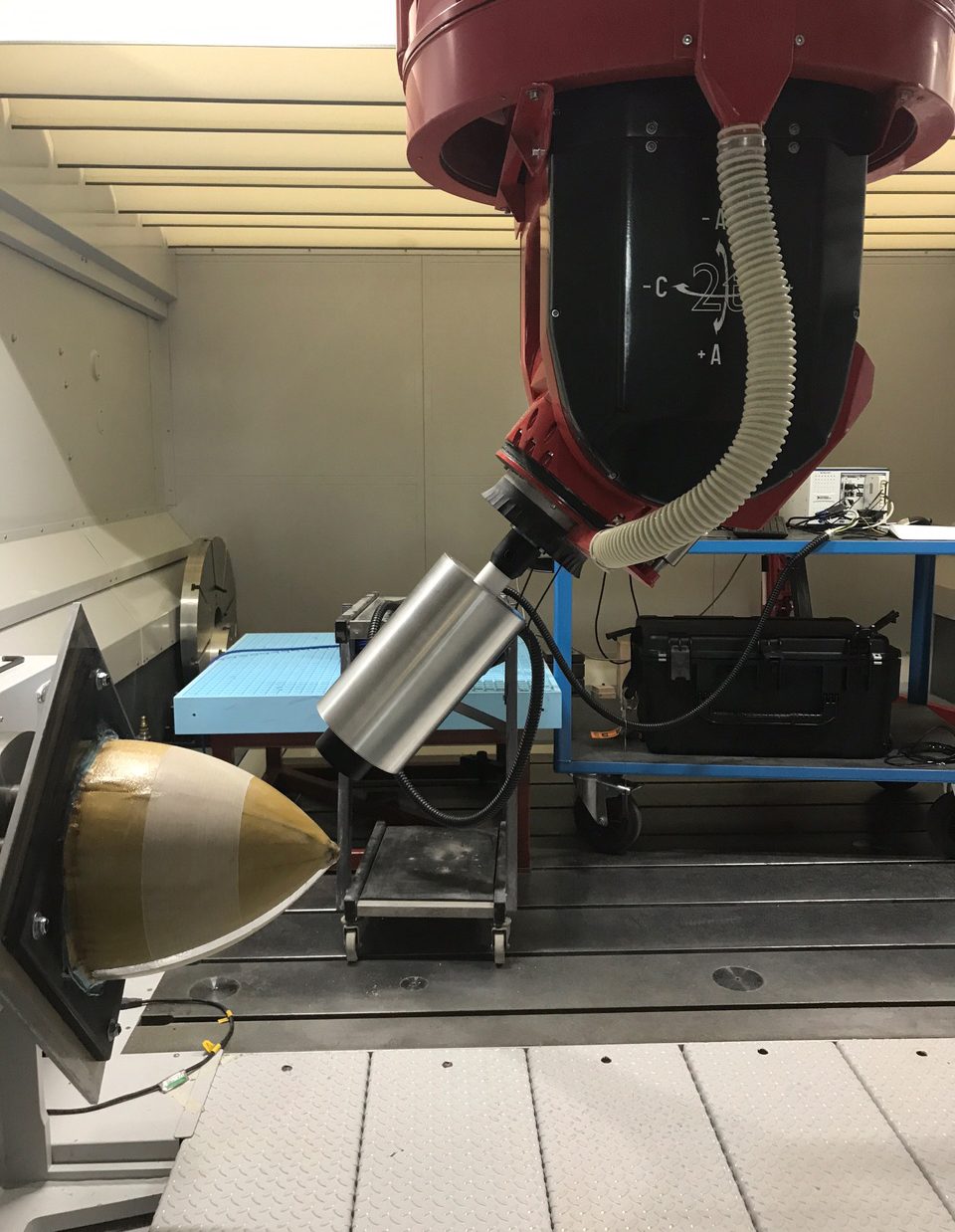

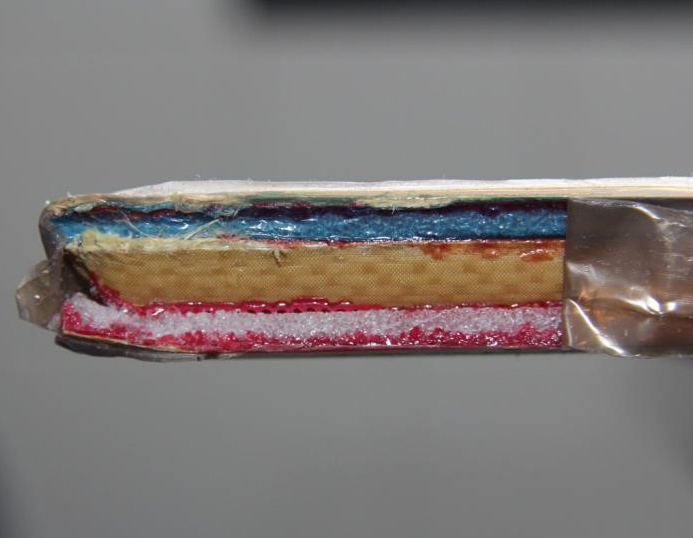

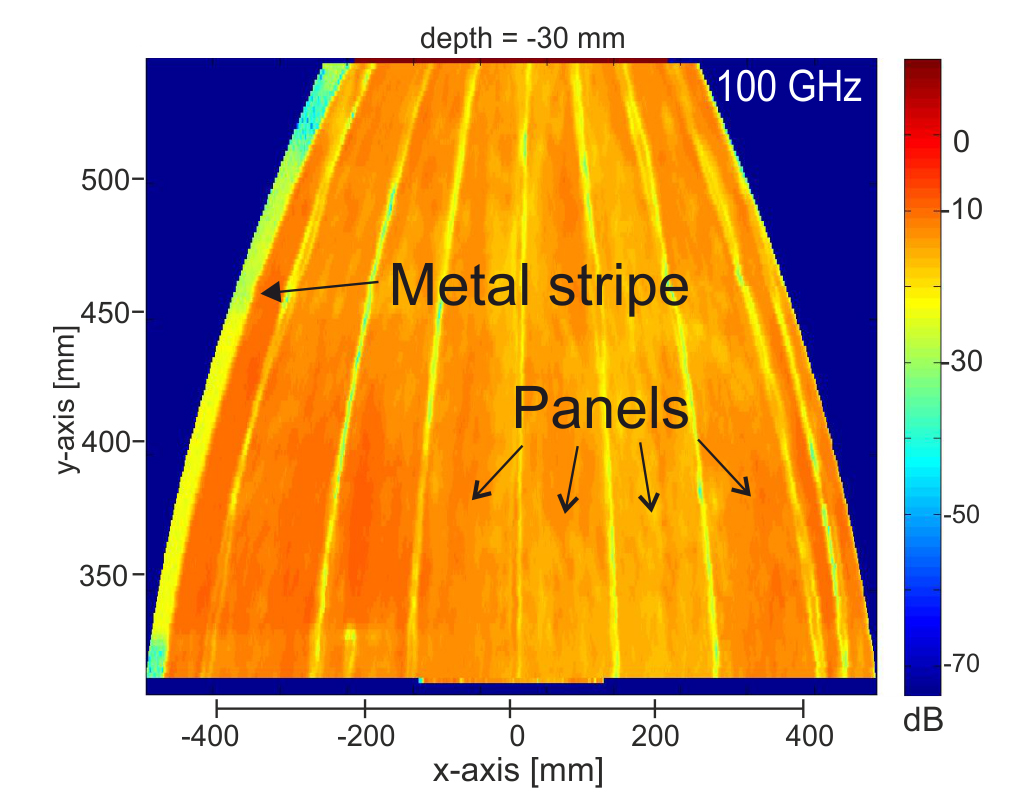

Imaging testing with terahertz waves is ideally suited for the non-destructive inspection of fiberglass-reinforced composite materials. Such structures are used, for example, for radar domes (radomes) of aircraft, among other things to protect the sensitive radar technology. Terahertz technology enables non-contact inspection of the structure's properties in the field or directly during manufacture.

Requirements for the Radome

Radar domes must withstand harsh weather conditions and impacts. They are routinely inspected in the field, but already during production their structural integrity and transmission properties for radio signals must be optimized. Previously used testing techniques such as ultrasonic methods and knock tests can only be used for this purpose to a limited extent and possibly only under special conditions.

Testing with terahertz waves allows non-contact and non-destructive examination of the external and internal structure of composite materials at each manufacturing step or even in the field. Furthermore, we use image processing methods for the automatic detection of defects or other features.