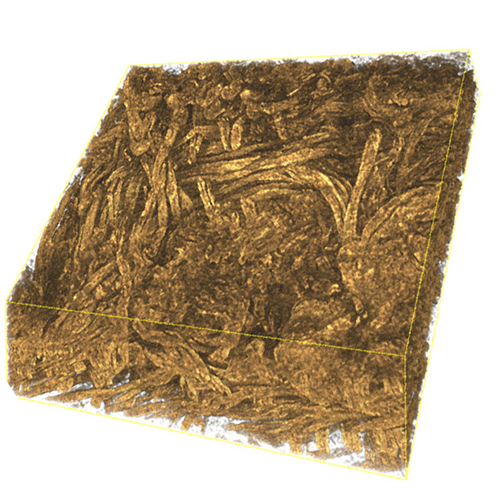

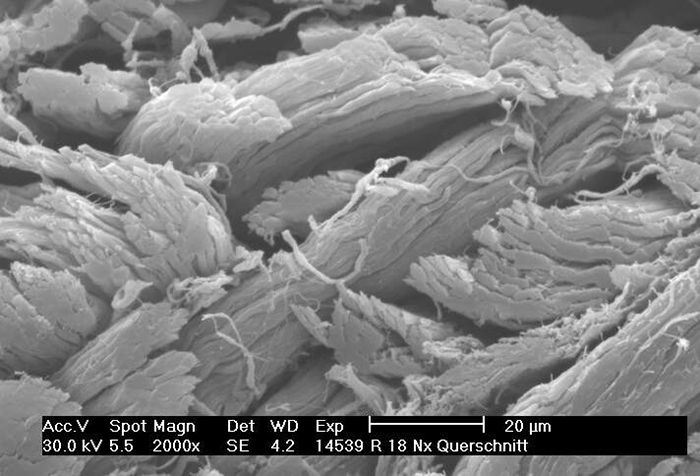

The microstructure of leather looks like long fiber bundles that are branching out into thinner networks and are interwoven in many places. Macroscopically viewed, leather is a highly anisotropic material. Leather is typically processed in car seats, furniture, clothing and shoes. The project presented here - funded by the German Federation of Industrial Research Associations (AiF) – deals with the prediction of leather properties.

The properties of leather depend on the structural arrangement of the fiber bundles, their thickness, length and viscoelastic properties. Since leather is a natural product, it shows much more non-uniform material properties than plastics and textiles. In view of the industrial mass production, there exists an increasing need to design leather-covered car and furniture seats and to evaluate the corresponding mechanical behavior in advance. In cooperation with our department »Image Processing« and the Research Institute for Leather and Plastic Sheeting (Forschungsinstitut für Leder und Kunststoffbahnen FILK), we simulate the mechanical behavior of leather by means of mathematical modelling and homogenization methods based on micro-CT images of the leather structure and the measured visco-elastic properties of the fibre bundles.

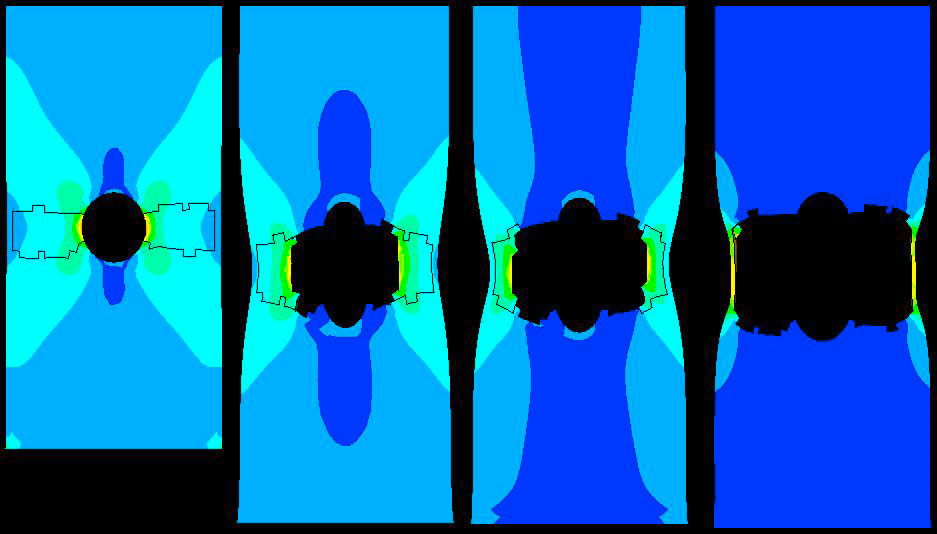

Microscopical Simulations Using the Software TexMath

The CT images taken so far show that the leather material consists of many fiber bundles whose orientation along the thickness of the layer varies considerably; the long, curved cylinders are branched, interwoven and crossed at many points. Using the measured properties of the fiber bundles, we simulate the behavior of the structure using our TexMath software. This software allows the efficient calculation of large fiber systems for large deformations with simultaneous contact sliding at millions of nodes. In this case, TexMath correctly considers the influence of frictional sliding in local fiber bundle nodes on the macroscopic leather behavior.