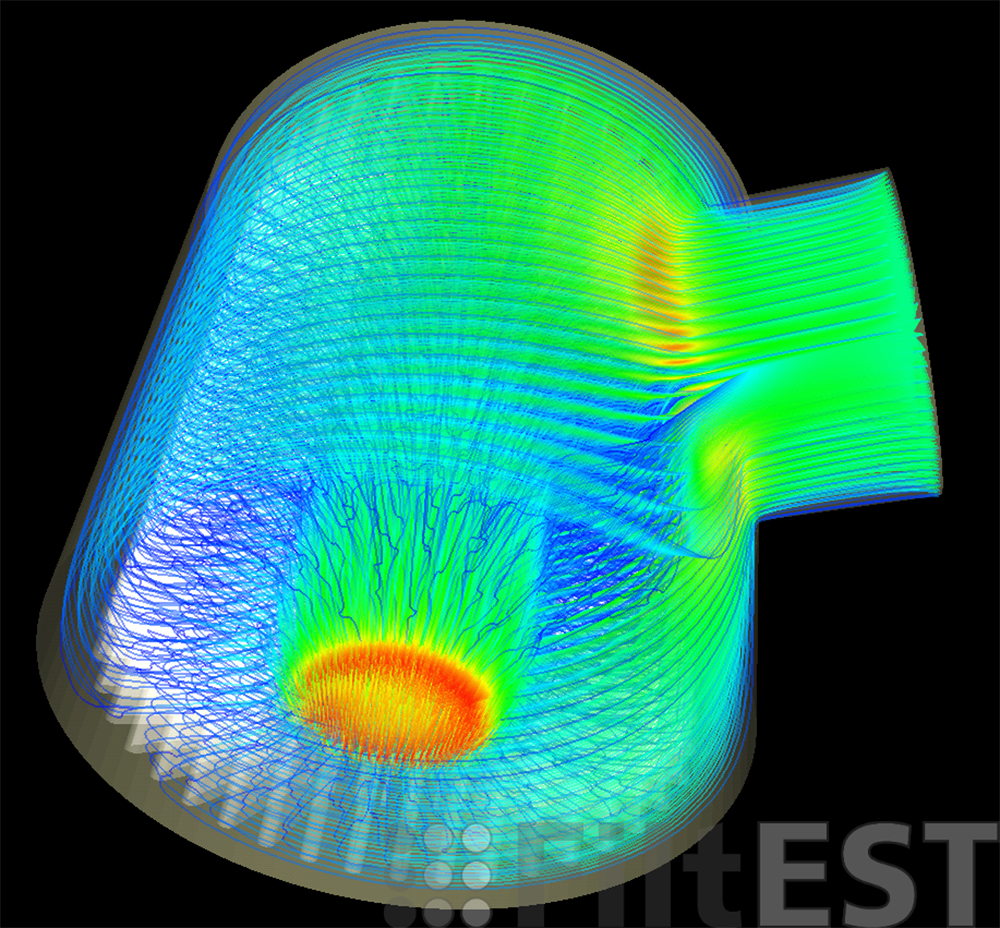

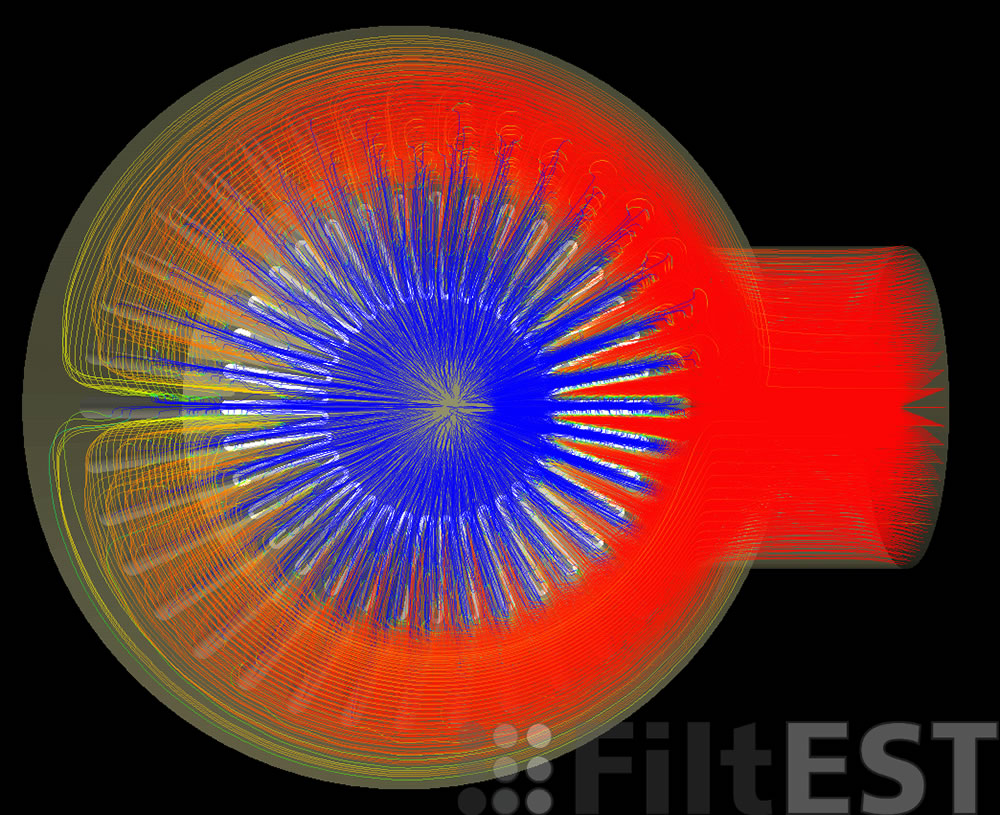

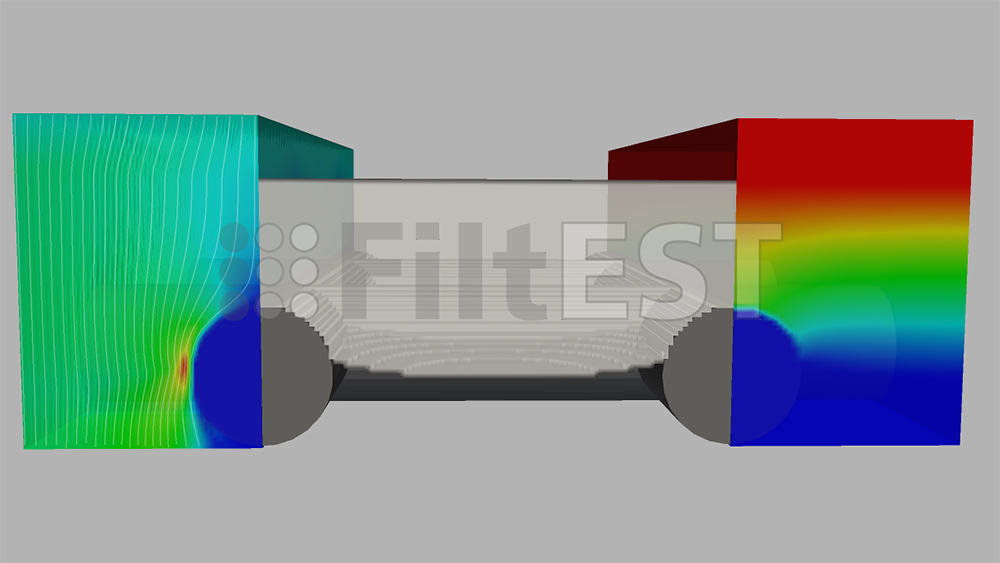

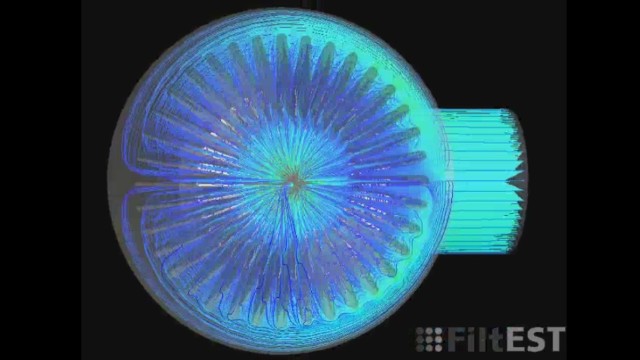

- simulation of the fluid flow through the housing and the filtering media

