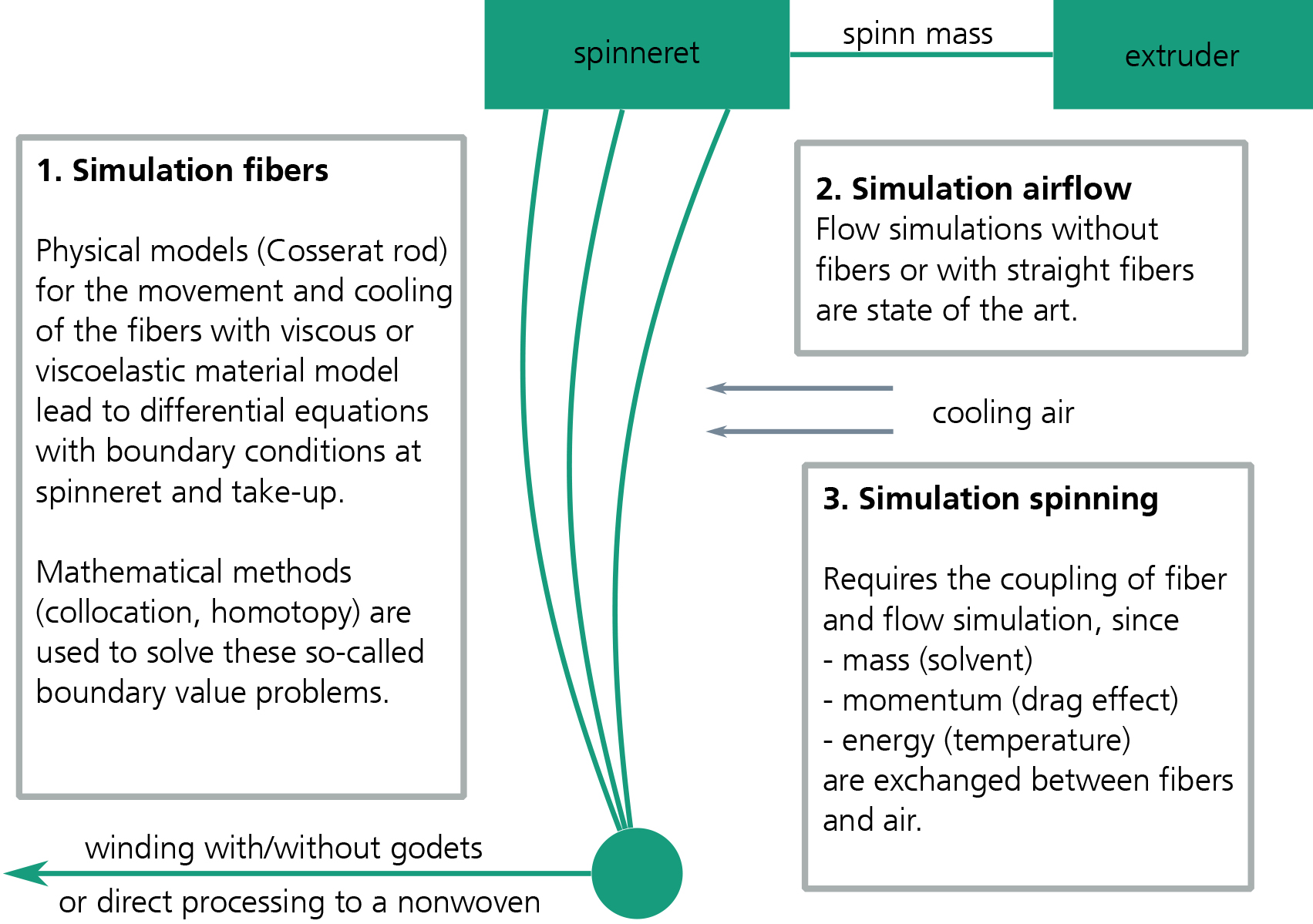

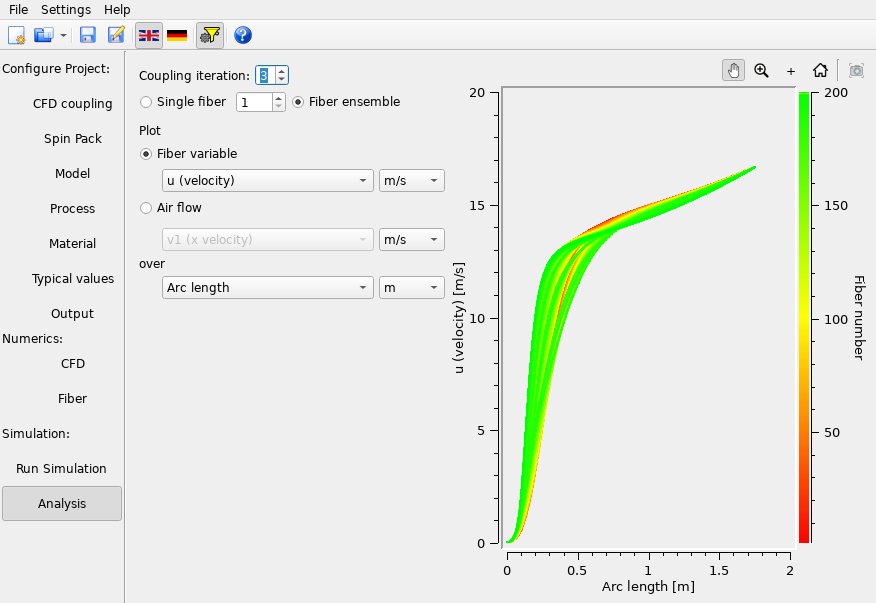

In the VISPI project, we are working together to develop simulation software that can be used to virtually map and investigate a wide range of spinning processes. The project is funded by the Federal Ministry of Education and Research (BMBF).

It is one of the oldest techniques of mankind: spinning. However, classic spinning mills that process fibers into yarn can hardly be found in Europe anymore – the majority of man-made fibers are produced in China these days. Globalization also affects the production of synthetic fibers. German fiber manufacturers are therefore focusing on »new developments with high added value«: the aim is to distinguish themselves from the mass-produced goods in Asia and still hold their own internationally. We support this vision and are developing simulation software that virtually simulates and analyses a wide range of spinning processes.

Mechanical engineering, which is part of this industry segment, is still strongly rooted in Germany. Industrial research into product and process innovation is reaching its limits on a purely experimental basis. The solution: virtual simulations.