In many applications, it is important to understand how the micro structures influence physical properties of cellular materials as for instance permeability, acoustic or thermal insulation, stiffness. Models matching the geometric features of the micro structures are a powerful tool to investigate this link.

Modelling of Microstructures: Foams

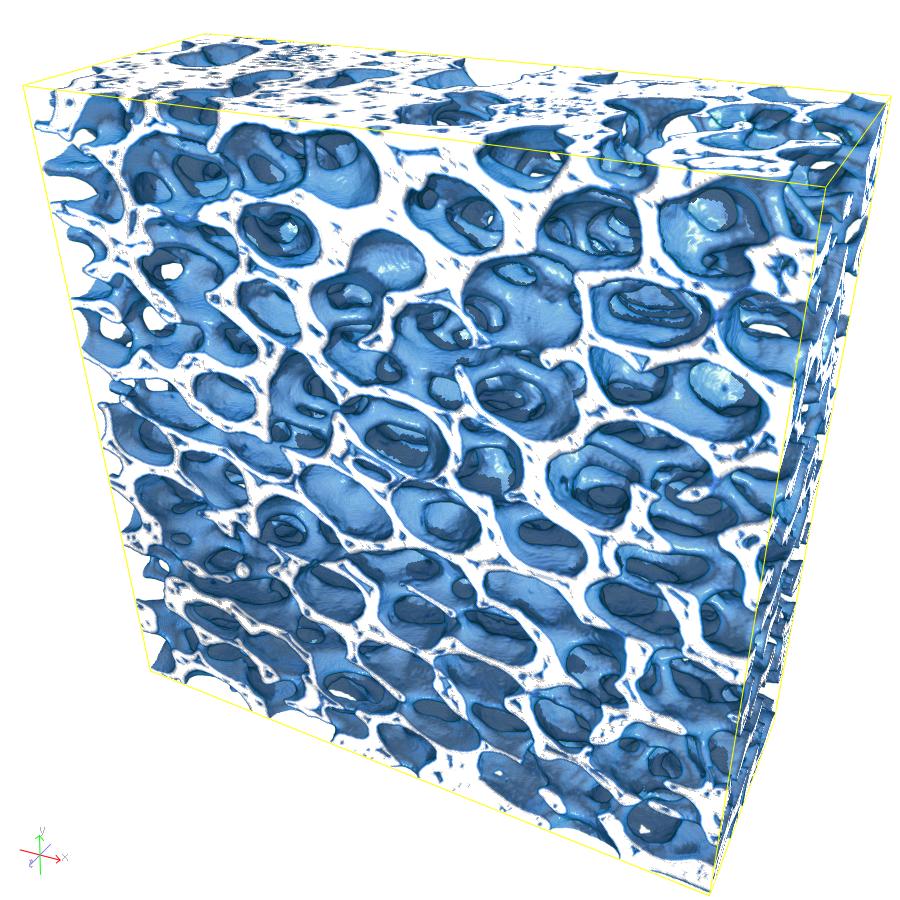

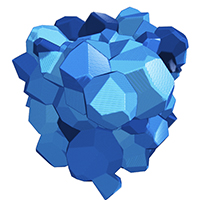

Ceramic foam

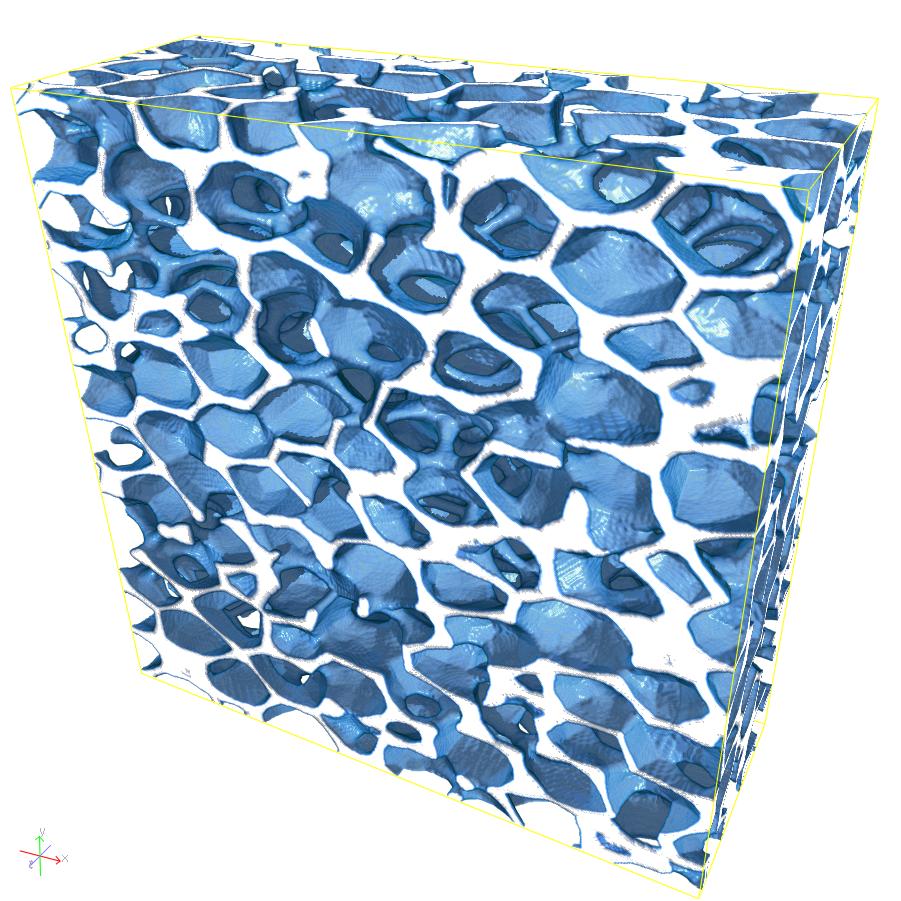

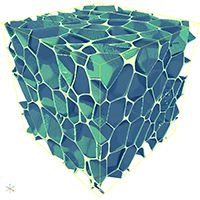

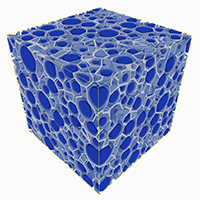

Models for cellular materials are random tessellations, that is space-filling systems of non-overlapping polytopes. A particularly versatile model are Laguerre tessellations - a generalization of the well-known Voronoi tessellation allowing to control the cell sizes much better: Each generating point is assigned a weight that can be interpreted as a sphere radius. The cell volume distribution of a Laguerre tessellation generated by a system of non-overlapping spheres is closely related to the sphere volumes.

The model is fit by minimizing a distance function between several characteristics of the model and the real microstructure where the latter are measured from 3D image data. Modelling combined with numerical simulation of materials properties enables optimization of the microstructure.

Closed cell rigid polymer foam

Publications

- Redenbach, C.; Schladitz, K.; Vecchio, I.; Wirjadi, O.:

Image Analysis for Microstructures Based on Stochastic Models.

GAMM-Mitteilungen. 37, (2), 281-305, (2014).

- Vecchio, I.; Redenbach, C.; Schladitz, K.:

Angles in Laguerre Tessellation Models for Solid Foams.

Computational Materials Science, Volume 83, Pages 171-184, ISSN 0927-0256, (15 February 2014).

Article.

- Redenbach, C.; Wirjadi, O.; Rief, S.; Wiegmann, A.:

Modelling of Ceramic Foams for Filtration Simulation.

Advanced Engineering Materials 13 (3), S. 171–177, (2011).

- Redenbach, C.:

Microstructure Models for Cellular Materials.

Computational Materials Science 44 (4), S. 1397-1407, (2009).