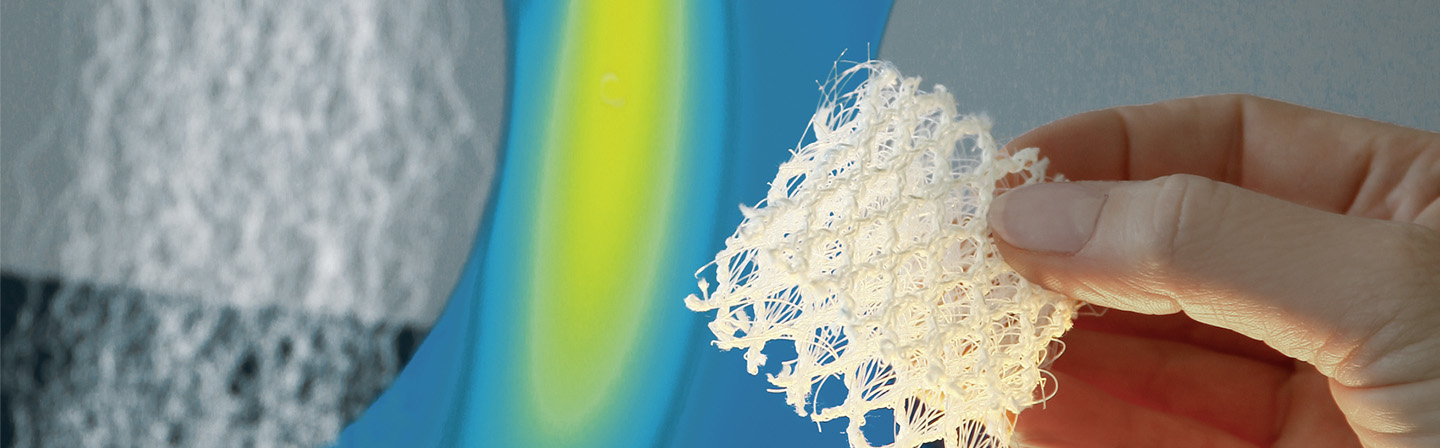

We use mathematical methods for a wide range of applications in the textile industry. From the classic material simulation of various knitted or crocheted fabrics, we also analyze and optimize spinning processes or inspect leather for faults and quality with our image processing expertise.

Click here to go to the Research Area TECHNICAL TEXTILES