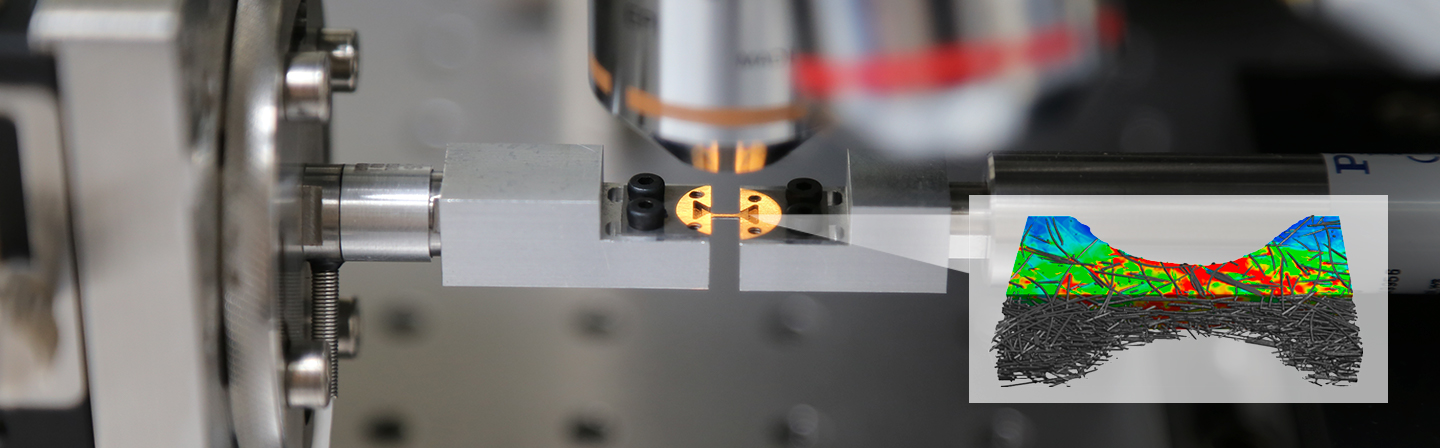

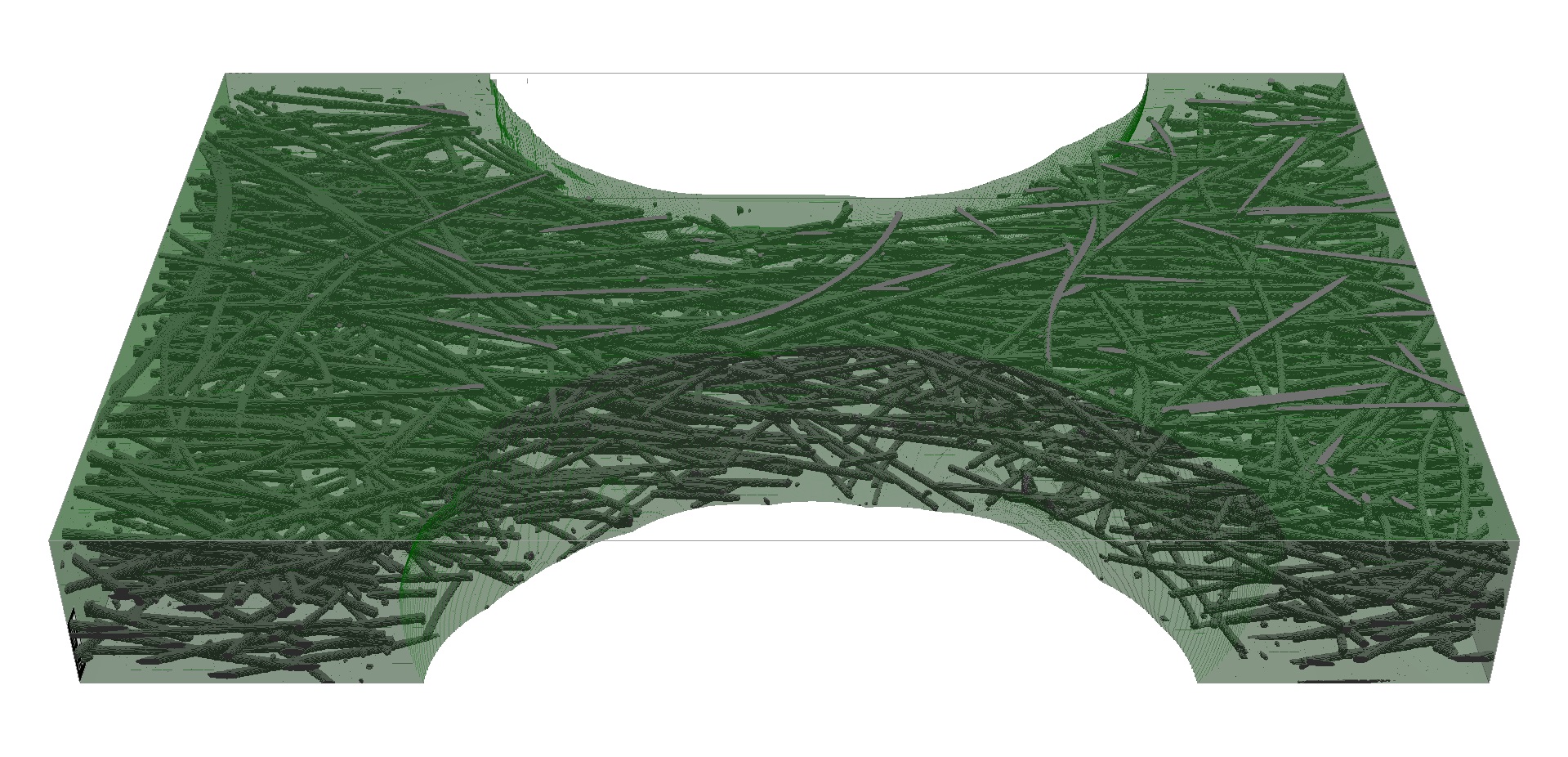

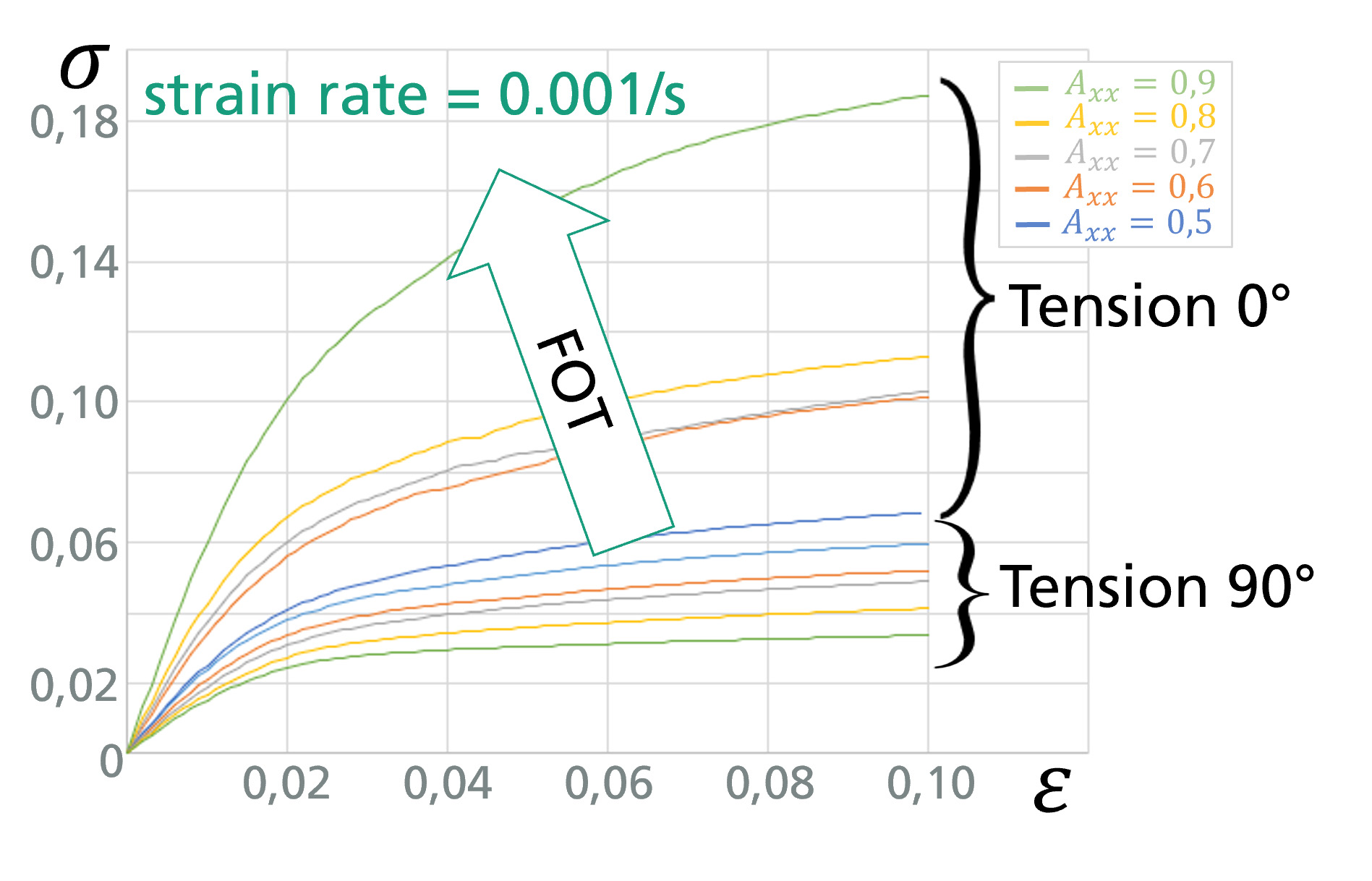

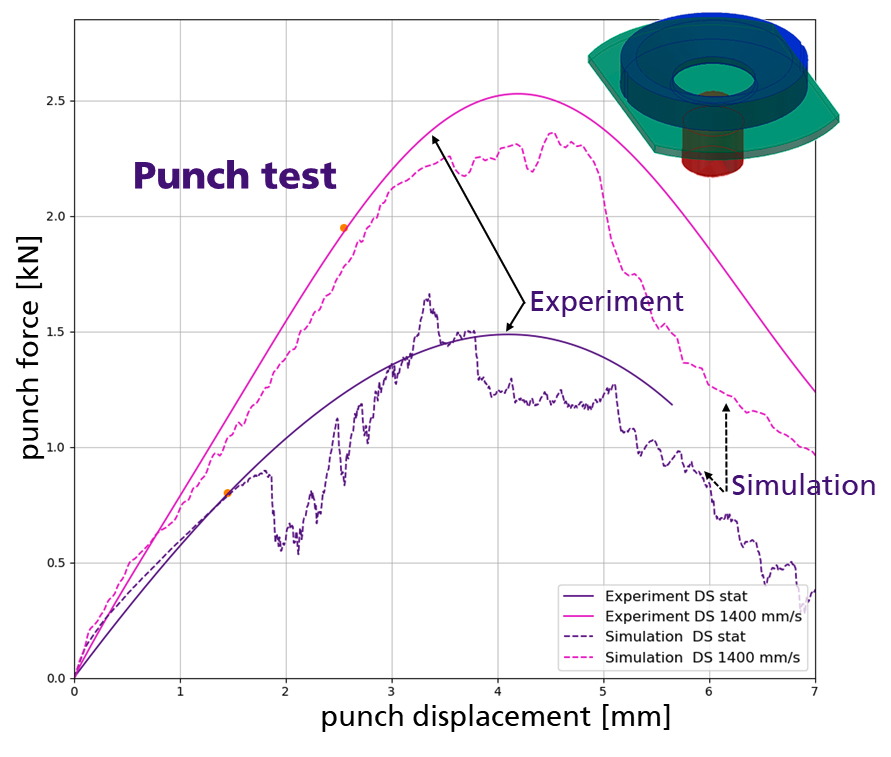

In the »REVIT« project, an Fraunhofer ITWM team is working together with the Fraunhofer Institute for Mechanics of Materials IWM to create microscale models – with the help of few micro-tensile tests and CT scans. Based on these, material cards for the mechanical characterization of fiber composites are calibrated. The resulting material model can describe the macroscopic material behavior with high accuracy.

Fiber-reinforced composites (FRP) are being used more and more frequently in areas such as the automotive industry or lightweight construction, as they can be produced quickly and offer a high degree of design freedom. Due to the short process times, fiber-reinforced injection molding and compression molding compounds made of short or long fibers in particular are widely used. Quality assessment is highly complex and requires so-called »Material Cards« which describe the specific material behavior of the FRP. Calibrating these usually requires a large number of expensive laboratory tests, which is why medium-sized companies have so far often had to rely on less precise material cards with low accuracy. In the »REVIT« project, a method was developed to offer small and mid-sized enterprises (SME) a much more efficient and cost-effective solution for this challenge.

The behavior of FRP components under load depends on the orientation of the fibers within the plastic material. Therefore, it is necessary to determine the dependence of the material behavior on the fiber orientation as precisely as possible. This is already possible today, but usually about 250 material tests have to be carried out for this purpose. We – Fraunhofer ITWM experts from the departments »Flow and Material Simulation« and »Image Processing« as well as a team from Fraunhofer IWM – are working on replacing this process by a few physical tests in combination with virtual measurements.