The chemical industry has been considered a driver of progress in Germany for more than 100 years. In the KEEN project, stakeholders are working together to take the experience of the knowledge-based industrial world in new directions with the possibilities of artificial intelligence. Because one thing is clear: »AI alone will not work. It's a matter of bringing knowledge and data together to unleash benefits in practice,« says PD Dr. Michael Bortz.

Project KEEN: AI Meets 100 Years of Engineering

Innovation Platform KEEN Unites Start-ups, Corporations and Research Institutions

What if …

For this purpose, there are two subprojects at Fraunhofer ITWM: In the first step, substances and substance mixtures have to be modeled so that AI can be used for a prediction of substance properties. In the second step, process simulations are carried out. »Only when we know how substances behave can we even design a process for separation, for example,« says Bortz.

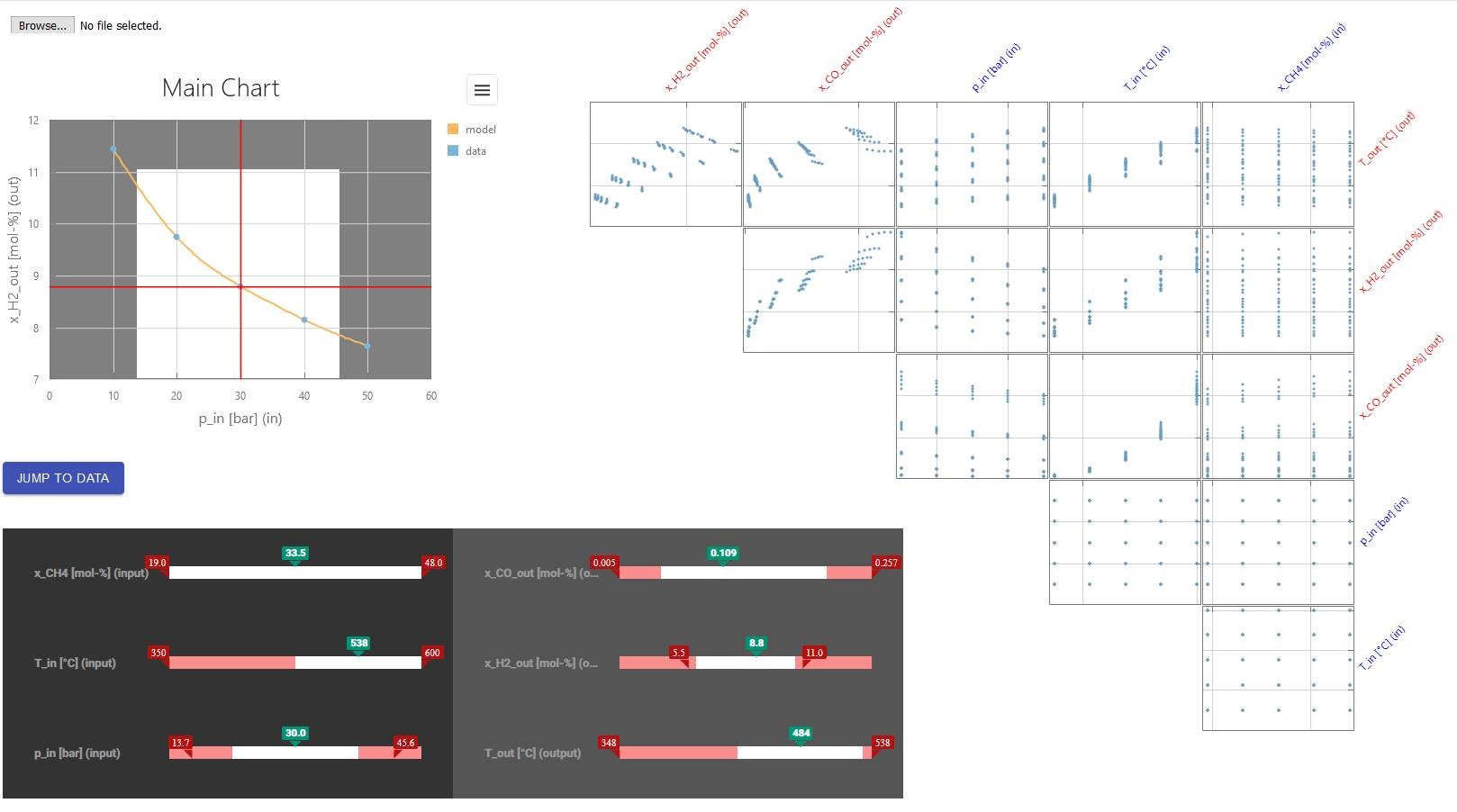

Specifically, the team is working on a decision support system that can run »what-if« scenarios in real time. By using AI, it is possible to display the effects of changes in the process in real time, even in computationally intensive and time-consuming process simulations. »We set up AI models that are trained from simulation data and can then calculate considerably faster and even be capable of real-time,« Bortz describes the vision.

