Additive manufacturing processes have become an integral part of the production of high stress components that are manufactured in small batch sizes such as blades or fuel nozzles for gas turbines. Besides aerospace, automotive manufacturing is predestined for the use of additive manufacturing methods because of the large variety of products. In the context of the BMBF-sponsored project »CustoMat 3D«, we develop methods in this area in cooperation with our partners. The project aim is to use simulation-aided development and qualification to create custom-made aluminum alloy materials for use in laser additive manufacturing for the automobile industry.

Modeling and Simulating Additive Manufacturing by Selective Laser Fusion

Project CustoMat3D

New Options and Degree of Freedom in Design

The basic principle of additive manufacturing is the layer-by-layer manufacturing process, which eliminates many design limitations due to traditional production methods, like pre-determined tool paths or draft angles. This allows to make full use of the potential of end-use specific lightweight construction as structural components need no longer be of a generic design covering all possible load cases.

Custom Aluminum Materials for the Automotive Industry

Today's aluminum alloys are generally not customized for a specific application and do not fully exploit cost and weight reduction potentials. However, the optimal simulation approach is still the subject of ongoing research.

In cooperation with MAGMA, we are developing new approaches to simulate the extremely fast phase transitions and solidification process as well as the resulting material structures. To predict deformation, we take into account all relevant length and time scales. Specifically, we include:

- The details of the powder and melt pool in the vicinity of the laser

- The effects of the punctiform influx of heat due to the laser on the residual stress and temperature distribution throughout the component

We develop a simultaneous multi-scale method that divides the work piece into a near- and a far-field, thus properly accounting for the local physical conditions, such that we can model and detail the entire work piece.

Video: Microscale Simulation of Laser Powder Bed Fusion

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyThe video shows the simulation of a laser powder bed fusion on the microscale. Seven layers are compared side by side – each with different scanning strategies, both with and without support structure. Explained in detail:

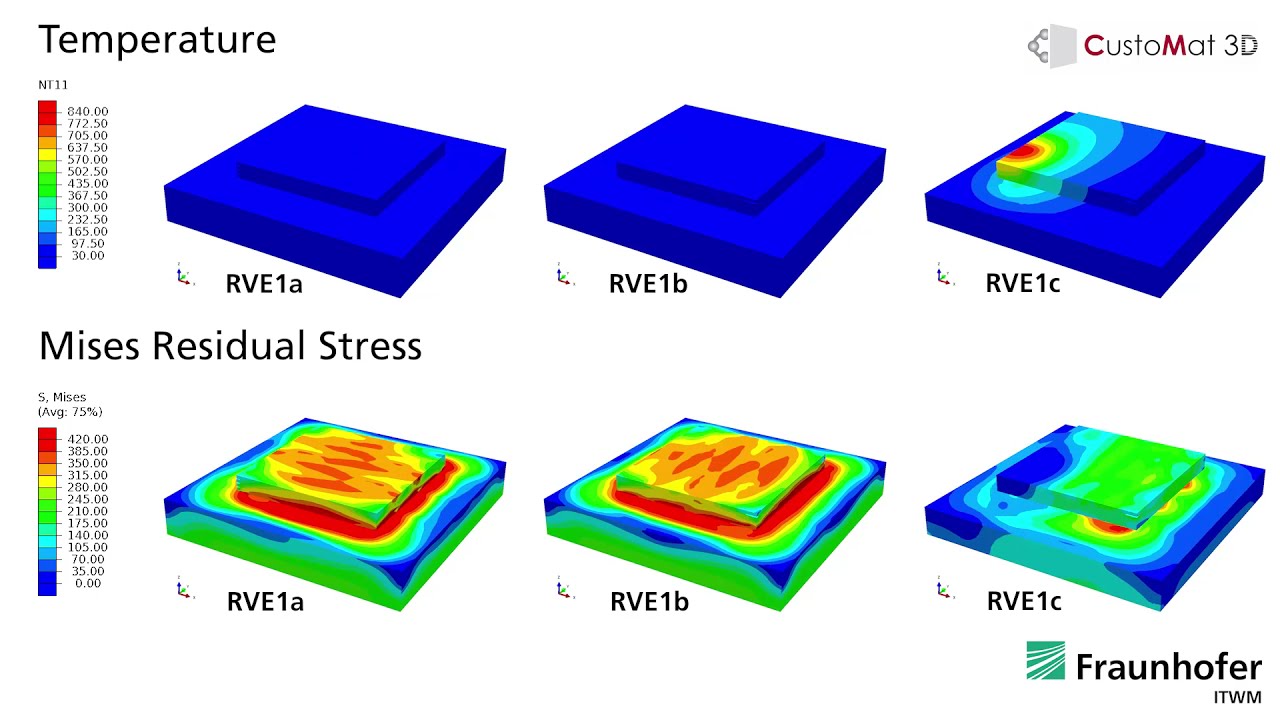

In 3D printing, high temperatures, or sharp temperature changes, cause residual stresses in the printed structures to warp the material (Technical term: warpage or warping). This can limit the functionality of the material. Particularly high and critical residual stresses often occur in the first layers printed on the base plate.

Thermomechanical simulation of the printing of multiple layers is used to optimize not only the structures themselves, but also their connection to the base plate – i.e. the support structures. In the middle column (RVE1b), compared to the left column (RVE1a), the scan direction is rotated by 90° in every second layer. In the right column (RVE1c), compared to the middle column (RVE1b), first a support structure is printed on the base plate and then the seven layers are printed on this support structure. The residual stresses are much smaller with support structure.

Partners in the Project CustoMat 3D

The project »CustoMat 3D« is funded by the Federal Ministry of Education and Research within the BMBF project and research scheme ProMat_3D. We work together with several other research institutes and our industry partners:

- Altair Engineering

- Concept Laser GmbH

- Daimler AG

- ECKA Granules Germany GmbH

- EDAG ENGINEERING GmbH

- FKM Laser Sintering

- Fraunhofer-Einrichtung für Additive Produktionstechnologien IAPT

- Leibniz-Institut für Werkstofforientierte Technologien IWT

- MAGMA Gießereitechnologie GmbH