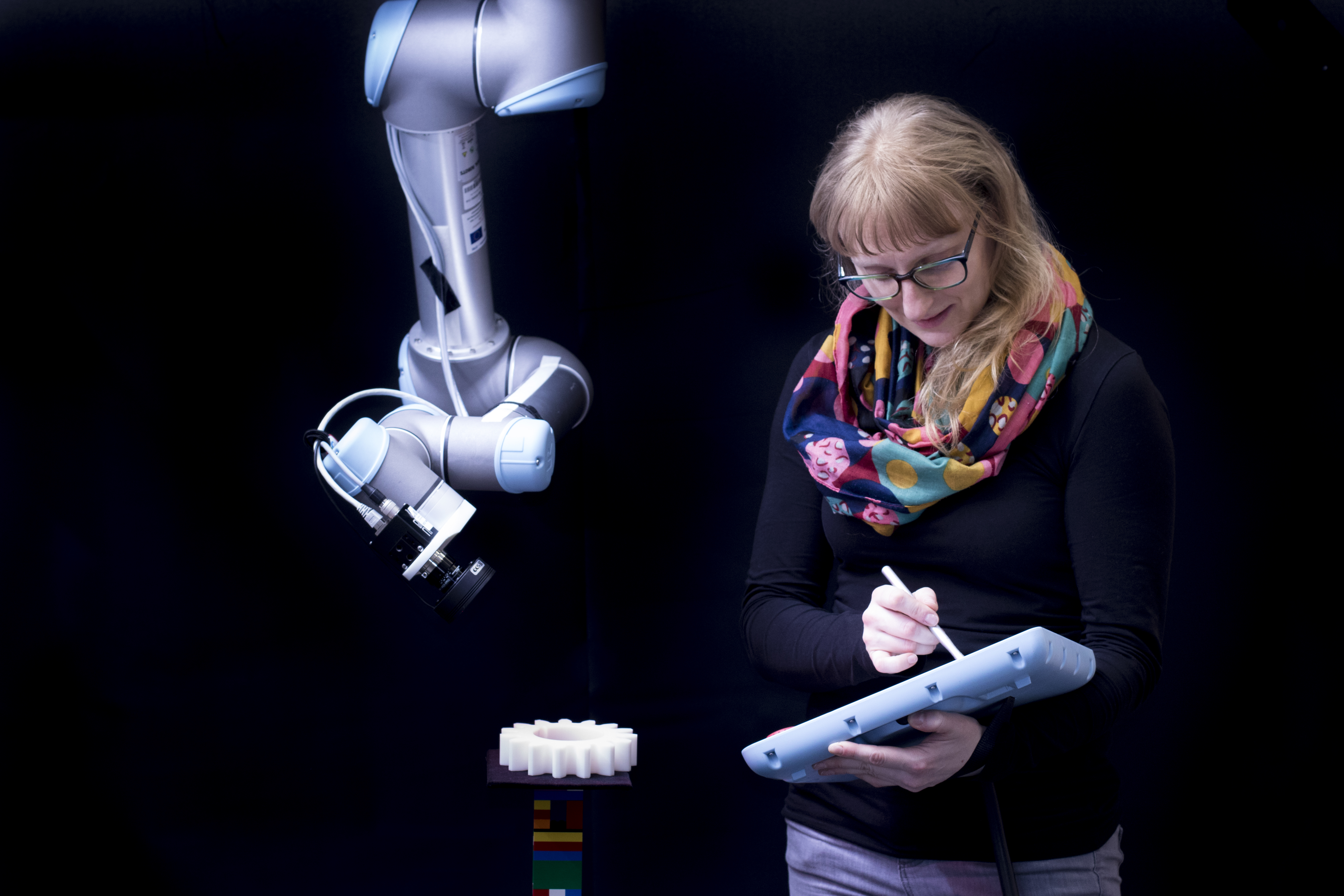

In the project, we are developing »eQuality«, a digital defect library that supports companies from the production sector in the inspection with Artificial Intelligence (AI) and in the standardized recording of defects. At the same time, it is intended to enable virtual inspection planning processes that recognize application-relevant defects and generate realistic training data sets for the AI. Borderline cases are also taken into account.

From household items to components for vehicles or in aviation through to medical technology – when manufacturing products, even the smallest defects need to be detected reliably, quickly and automatically. The manufacturing market requires flexible inspection solutions that

- can be integrated into their digital twin

- are optimized and verified through simulations

- can be used again and again

Such automated inspection systems are expensive and take a lot of time and expertise to develop. They usually cannot be used in the same way for all products and are often difficult to transfer to all processes.