Mathematical Models and Image Analysis Algorithms for Industry

Our department »Image Processing« develops mathematical models and image analysis algorithms and implements them in industry-standard software, primarily for production. The areas of application include, in particular, sophisticated surface inspections and the analysis of microstructures. Our products are used to gain a deeper understanding of complex geometry and structure-property relationships in materials, thus opening up new possibilities such as the optimization of material properties through virtual material design. To this end, we develop new methods and domain-specific machine learning algorithms for 2D and 3D image analysis.

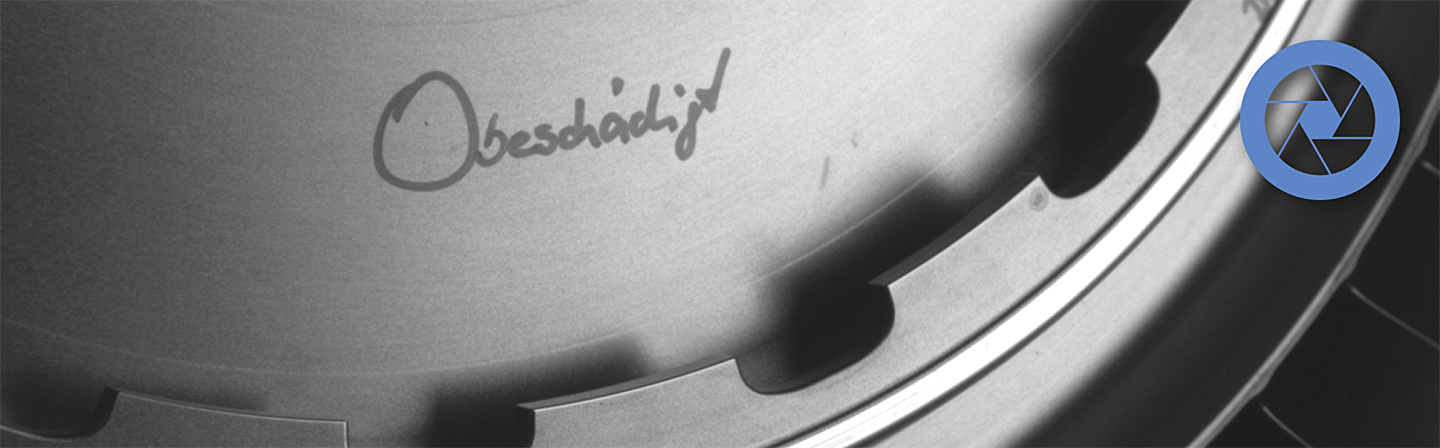

Methods such as »Deep Learning« require a large amount of annotated data, for example of defects to be found in a production plant. However, in a well-functioning production process, there are many images of defect-free products, but only a few of products with defects. We therefore often use hybrid approaches from the »classical« parameterizable methods (filters, morphology, edge detectors) and machine learning, as well as anomaly detection and data simulation.

Another field of activity is the »Microstructure Analysis«. The microstructure significantly determines macroscopic material properties. We develop algorithms for characterizing and stochastically modeling such microstructures using image data, e.g., from CT, FIB-SEM, and SEM. The latest field of activity in image processing is »Virtual Inspection Planning« where we develop complete, physically correct simulation of inspection systems. In addition to the properties of the test piece, this also includes the properties of all hardware components (illumination, camera, optics, etc.).