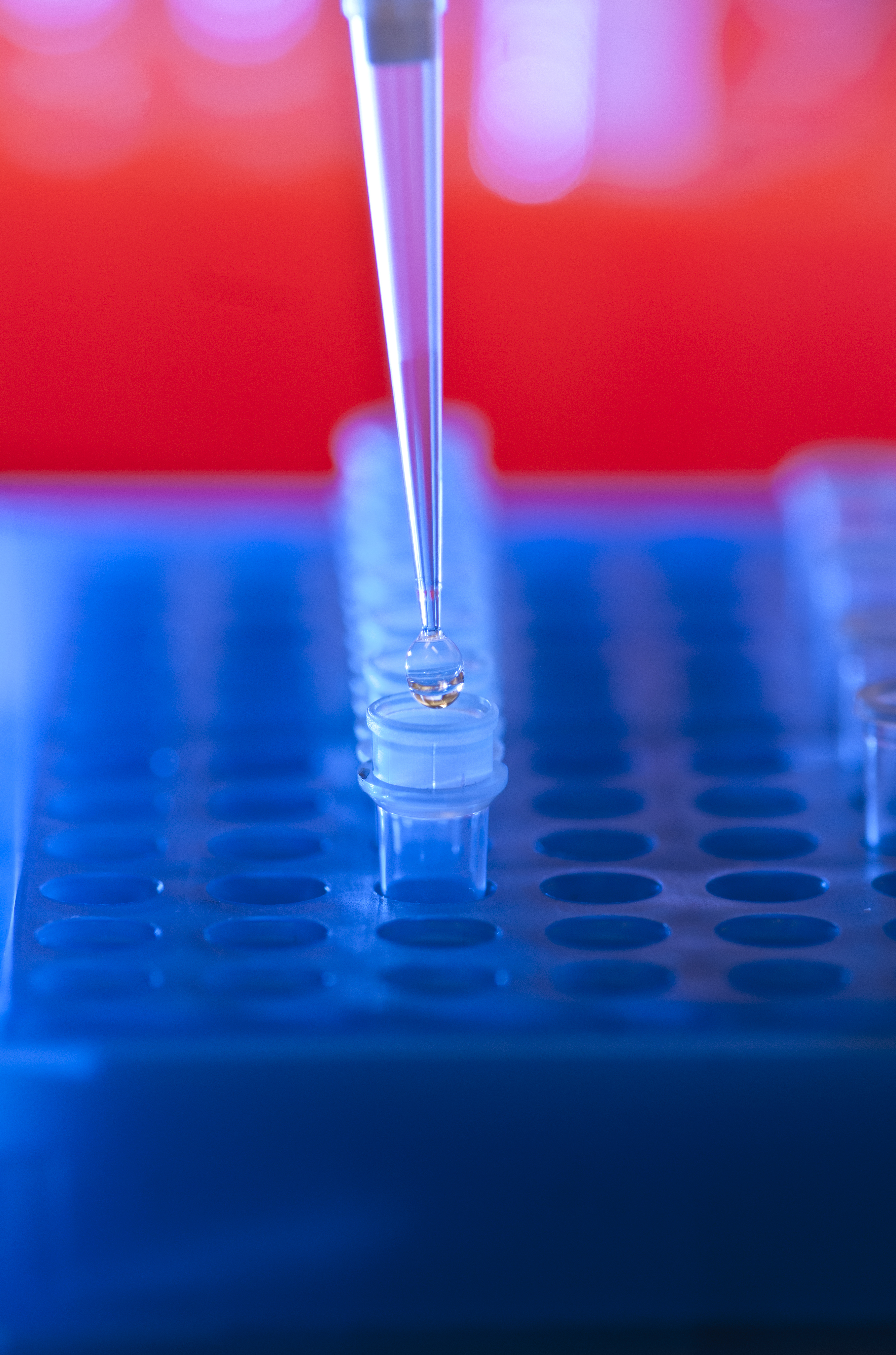

Personalized therapies and medicine are new and promising trends for the treatment of many diseases. They have been proven exceptionally effective in low scale tests. However, in order to succeed economically, the production processes need to be scaled to an industrial level. They need to be secure, cost efficient and last, but not least, fast. After all, long waits will be unacceptable for patients – especially in life and death situations. Therefore, it is of the essence that the production is planned and executed optimally.

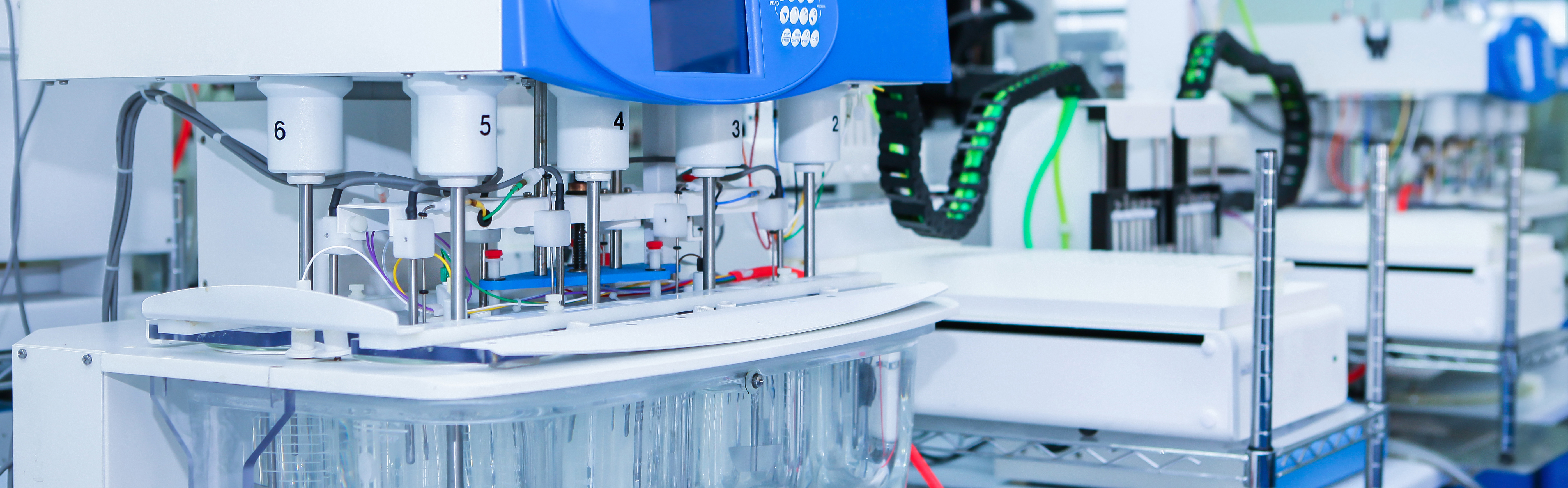

Challenges of Bio-Processes

Bio-processes show characteristics that complicate the optimal design and efficient management of industrialized processes and thus make the production of personalized medicin more expensive:

- High quality standards often call for re-executing process phases for individual patients

- Heterogeneous processing times complicate the development of a periodic production flow

- The probabilistic nature of processing times and error occurrence prevent a structured, predictable workflow