»DigiCell« is our measuring cell at Fraunhofer ITWM. It is available to companies and research partners for the precise and automated measurement of components – regardless of shape, material or size. Thanks to stare-of-the-art robotics, 3D scanners and optical measuring systems, we deliver reliable results with the highest accuracy. Our focus is on terahertz systems.

Measuring Cell »DigiCell« – Freeform Measurement at the Teratec Application Center

Precision in 3D With Our Component Measurement

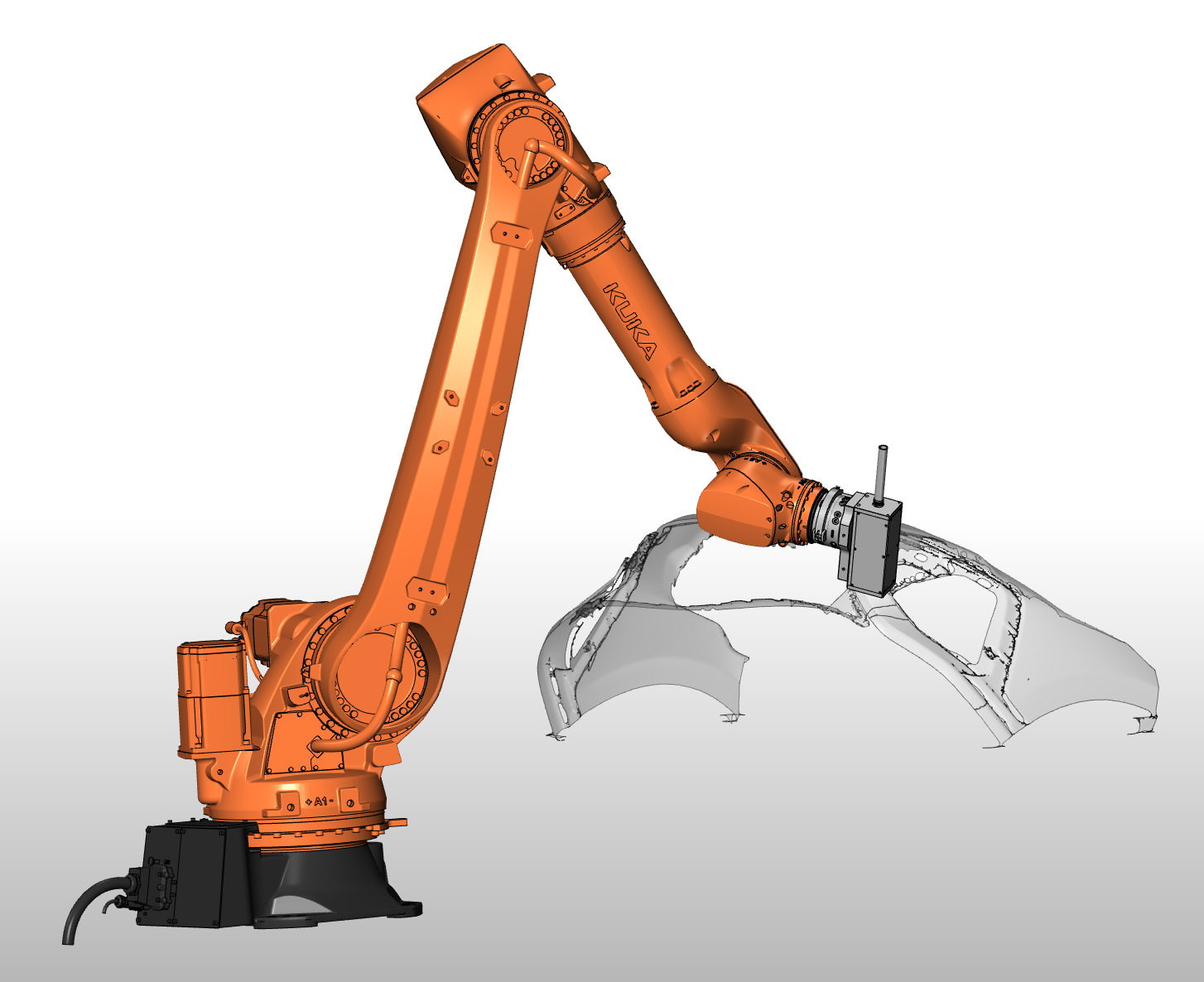

The »DigiCell« combines innovative measurement technology in a single professional measurement environment. An industrial robot, a flexible 3D measuring arm with scanners, and various optical measurement methods work together to capture components in their entirety. This allows even complex geometries to be analyzed that are virtually inaccessible with conventional measurement systems.

Why a Measuring Cell?

