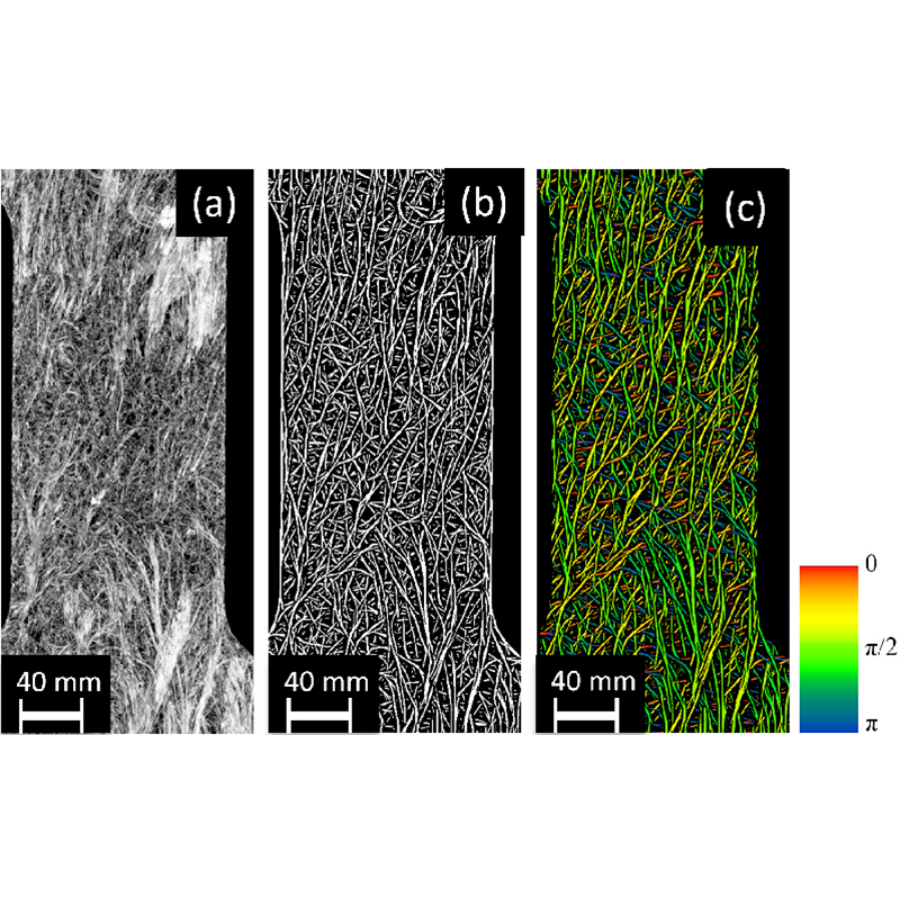

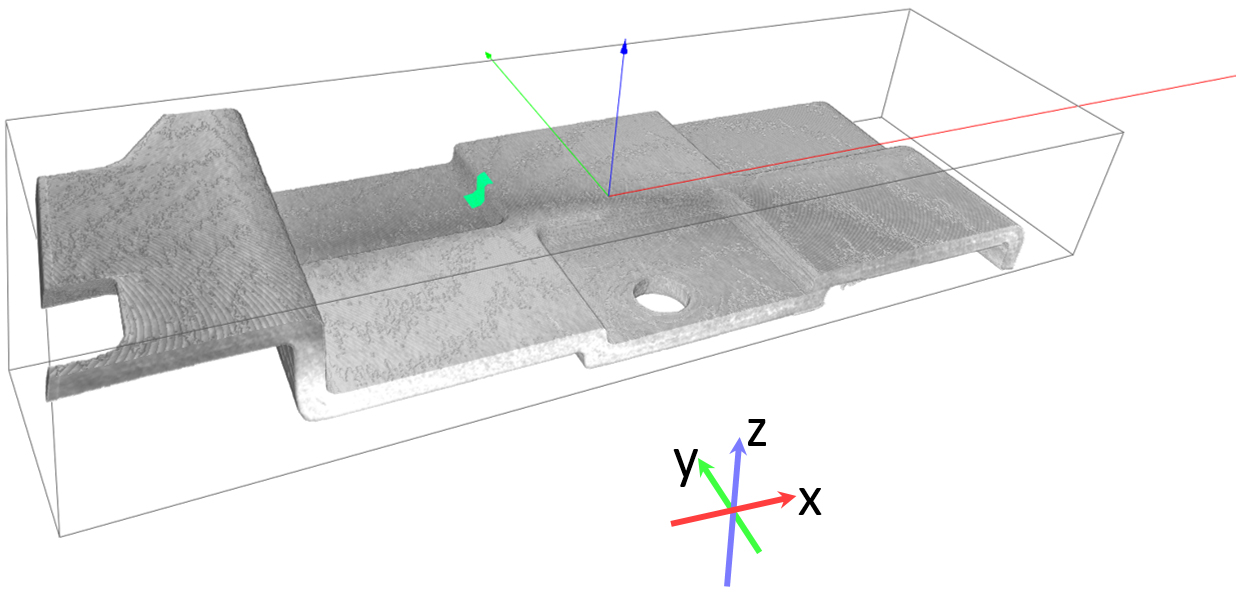

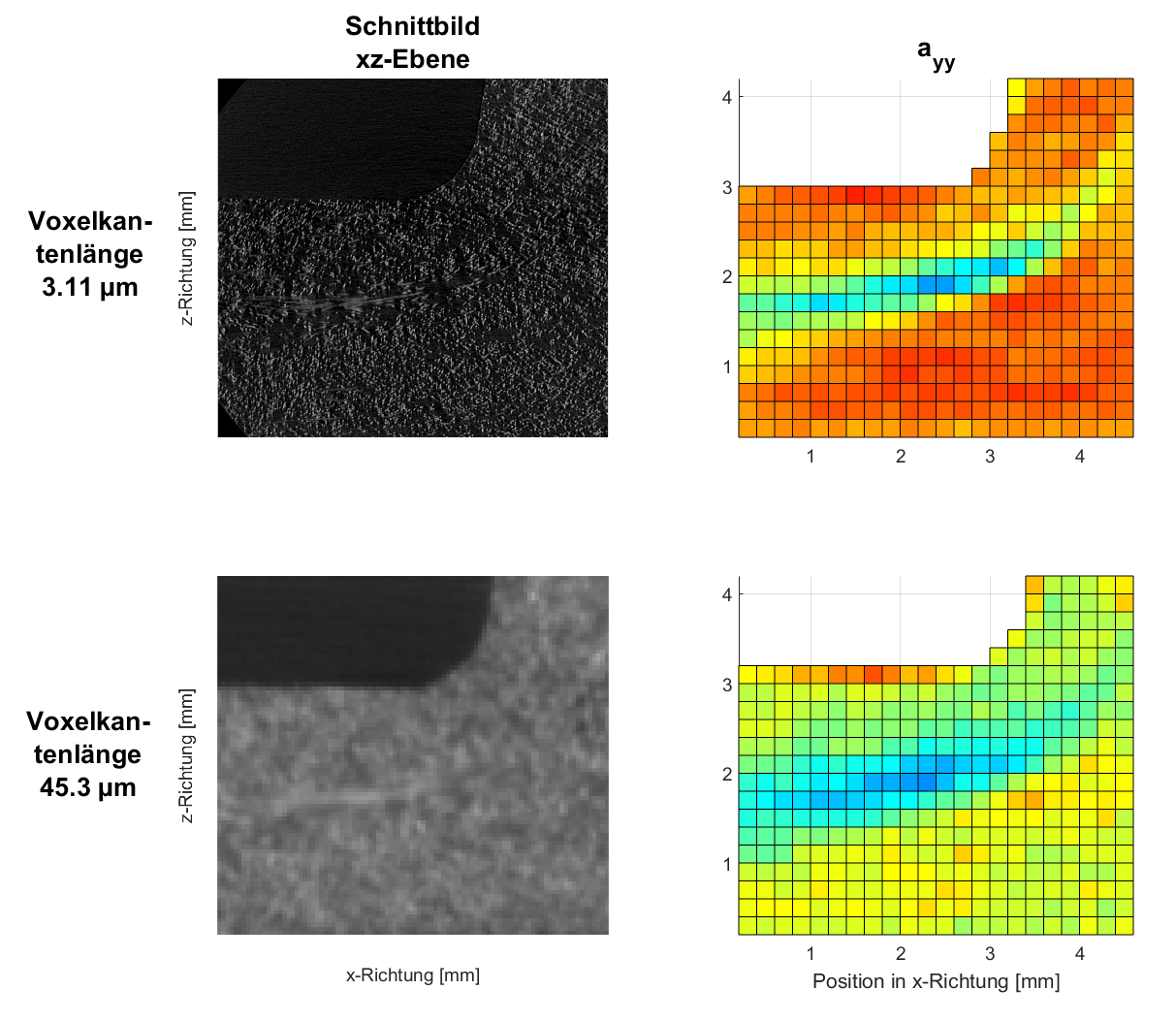

The geometry of the fiber system of fiber-reinforced polymers has a strong impact on mechanical properties of composite parts. The mechanical properties of fiber-reinforced polymers are determined by their geometry to a large extent. Examples for important parameters include the spatial fiber arrangement and the fiber direction distribution. These and other characteristics can be computed from image data using specialized image analyses algorithms. Micro-computer tomography (µCT) is well-suited for a three dimensional characterization, but two dimensional imaging methods such as scanning acoustic microscopy (SAM) can also be used.

The software package MAVI includes a number of specialized, efficient algorithms for characterizing glass (GRP) or carbon fiber-reinforced polymers (CRP):

