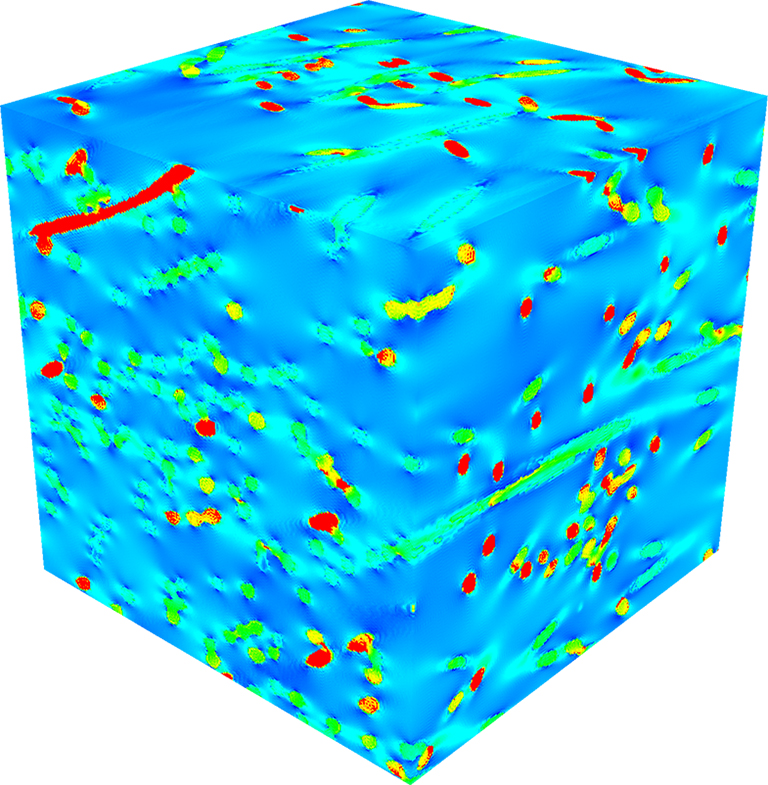

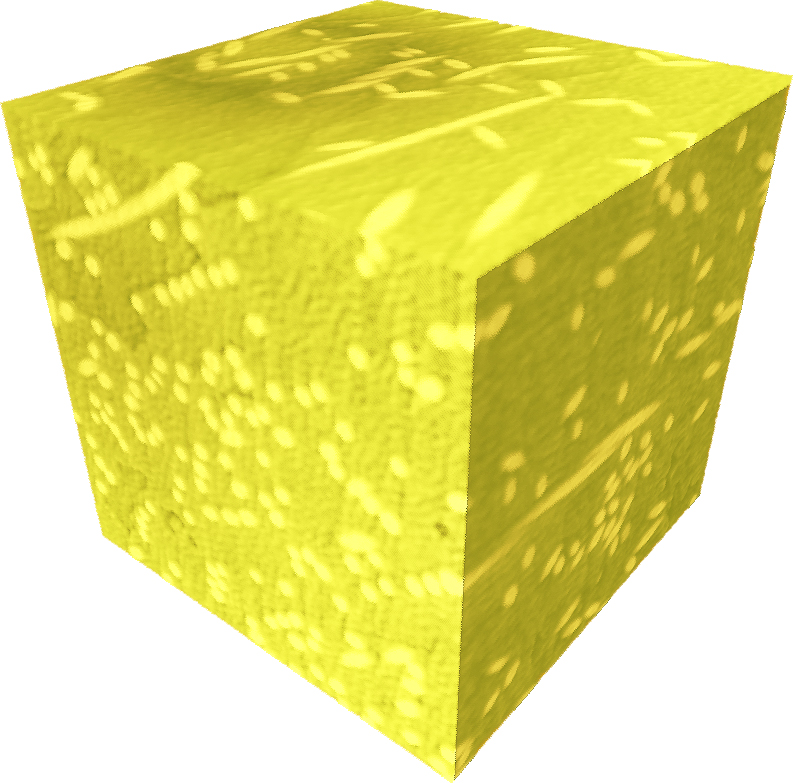

The microstructure accounts strongly for material properties like thermal conductivity, stiffness and strength, or acoustic absorption. 3D image analysis can provide geometric information to replace phenomenological constitutive laws for the macroscale by multiscale models taking into account both the constituent's bulk properties and their spatial structure. That way, the material's behaviour at the macroscopic scale can be predicted much more precisely.

For example, the mechanical stiffness of a glass fiber reinforced polymer differs strongly depending on whether it is loaded in fiber direction or perpendicular to the fibers. This anisotropic behaviour is captured by the fiber orientation tensor attainable from 3D images. Stiffness and strength computed as functions of the fiber orientation result in the full 4th order anisotropic stiffness tensor.