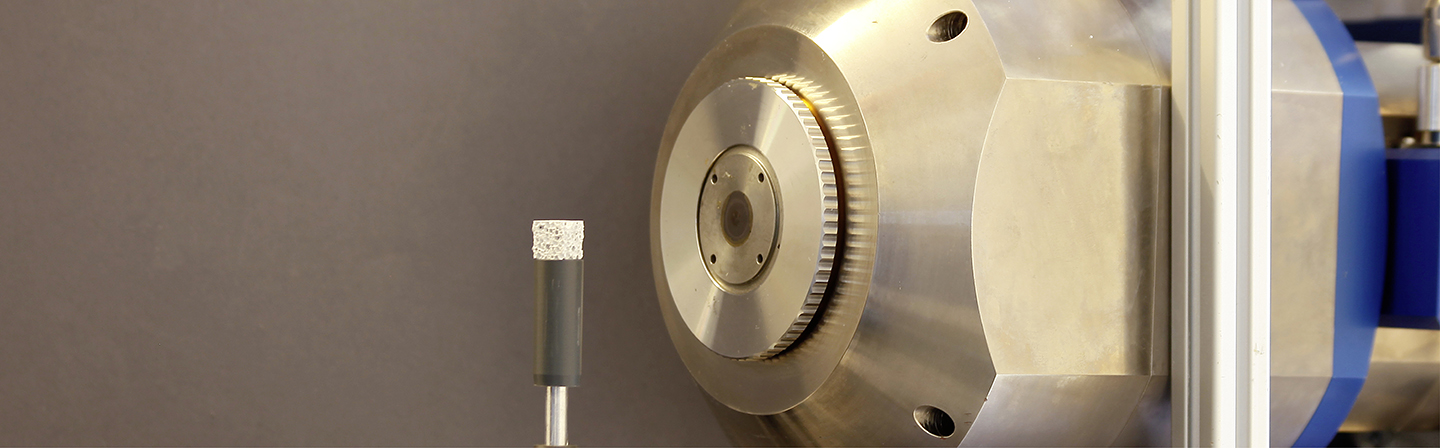

We have been running a µCT since 2008. From the beginning, it has been designed for high resolutions and soft materials. In 2014, the device underwent a major upgrade. It now features a fully accessible cabin, particularly well-suited for in-situ experiments.

Moreover, a second detector has been installed, that was originally designed for medical applications. It is highly sensitive to the low energies usually applied to image materials with low X-ray absorption.

Computed Tomography

Equipment

X-Ray Emitting Tube

- Feinfocus FXE 225 (max acceleration voltage 225 kV, max power ~20 W)

Detectors

- PerkinElmer detector with 2048 x 2048 pixels

for high energy imaging (usable up100 kV to 225 kV acceleration voltage)

- Thales detector with 3072 x 3072 pixels

for low energies (usable from 40 kV to 160 kV)

The finest nominal resolution of the CT system is 0.8 µm, the coarsest about 100 µm.

Typical Materials

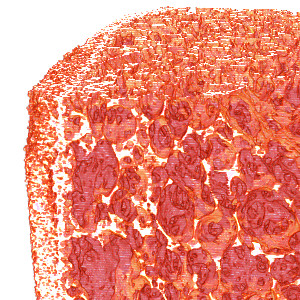

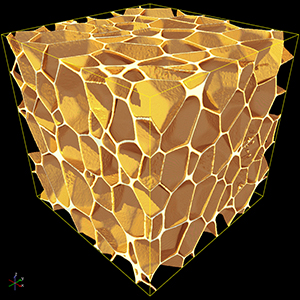

- metal foams, ceramic foams, poly-urethane foams

- other porous materials like non-woven, paper, wood-based insulation materials

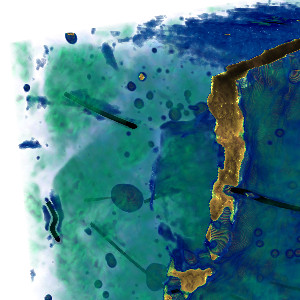

- glass fiber reinforced composites, carbon fiber reinforced composites

- leather

- concrete and mortar

Of course we measure other materials, too.

In the following we show some examples of reconstructed CT images taken with our tomograph:

PMI rigid foam. Evonik Rohacell WIND-F RC100. Pixel edge length 2.8µm

Sample Size at Desired Resolution

Thales detector:

- desired resolution in µm x 10³ x 2 = edge length of the square sample base or

- desired resolution in µm x 10³ x 2.5 = diameter of the base of the cylindrical sample

PerkinElmer detector:

- desired resolution in µm x 10³ = edge length of the square sample base or

- desired resolution in µm x 10³ x 1.5 = diameter of the base of the cylindrical sample

Example:

desired resolution 1µm required under the use of the Thales-Detektors 2 mm edge length or 2.5 mm diameter with a cylindrical sample