Energy savings in glass manufacturing is one of the main goals of the Schott AG as it seeks the development of new concepts for the lehr and annealing furnaces. The aim is to modify the crucial subsystems of this plant such as heating and temperature tracking by implementing innovative software that promises a significant increase in profitability and energy efficiency.

In the BMWI project “Development of an energy efficient furnace concept for the thermal treatment of glass”, we are performing a contract for the Schott AG that involves model-based controls to minimize the energy input to a lehr by means of innovative actuators.

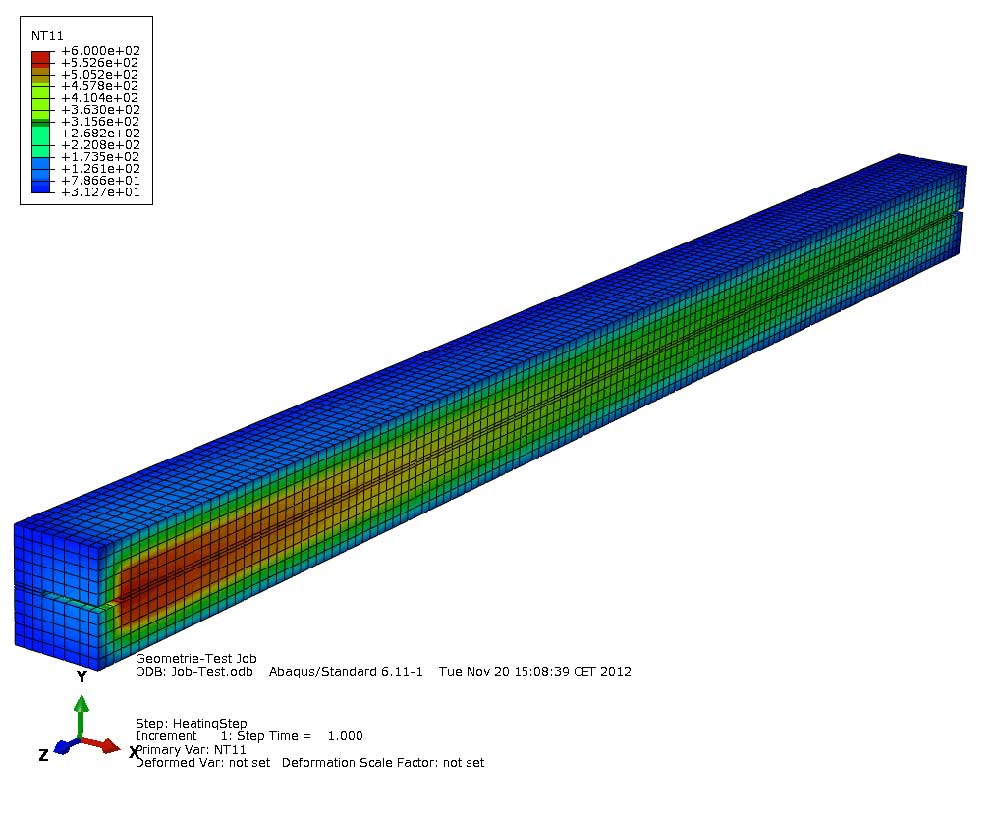

Simulation and Modeling of the Annealing Lehr

The goal of modeling is to reproduce the actual lehr dynamics as accurately as possible, including actuators and temperature sensors under dynamic conditions. By means of a simulation of this reference model, the control concept can be verified – and thus, the number of experimental test setups required is greatly reduced. Additionally, a model of lesser complexity is required as the basis for a model-based real-time capable controller.

Initially building from the reference model, we set up a simplified, linear, but nevertheless high-dimensional surrogate model which represents the lehr in its various operating points. To achieve the necessary real-time capability for the controller, the model of the lehr is decomposed into segments, a model order reduction is performed at the segment level and the reduced models are reassembled into the integrated furnace model.

This procedure yields a reduction of the model dimension by a factor of 20 with a target temperature deviation of 100 μK in the glass.