In the production of nonwovens a nonwoven web is created by spinning and entangling a large number of filaments or fibers. For several years, our department has been collaborating with a broad range of industry partners to advance the virtualization of these production processes.

Due to the complexity and different physical scales involved, a multitude of mathematical challenges arise which cannot be solved with off-the-shelf simulation software. We have developed special methods and tools to support the design and control of several key aspects of nonwovens production processes with efficient simulations.

Virtual Production of Nonwovens using SURRO

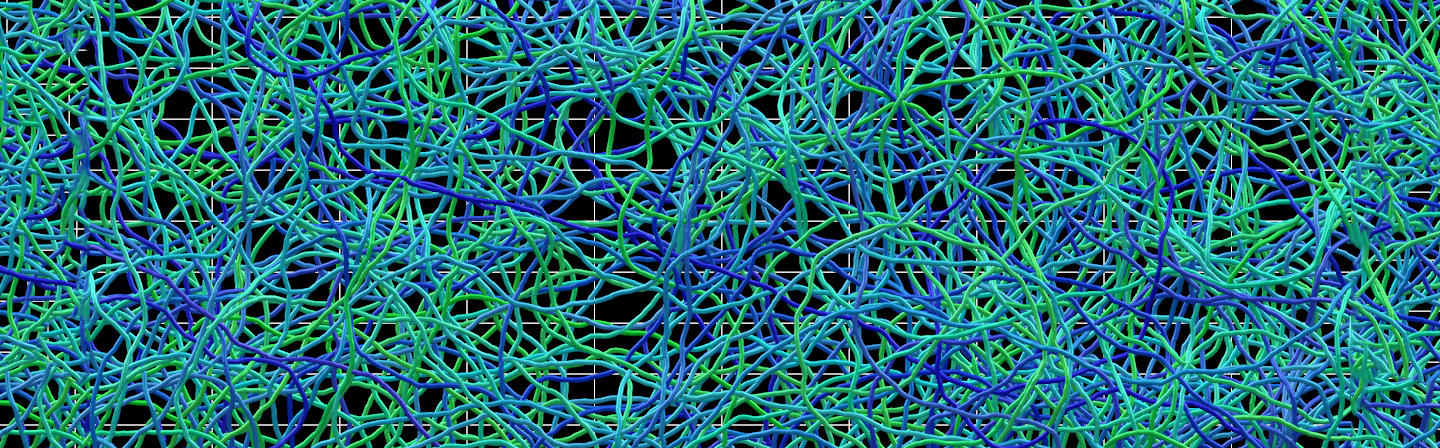

SURRO generates Virtual Nonwoven Structures

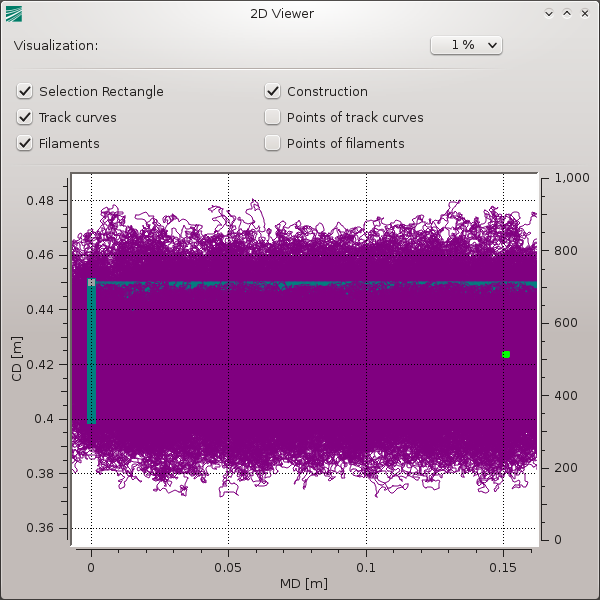

In recent years, we have developed sophisticated methods to generate large-scale virtual nonwoven structures. The resulting software SURRO (Surrogate Model) is based on a stochastic surrogate model for the simulation of filaments, which is mathematically defined by a stochastic differential equation (SDE).

The input parameters of this process are obtained by first performing physically-based simulations of a few individual filaments using FIDYST (Fiber Dynamics Simulation Tool). By means of an identification process, the complex behavior of the filaments is then reduced to a few stochastic parameters characterizing the resulting nonwoven structure.

Using SURRO and FIDYST to analyze Nonwovens Production Processes

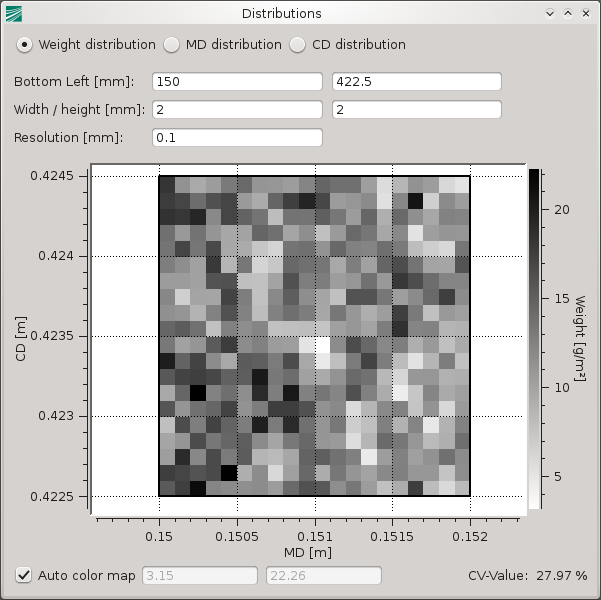

Compared to a full physical simulation, the surrogate model of SURRO provides a very efficient computation of fibers. This allows us to generate detailed microstructures of large nonwoven samples with an edge length of multiple centimeters. The generated nonwoven structure can then be analyzed with regard to weight distribution and homogeneity on different scales. The homogeneity is essential for the quality of the resulting nonwoven fabric and one of the criteria used to optimize the production process.

SURRO also contains interfaces to standard industry tools like Abaqus which can be used for additional analysis of, e.g., tensile strength. Paired with the simulation software FIDYST, we successfully use the microstructure generator SURRO to analyze and optimize the production processes for nonwoven fabrics.

3D Microstructure of an Airlay Nonwoven

The use of nonwovens is increasing continuously, especially in the automotive sector. Hence, the demand for the production equipment to manufacture aerodynamic random webs has also increased – and so, also the demand for so called Airlay units from the nonwoven fabrics producers is growing. We use our software tools to simulate airlay processes in order to optimize their design.

Further Information:

A.Klar, N.Marheineke, R.Wegener. Hierarchy of Mathematical Models for Production Processes of Technical Textiles. ZAMM, 89(12): 941-961, 2009.