When aligning sensors, it is crucial that both the distance and the orientation are within the sensor tolerances. Especially for high-precision layer thickness measurements, deviations must generally be less than 1 millimeter. Sensors that are in direct contact with the component often have a suitable guide. However, this exact positioning is much more difficult to achieve for non-contact sensors. They must therefore be mounted on special devices such as tripods, scanners or robots.

For simple, flat components, an x-y gantry system can be used to measure samples selectively or in a grid pattern. More complex geometries, on the other hand, require the sensors to be positioned by robots. However, this solution requires the shape and position of the components in space to be known exactly. We developed the »DigiCell« 3D measureing cell specifically for this purpose and installed it in our laboratories.

How the Measurement Works

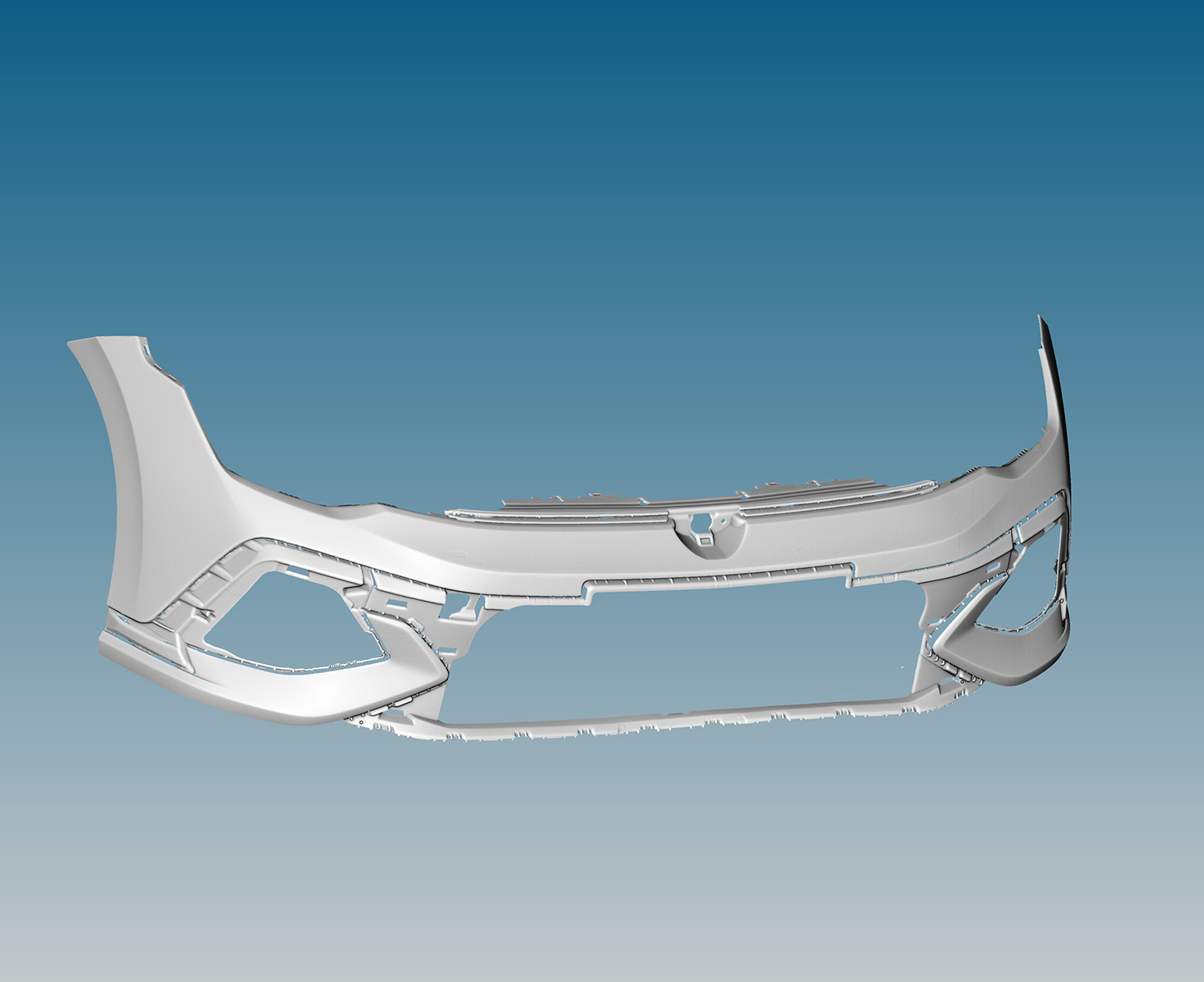

First, the component is scanned using a 3D scanner. The shape and position in space are then available as a high-precision point cloud. Based on this, specially developed software calculates the optimal robot path so that the sensor is positioned exactly at each measuring point.

