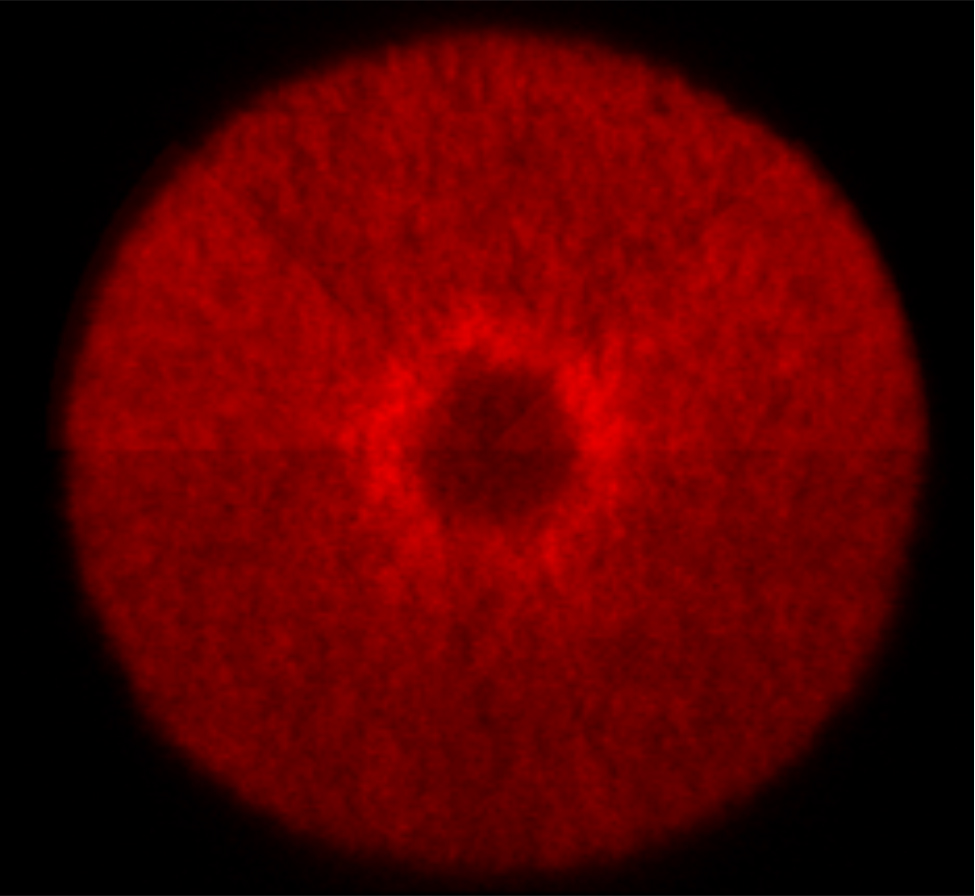

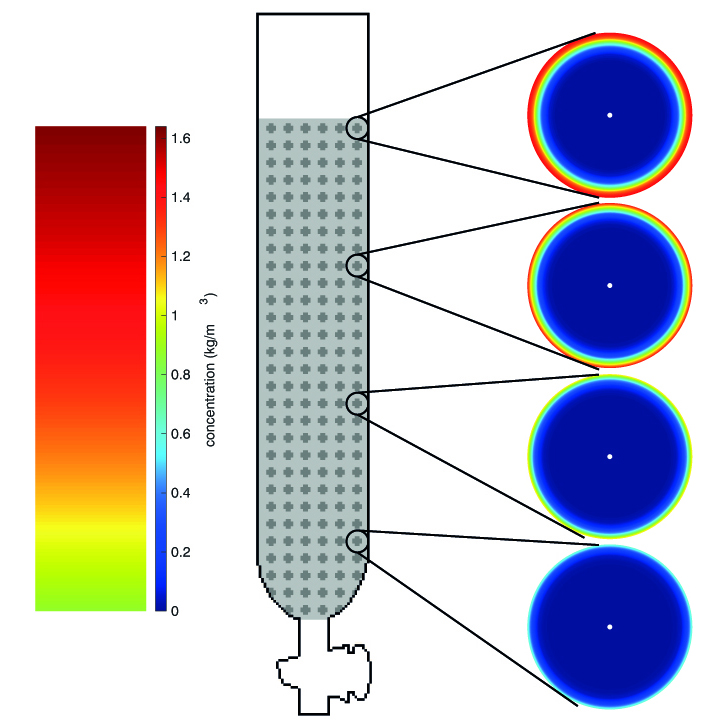

In the BMBF joint research project AMSCHA, we develop models for the simulation of separation processes of protein and cell suspensions. The abbreviation stands for »Analysis, modelling and simulation of chromatographic purification processes«. In collaboration with researchers from the Rheinland-Pfälzische Technische Universität Kaiserslautern-Landau (RPTU) and the University of Applied Sciences Darmstadt, the processes are investigated on different length scales. The chemical and pharmaceutical company Merck KGaA and the manufacturer of optical microscopes Leica Microsystems support the research project as industrial partners.

The separation of target substances from a suspension is an important and often undervalued step in the manufacturing of agents in the pharmaceutical industry, although one cannot imagine laboratory and industrial work without chromatography as a separation process. One well-established form is column chromatography. The efficiency and the throughput of these columns strongly depend on the process conditions and the used chromatographic media.