The universal building material concrete is strong and resistant, but brittle. Thin cracks in concrete are almost unavoidable, but usually not harmful either. For the inspection, diagnosis and maintenance of concrete surfaces, cracks must nevertheless be reliably found and evaluated. Experts often assess crack patterns purely visually.

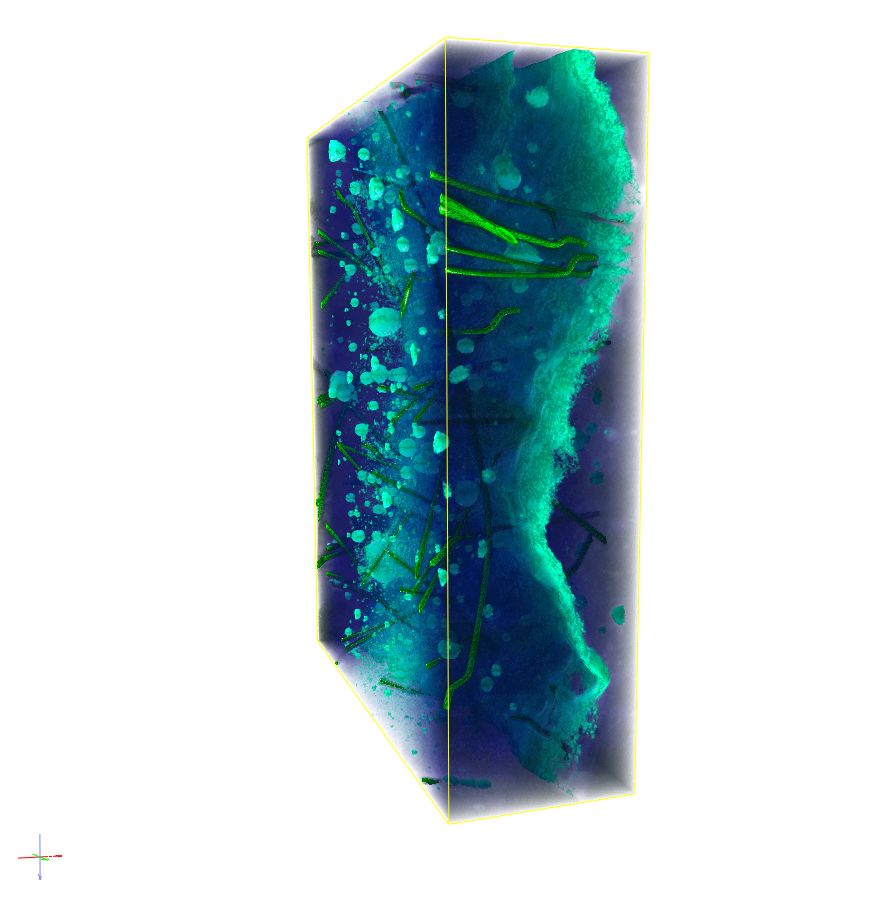

Concrete and crack structures vary greatly depending on the field of application. Concrete surfaces can be very irregular. It is therefore difficult to reliably segment thin crack structures automatically.

We have developed two very flexible and robust solutions for this task – one using classical image processing and one using Machine Learning (ML). They find hairline cracks that are only one pixel thick even on heterogeneous backgrounds.