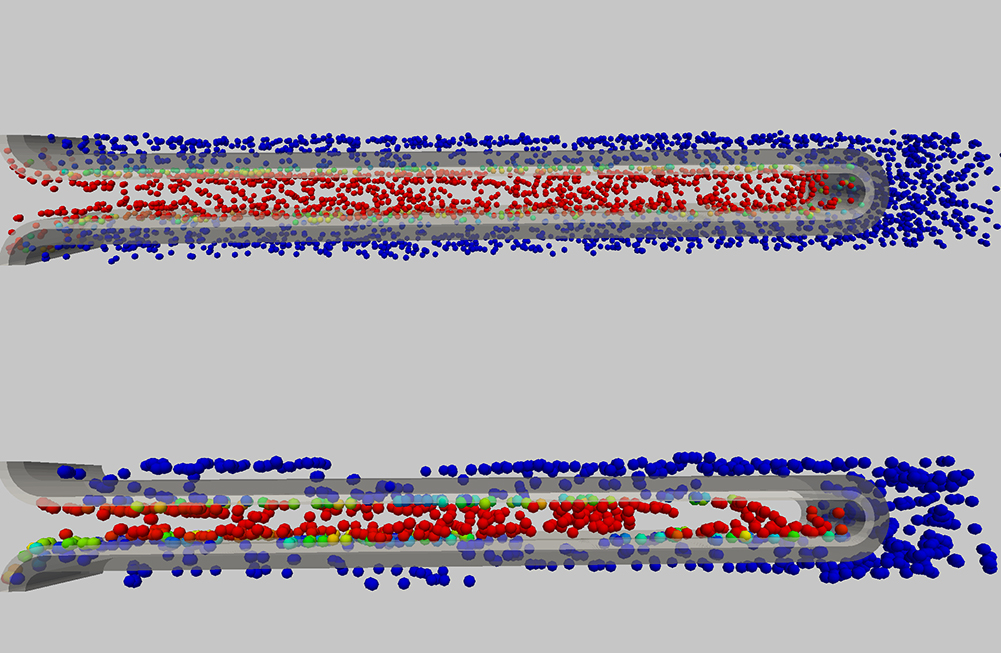

- simulation of the transport of particles and their deposition

- computation of the evolution of the permeability distribution and the total differential pressure caused by the loading