The EU project »UPWARDS – Understanding of the Physics of Wind Turbine and Rotor Dynamics through an Integrated Simulation Framework« was launched in April 2018 with the aim of enabling the development of bigger and better designed wind turbines and thus increasing wind energy capacities throughout Europe and the rest of the world.

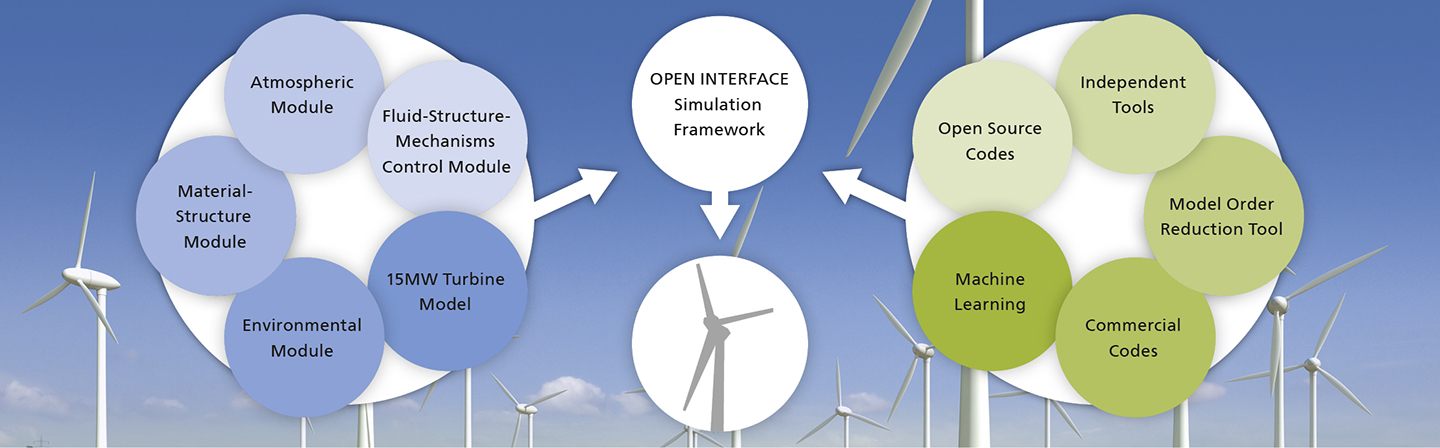

This goal will be pursued through the development of the next generation of multiphysical simulations specializing in wind flow, turbine mechanics and their interactions. These simulation tools enable a more cost-effective and faster development of prototypes for wind turbines. We are developing an integrated simulation platform as part of the project.