What-if scenarios are important for practice, as they can be used to anticipate situations before they actually occur: How should I run a cooling-intensive process if the river water I use to cool the process gets too warm in a hot summer? How should process settings be changed if the composition or even the price of raw materials changes? If questions like these are answered reliably before the event occurs, it is possible to react quickly in an emergency – without compromising raw material efficiency and product quality.

Half-Time in the Project: Three Software Prototypes Developed

After a development phase of several months, the project participants of Fraunhofer ITWM have delivered three software prototypes for evaluation. For the software prototype »LAMBDa« (Lovely Analyzer of Models and Big Data), a neural network was trained so that processes can be optimized by artificial intelligence (AI). »Usually, forward planning is done: engineers change certain factors and then evaluate the impact on their product. We have reversed this approach. The software answers the question: 'I want the following product, how do I have to manage the plant for it?« says Bortz. Interactive user interface elements help users to playfully identify optimal operating points for their needs and in this way to understand the influence of the various degrees of freedom.

Another software prototype supports the decision-makers in an interactive time series analysis. The aim is to distinguish between usable and unusable data for further analysis. This decision is strongly dependent on the context and the use of the data. This is why the ITWM team has decided on an interactive approach: The user is supported in the data analysis in order to quickly get an overview of the entire data situation and to identify weaknesses in the data. Interactive features include outlier analysis based on robust statistics, stationarity analysis and filters for scatterplots. The application shows that many time series that extend over longer periods can be recorded in a short time and the information that is important for the further steps can be extracted in a way that is suitable for use.

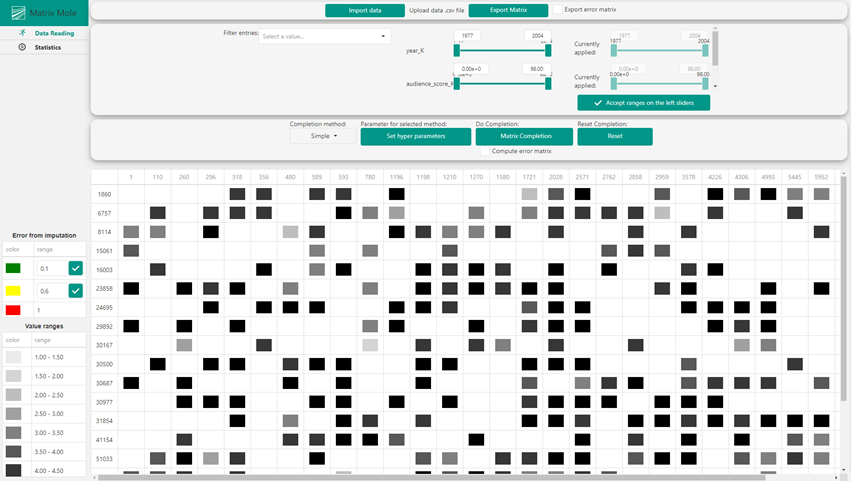

The software prototype »MatrixMole« makes it possible to complete a matrix that maps substance properties and makes statements about thermodynamic properties of binary substance mixtures. In addition, metadata in the form of pure substance properties such as polarity are offered as interactive filters. As a result, not only are statements made about mixtures of substances that have not been measured (gaps in the matrix), but the uncertainties of the predictions are also quantified. »In this way, the software recognizes in advance of expensive measurement procedures in which area measurements are most informative, i.e., are actually worthwhile.«

What-if scenarios are important for practice, as they can be used to anticipate situations before they actually occur: How should I run a cooling-intensive process if the river water I use to cool the process gets too warm in a hot summer? How should process settings be changed if the composition or even the price of raw materials changes? If questions like these are answered reliably before the event occurs, it is possible to react quickly in an emergency – without compromising raw material efficiency and product quality.

Project Partners:

Innovative End Users

- Air Liquide Forschung&Entwicklung GmbH, Frankfort Main

- Bayer AG, Leverkusen

- Covestro Deutschland AG, Leverkusen

- Evonik Operations GmbH, Essen

- Merck KGaA, Darmstadt

Established technology providers

- ABB AG, Ladenburg

- KROHNE Innovation GmbH, Duisburg

- SAMSON AG, Frankfurt am Main

Agile KMU/Start-ups

- Capital-Gain Consultants GmbH, Berlin

- DDBST, Oldenburg

- LeiKon GmbH, Herzogenrath

- INOSIM Consulting GmbH, Dortmund

- X-Visual Technologies GmbH, Berlin-Adlershof

Associations

- DECHEMA e.V., Frankfurt am Main

- GVT, Frankfurt am Main

- NAMUR, Leverkusen

Associated Partners

- MetaTwin GmbH, Dortmund

- ViSenSys GmbH, Dortmund

Project Duration:

The project is designed for the period from 01.04.2020-2023.

Project Type:

KEEN is 60 percent funded by the German Federal Ministry for Economic Affairs and Energy and has total funding of 23 million euros.