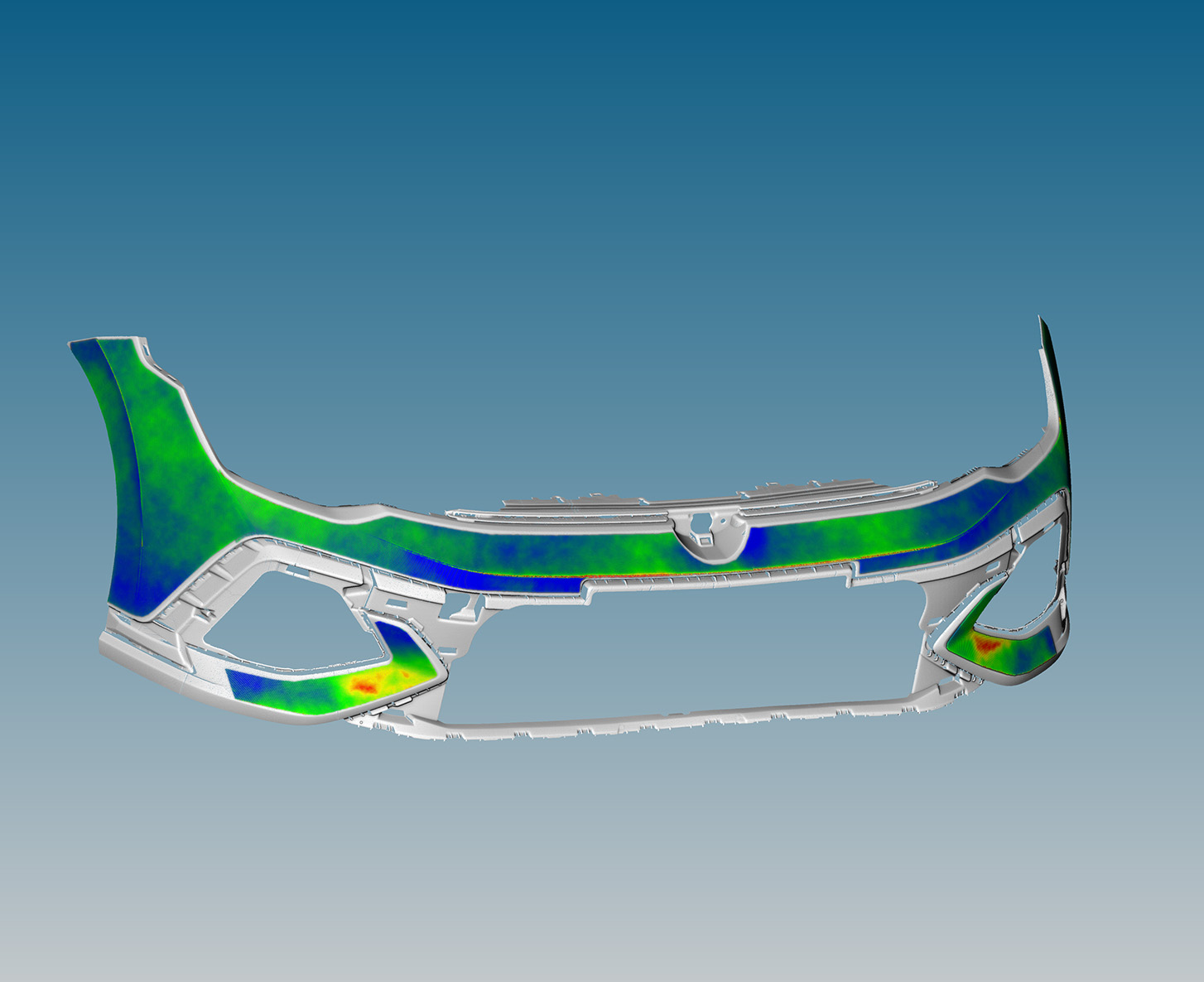

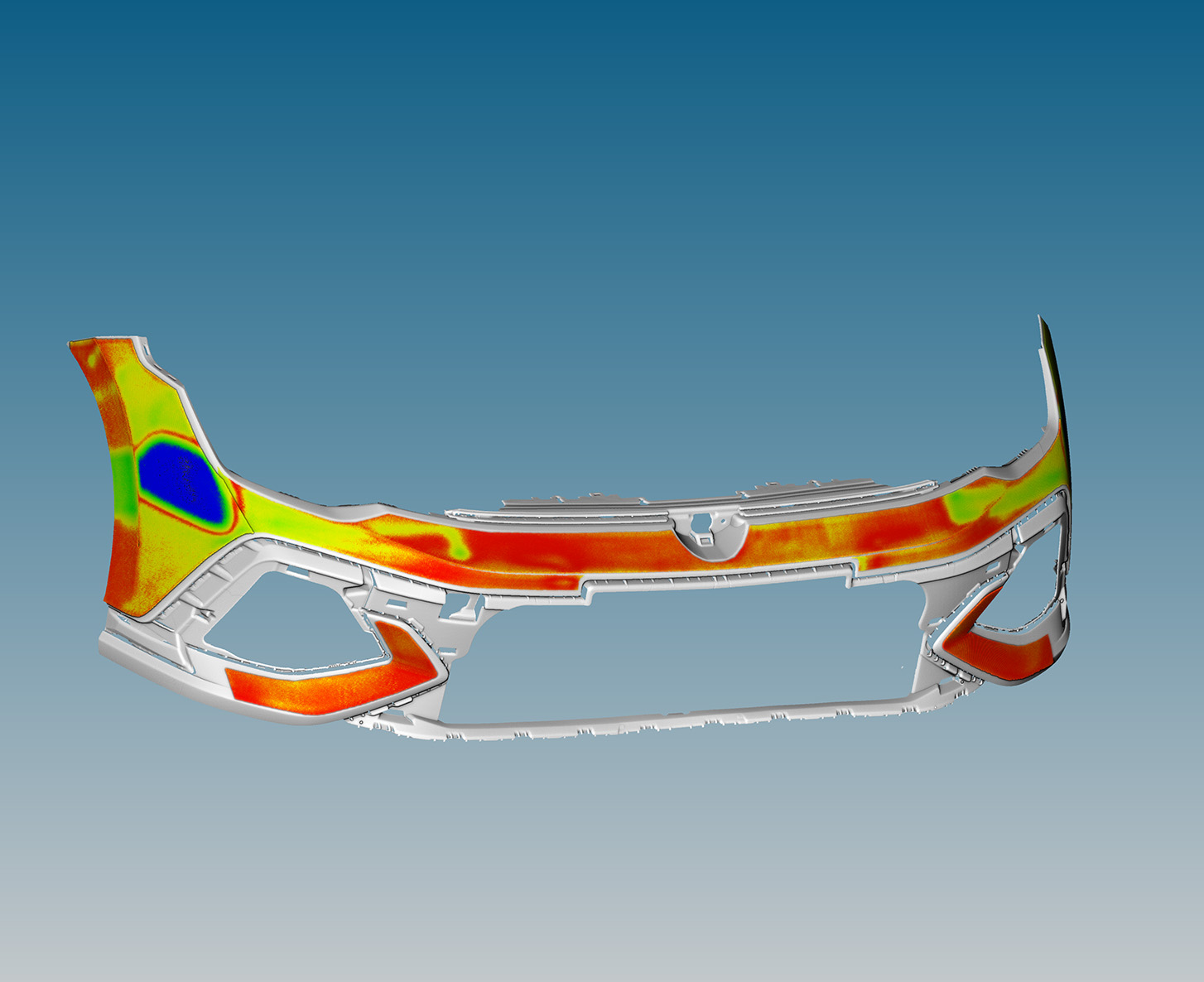

The measurement is fully automatic: the robot moves the sensor over the surface while the data is recorded in real time and linked to the robot's position information. At the end, users receive the measurement results as a 3D visualization, which provides a detailed view of the component.

Application Example

»DigiCell« is suitable for a wide range of applications in research and industry. For example, bumpers can be examined to determine both the layer thickness of the paintwork and the radar transmission at 76 GHz.

Even complex objects can be clearly displayed – point clouds of objects such as a bumper illustrate the versatility of the system. In this way, we can reliably capture a wide variety of materials and geometries. After measurement, the measurement data can be projected onto the point cloud. »DigiCell« thus offers a powerful solution for different industries and requirements.

Different sensors can be selected depending on the measurement task. Automatic path planning is then based on the selected sensor and measurement mode: single-point, raster, or continuous measurement.

Technical Equipment in Our Laboratory

Maximum component size: 2 × 1 × 1 m³

3D-Scanner:

- Manufacturer: Hexagon

- Measuring arm: Absolute Arm 85 with 7 axes

- Absolute Scanner AS 1 (line scanner)

- RS-Squared (stripe light projection)

Robot:

- Kuka KR50 R2500

- Range: 2,5 m

- Load capacity: 50 kg

Optical Measuring Systems:

- Terahertz-TDS-system with a measuring range between 5 µm and 5 mm thickness and a measuring rate up to 1,6 kHz

- Optical coherence tomography (OCT) and confocal sensors are available.

- FMCW radars for a measuring range from 100 µm to several cm and a measuring rate of up to 4 kHz