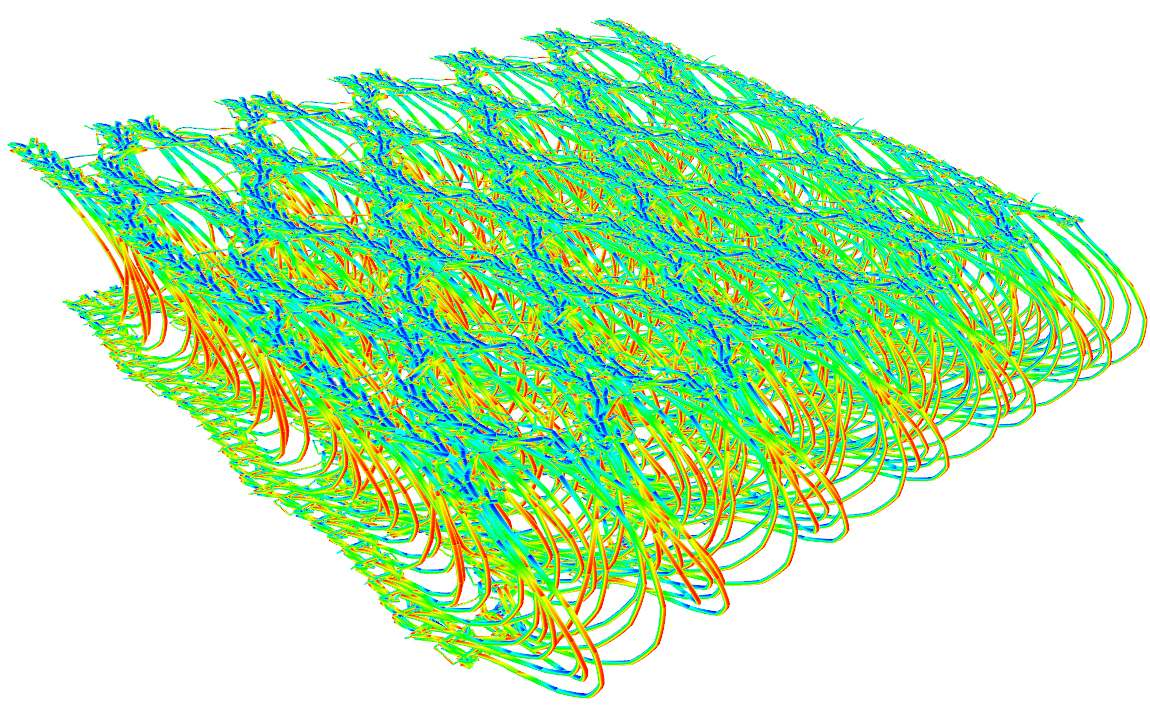

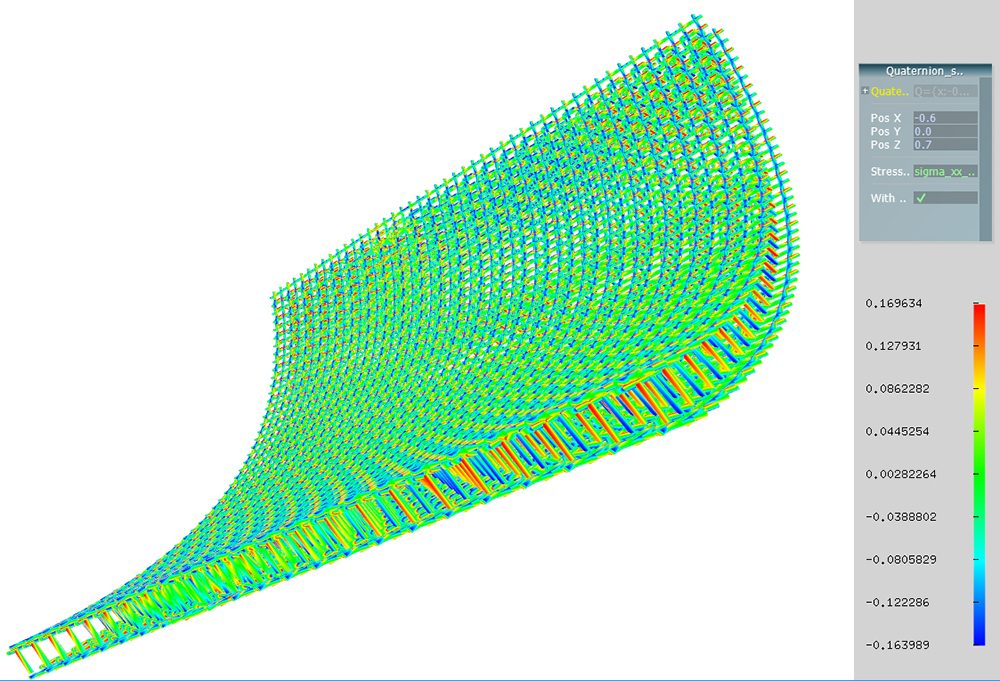

In this DFG project we analyze warp knited spacer fabrics. Warp knitted spacer fabrics are double knit textiles, in the form of plates or shells that consist of two separate layers of knit fabrics joined by vertical spacer filament yarn. They are used in various products, the areas of application include, for example, the materials used in mattresses and seats.

Through the textile production process and the selection of the thread material the properties of the warp knitted spacer fabrics are variable and adjustable. Up to now the appropriate dimensioning has been possible yet by means of an extremely time-consuming and cost-intensive experimental technique. Furthermore, deformations of the structure generated by reprocessing and using will not be considered at present. This results in problems in fitting accuracy and changed insulation and flowing behaviour of the 3D fabrics as well as the ready-madefunctional components or products.

DFG Project: Modeling the Structural Properties of 3D Warp Knitted Spacer Fabrics

In the collaborative DFG project »Modelling of the Structure and the Properties of 3D Warp Knitted Spacer Fabrics and Experimental Evaluation« with the Technical University of Dresden, which is funded by the German Research Foundation (DFG), we work on these explicit problems:

- Correct design and simulation of spacing knits using mathematical models and algorithms

- Mechanical and mathematical multiscale modeling, simulation and structural optimization considering the contact of individual fibers

- Testing methods and arrangements for 3D warp knitted spacer fabrics for charasteric values of space and location