Our software tool TexMath is a modular program for simulating mechanical material properties and optimizing textile products as well as multi-scale problems for textile applications.

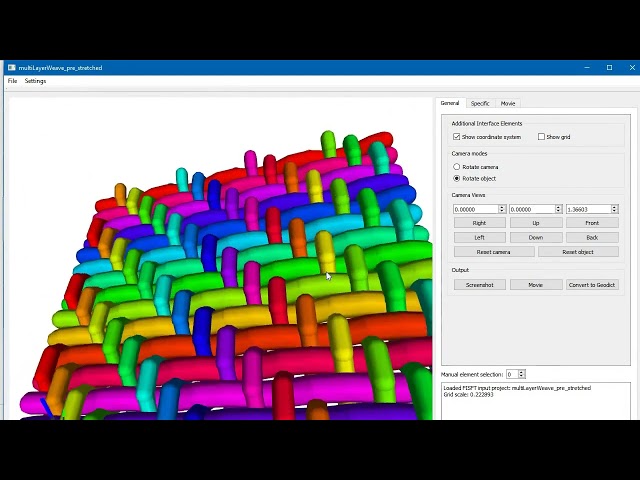

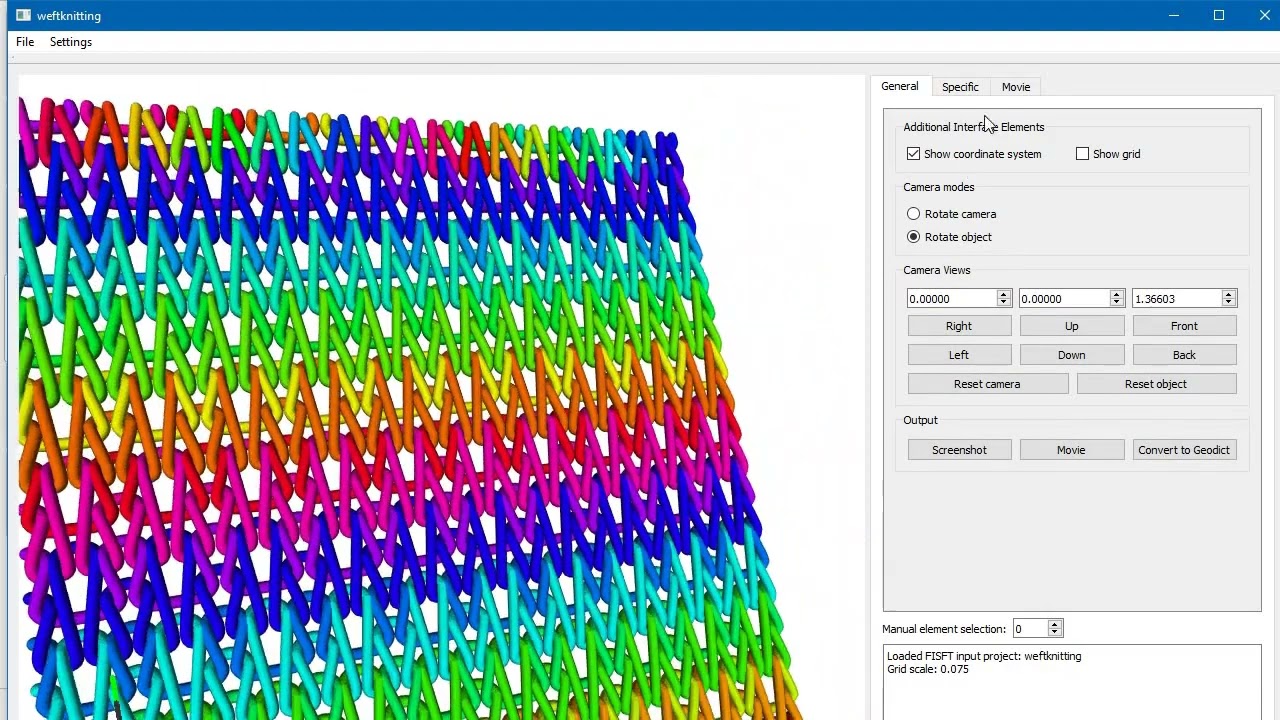

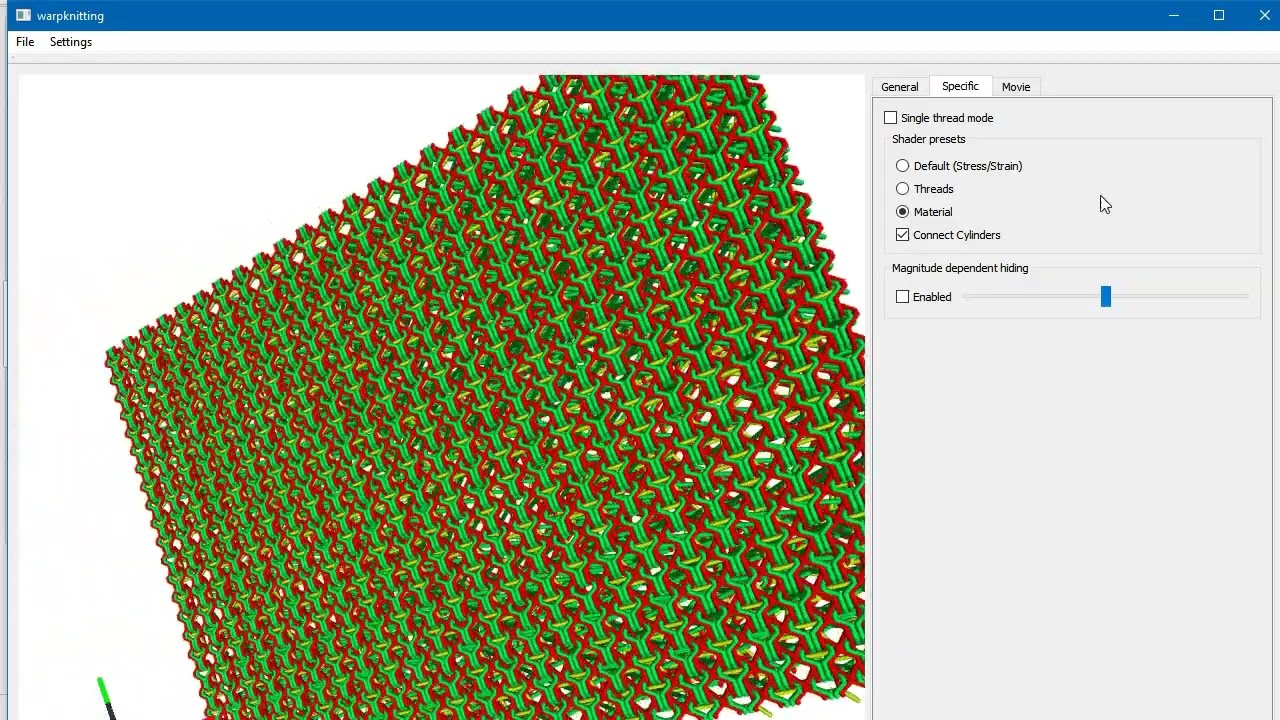

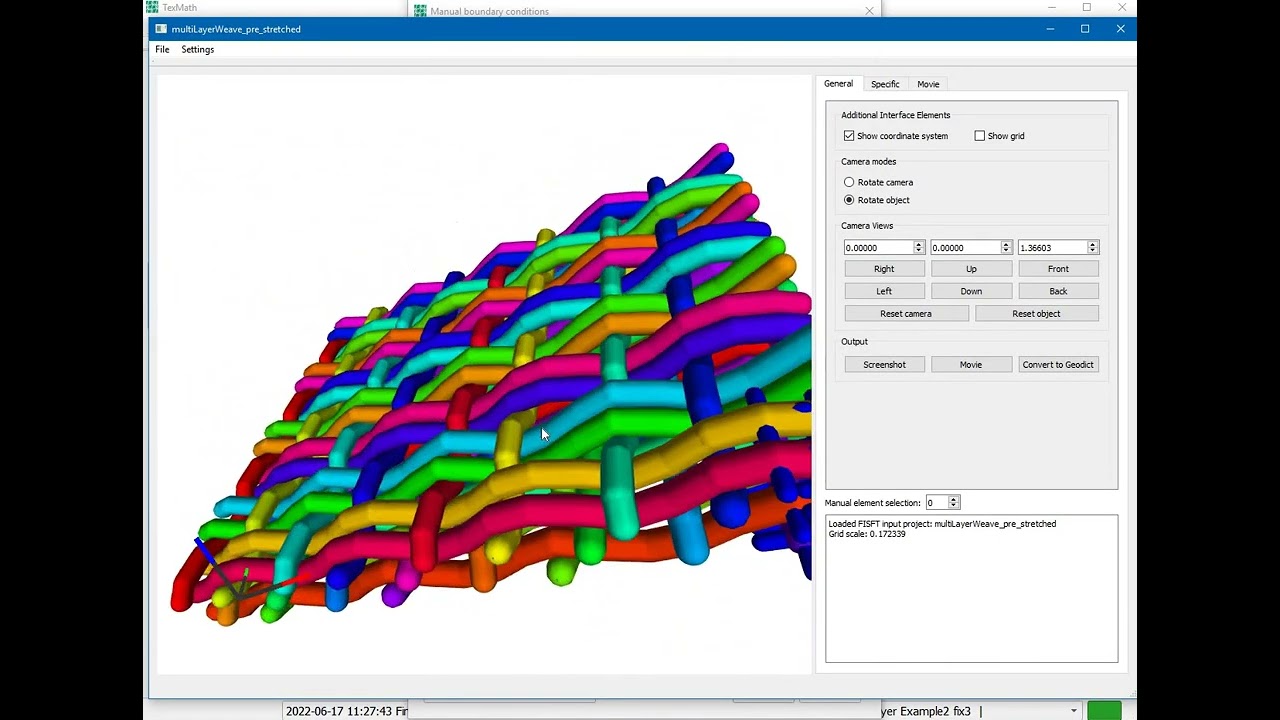

- MeshUp creates periodic textile structures of all kinds (woven fabrics, knitted warp and weft fabrics, spacer textiles) according to the respective machine control with complex weaves/knitting looping diagrams.

- FiberFEM calculates effective mechanical properties (bending, tension, shear, compression) for the textile structures created with MeshUp.

- FISFT simulates complex load scenarios on textiles (e.g. stretching, draping) or even the textile production process such as knitting.

All tools have interfaces to each other and also to GeoDict (optionally to Ansys/Abaqus as IGES-formats) in order to perform further fluid mechanical simulations on the textiles, e.g. to determine their permeability in any elongation state. An interface with FeelMath allows further detailed three-dimensional mechanical simulations at specific yarn or contact points, so that strength and durability can also be investigated.