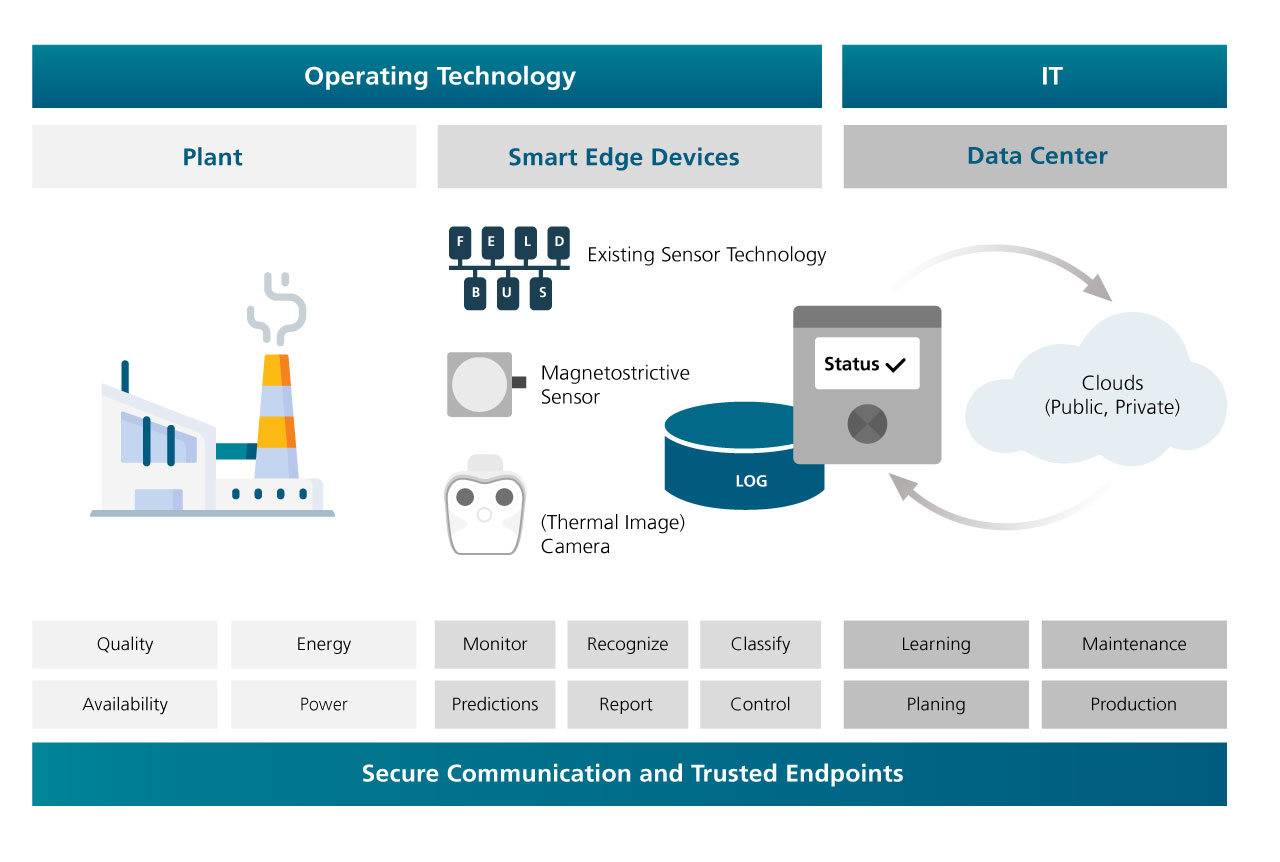

Many industrial plants have sophisticated sensor technology to control and monitor processes, the data from which is stored in their own cloud systems. In the age of the Internet of Things and 5G, however, edge computing is becoming increasingly important. Here, data is processed decentrally, i.e. »at the edge of the network«, directly locally instead of in remote data centers. In the project EMILIE, we are working with our partners to improve the electronics used for this and the edge gateways. These are designed to securely and robustly capture information, process it based on Artificial Intelligence (AI), and optimally control and monitor production processes.

BMBF Project: Smart Monitoring and Control of Processes Using Edge Computing

Project EMILIE: Embedding Machine Intelligence Logic and IT Security into Edge Devices

Optimize Processes: Linking Measurement and Sensor Data With the Digital Twin

Edge gateways are the devices within the edge infrastructure. In the EMILIE project, these include magnetostrictive sensors, high-resolution cameras and IOT gateways. Cement mills of the Gebrüder Pfeiffer SE serve as a use case in real production operations. Based on the technical measures to be implemented within the complex processes of the industrial plant, we measure concrete improvements – be it in throughput, energy efficiency or operational wear – in order to then optimize.

