Sandwich materials are well suited for high-performance light construction applications. They are applied in aerospace, vehicle, sports equipment, and wind energy industries. Rigid polymer foams are used as core material. Reliable information on the foam structure is essential for dimensioning of sandwich light construction parts.

Analysis of Closed Foams

Analysis of micro-computed tomography image data allows to characterize the geometry of foam samples. After reconstructing the important structures, volume fraction, cell size distribution, form factors, and topological characteristics can be estimated.

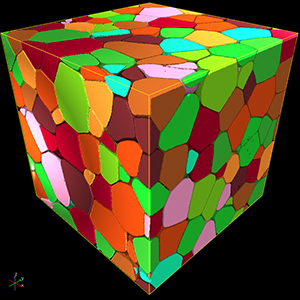

In order to study the influence of the foam meso-structure on the material properties of the foam, a stochastic geometry model will be fitted to the observed sample. Subsequently, material properties can be simulated numerically in representative volume elements.

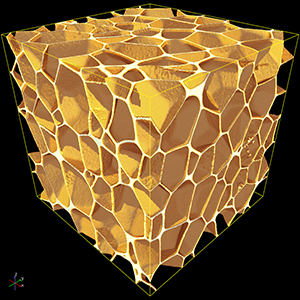

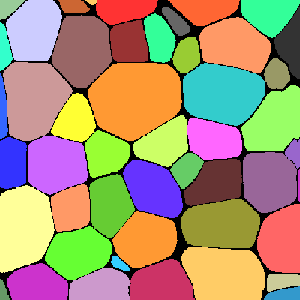

PMI rigid foam. Evonik Rohacell WIND-F RC100. Pixel edge length 2.8µm

Reconstructed Cells

2D Slice

Publications

- Vecchio, I.; Redenbach, C.; Schladitz, K.:

Angles in Laguerre Tessellation Models for Solid Foams.

Computational Materials Science, Volume 83, pp. 171-184, (2014). - Redenbach, C.; Rack, A.;Schladitz K.; Wirjadi, O.; Godehardt, M.:

Beyond Imaging: On the Quantitative Analysis of Tomographic Volume Data.

International Journal of Materials Research, 103, (2), 217-227, (2012).