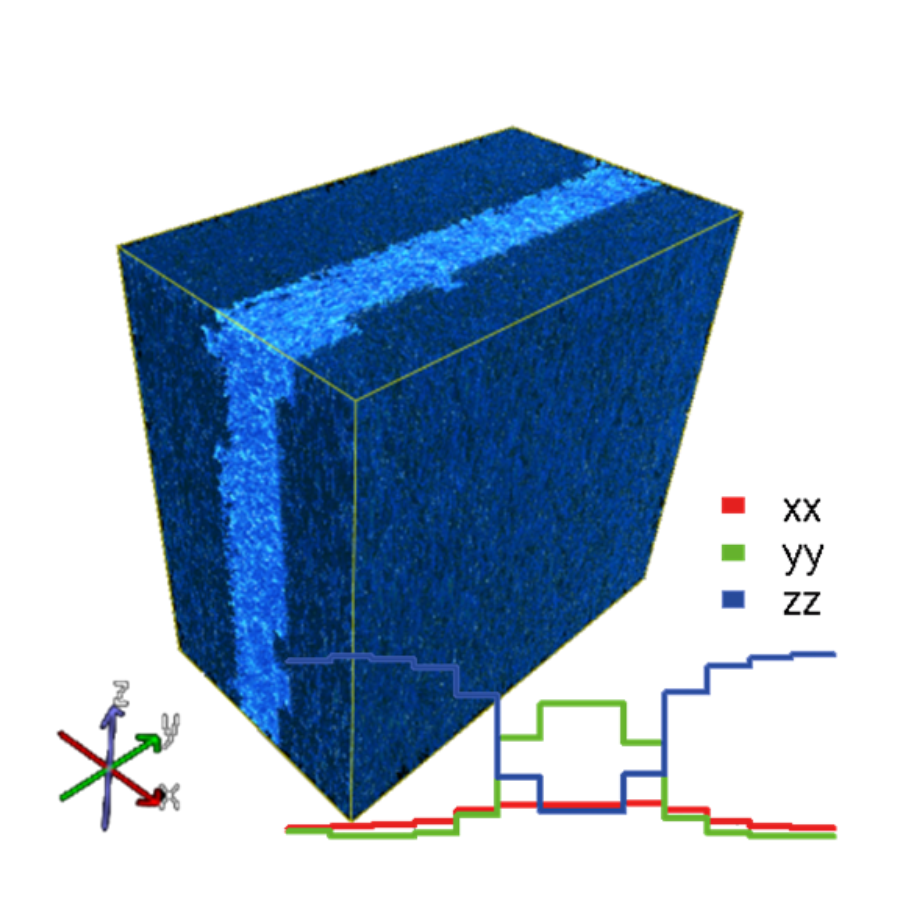

- Local fiber volume density

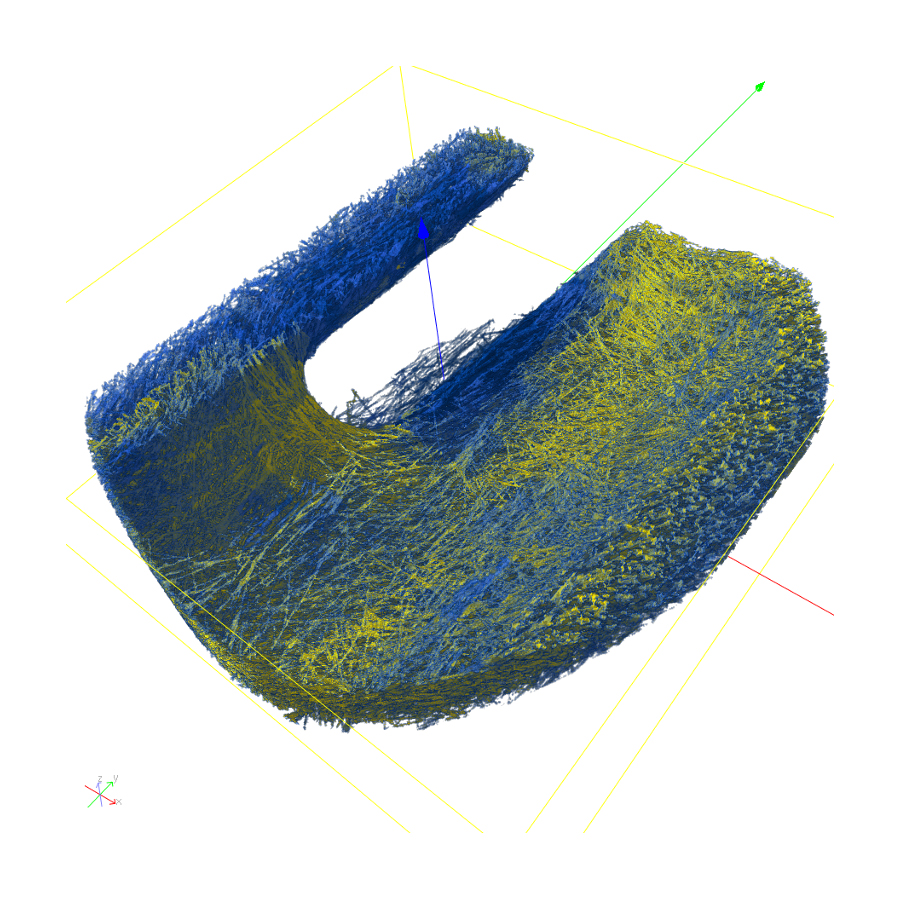

- Local and global orientation tensors

- Mean fiber direction

- Degree of anisotropy

- Specific fiber length (total fiber length per unit volume)

- Mean fiber diameter

- Visualization of local fiber densities and directions