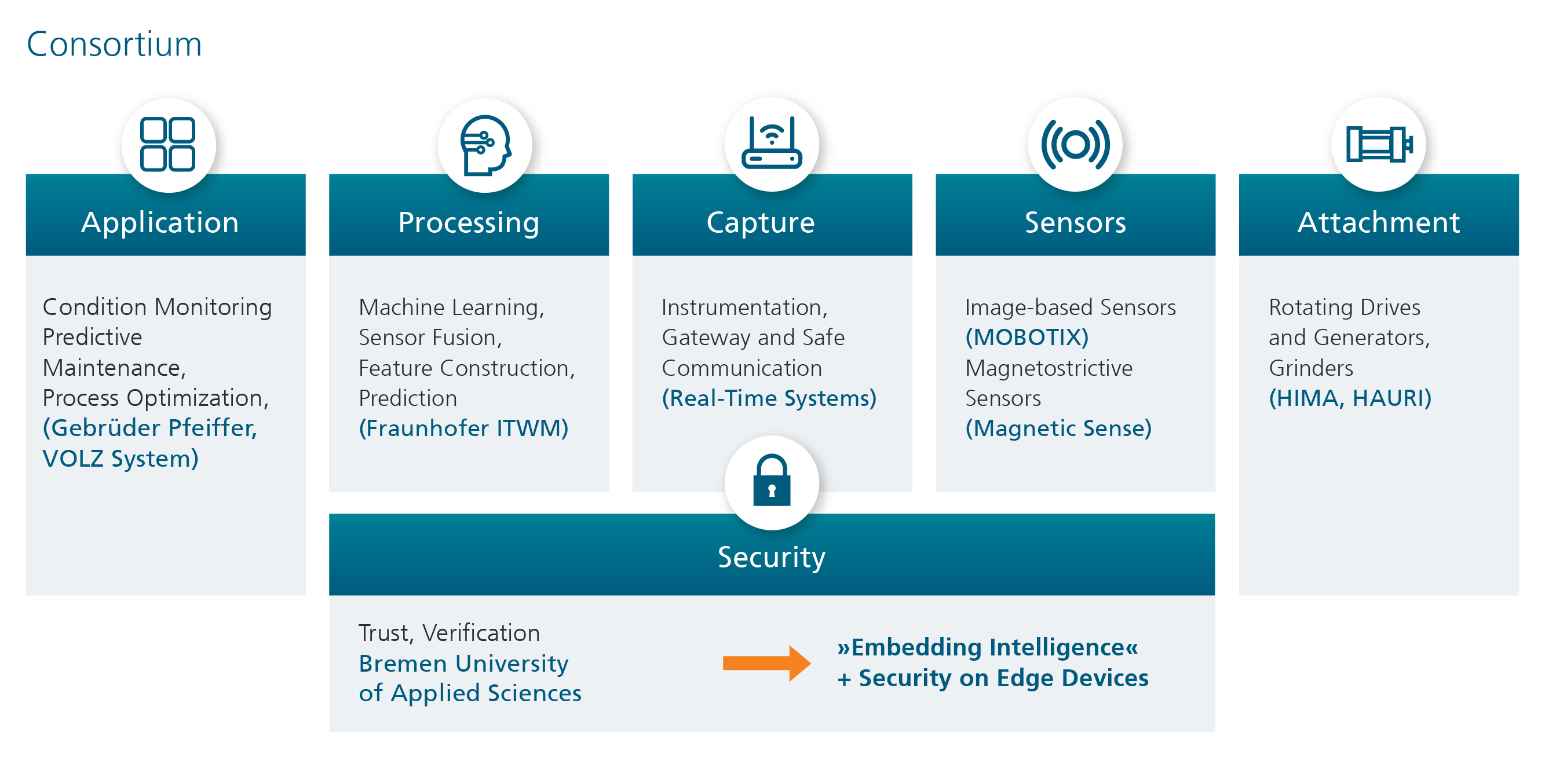

The Partners and Their Competencies Are Divided as Follows:

- Real-Time Systems GmbH, part of the congatec group, coordinates the project, contributes with cyber-secure edge gateway ARENDAR from congatec’s solution portfolio and is responsible for the prototypical development of a co-processor card to strengthen edge computing capability.

- The Gebrüder Pfeiffer SE provides the use case in the form of mills in the company's own technical center. The company's extensive mechanical and process engineering expertise provides the basis for developing the condition monitoring and process optimization applications.

- The Computer Networks and Information Security Research Group (FRI) at Bremen University of Applied Sciences is contributing IT security expertise to the project.

- The Magnetic Sense GmbH provides the torque sensors as well as the shaft design know-how.

- The Mobotix GmbH contributes the industrial camera systems with decentralized image processing and data storage.

AI and Machine Learning From Fraunhofer ITWM

Our interdepartmental team stands for the mathematical competences and develops the appropriate AI methods. This means that we implement the Machine Learning (ML) methods that are used in signal and image data processing and are executed by the edge devices.

Within EMILIE, our work forms the interface between the application and the microelectronics to be developed. We extend the application of the devices by intelligent algorithms.

In close cooperation with the partners, we integrate the extensions of the hardware components into two concrete applications (grinding plant and gas turbine) in order to make the plant operation more energy efficient and to minimize wear and tear.

At the end of the project, there should be an implemented reference system that enables the following:

- Condition monitoring – locally distributed across the plants, near real-time and traceable.

- Predictive maintenance of the plant

- Control through AI-based edge computing

An Overview of Our Project Partners

- Real-Time Systems GmbH (project coordination)

- Gebr. Pfeiffer SE (GPSE)

- Magnetic Sense GmbH (MS)

- Mobotix AG Camera Manufacturer

- Bremen University of Applied Sciences, Computer Networks and Information Security Research Group (HSB)

For the effective implementation of a complete system including evaluation by plant operators, the EMILIE network thus covers the entire value chain. The developed system software including implemented AI procedures for data processing are also made available as a software library in addition to scientific articles.

Project Duration and Funding

The project is scheduled to run for three years from 01.08.2022 to 30.06.2025. EMILIE is funded by the German Federal Ministry of Research, Technology and Space (BMFRT).